Strong-adsorption salt-resistant blocking agent based on nano silicon dioxide and water-based drilling fluid

A technology of nano-silica and water-based drilling fluid, which is applied in the field of water-based drilling fluid, can solve problems such as well wall instability, and achieve the effects of enhanced plugging performance, enhanced adsorption performance, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

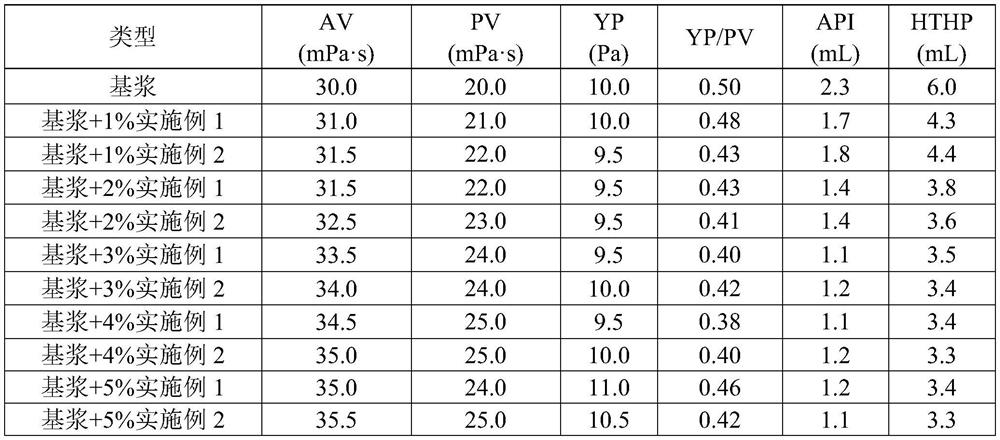

Embodiment 1

[0024] S1. Weigh 1 mole of nano-silica in 120 mL of absolute ethanol, disperse it ultrasonically for 30 minutes, add hydrochloric acid solution to adjust the pH value to 5, and then add 2.5 moles of γ-aminopropyltriethoxysilane to obtain a mixed solution. Stir the mixture at 60°C for 3.5 hours, put it into a centrifuge after the reaction, centrifuge at 5000rpm for 5min, then filter, and then wash the solid matter with deionized water and absolute ethanol for 3 times, and finally, the solid Vacuum drying in an oven at 60°C for 24 hours to obtain modified nano-silica;

[0025] S2. Introduce 120ml of methyl acetate into a 250mL round-bottomed three-necked bottle, add 1 mole of modified nano-silica, and ultrasonically disperse for 30 minutes, then add 2.5 moles of D-alanine methyl ester hydrochloride, and then Add 1 mole of O-(7-azabenzotriazol-1-yl)-N,N,N',N'-tetramethyluronium tetrafluoroborate quaternary ammonium salt, cool and reflux at 60°C for 6 hours , followed by washing ...

Embodiment 2

[0029] S1. Weigh 0.5 mole of nano-silica in 100mL of absolute ethanol, disperse it ultrasonically for 30 minutes, add hydrochloric acid solution to adjust the pH value to 5, and then add 1.5 mole of N-β-(aminoethyl)-γ-aminopropyl Trimethoxysilane was used to obtain a mixed solution, and the mixed solution was stirred at 60°C for 3.5 hours. After the reaction, it was placed in a centrifuge, centrifuged at a speed of 5000 rpm for 5 minutes, then filtered, and then washed with deionized water and absolute ethanol The solid material was processed 3 times, and finally, the solid was vacuum-dried in an oven at 60°C for 24 hours to obtain modified nano-silica;

[0030]S2. Introduce 120ml of methyl acetate into a 250mL round-bottomed three-necked bottle, add 0.5 mole of modified nano-silica, and ultrasonically disperse for 30min, then add 1.5 mole of D-alanine methyl ester hydrochloride respectively, and then Add 0.5 mole of O-(7-azabenzotriazol-1-yl)-N,N,N',N'-tetramethyluronium tetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com