Inorganic-organic hybrid photoelectrochromic material as well as preparation method and application thereof

An organic hybridization and chromogenic technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, optics, etc., can solve the problems of low coloring efficiency, complex components, cumbersome preparation steps, etc., and achieve good photochromic effect and preparation process Simple, easy-to-composite effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

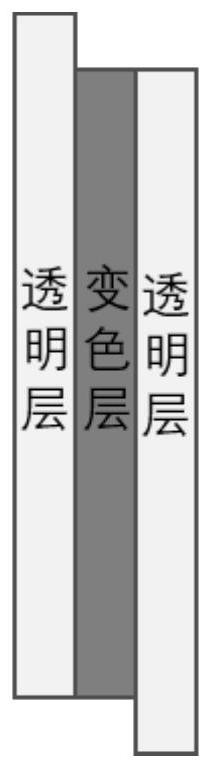

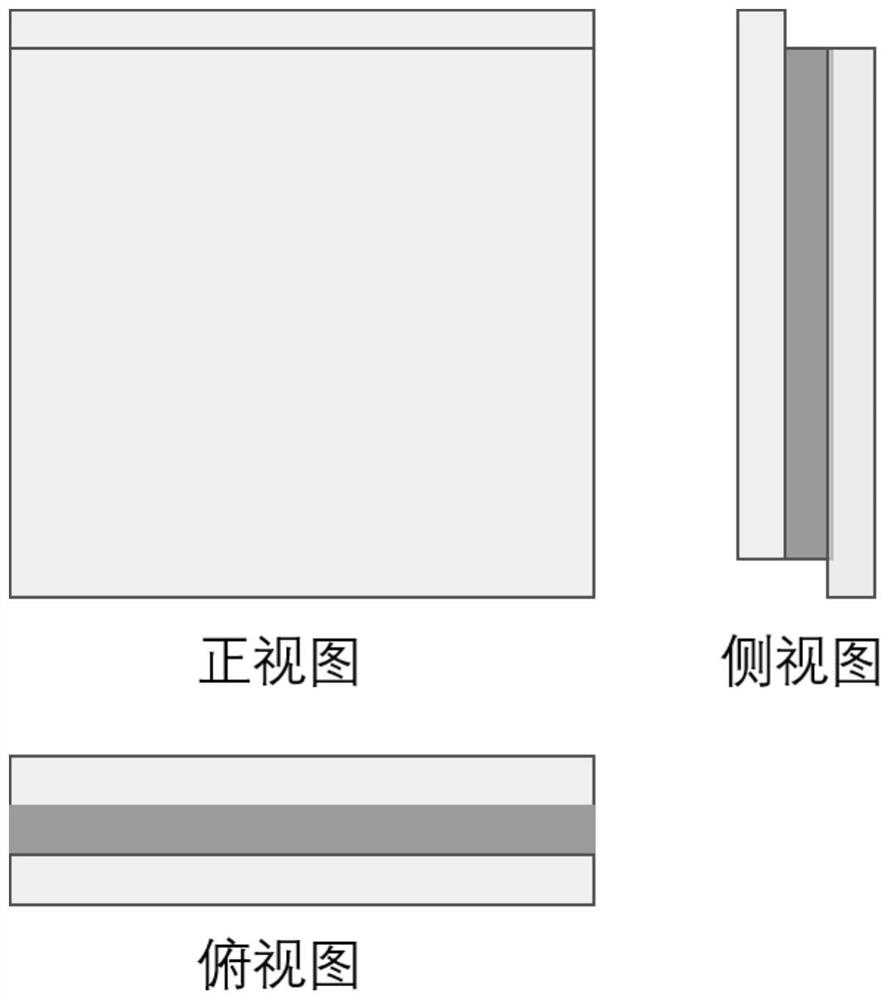

[0033] Dissolve 3g of sodium tungstate in 40mL of distilled water, slowly drop into 3mL of 2,6-lutidine, stir for half an hour, the solution gradually becomes clear from turbidity, then add 1mol / L hydrochloric acid drop by drop, adjust the pH to 5.6, As hydrochloric acid was dripped in, white flocs were gradually produced and dissolved by stirring. The exothermic reaction caused the temperature of the outer wall of the container to rise, and then heated to 60°C for 8 hours. The reaction precipitate was collected every 2 hours, and a total of 4 precipitates were collected. The precipitate was dried in an oven at 80°C to obtain a white powder precipitate. Dissolve 1 g of the precipitate in 10 mL of PC (propylene carbonate) and ultrasonically homogenize to obtain a color-changing liquid. Paste two pieces of glass together with double-sided tape to build an interlayer, use capillary phenomenon to fill the discoloration liquid into the interlayer and seal it to complete the package...

Embodiment 2

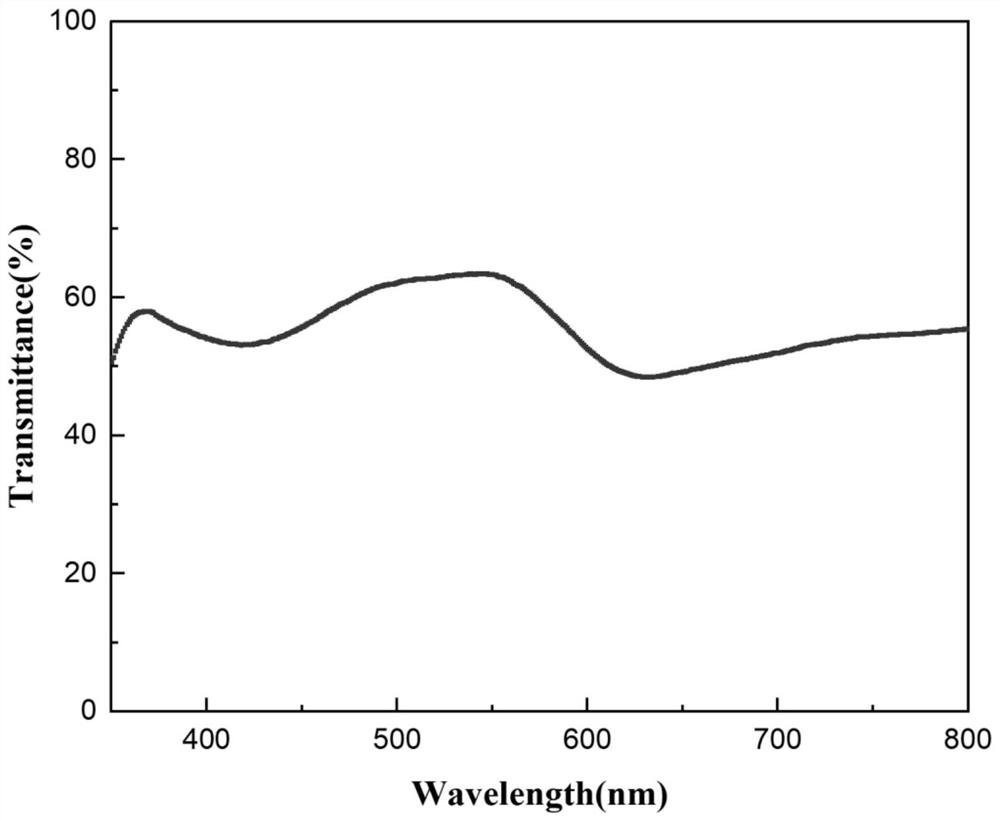

[0035] Dissolve 3g of sodium tungstate in 40mL of distilled water, add 10mL of 2mol / L hydrochloric acid, the solution gradually turns yellow, then add ethylenediamine dropwise to adjust the pH to 5.6, with the addition of ethylenediamine, gradually white flocculent The reaction was violently exothermic, and the temperature of the outer wall of the container rose significantly, and then heated to 60°C to react, and the reaction precipitate was collected every 2 hours, and a total of 4 precipitates were collected. The precipitate was dried in an oven at 80°C to obtain a white powder precipitate. Dissolve 1 g of the precipitate in 10 mL of PC (propylene carbonate) and ultrasonically homogenize to obtain a color-changing liquid. Paste two pieces of glass together with double-sided tape to build an interlayer, use capillary phenomenon to fill the discoloration liquid into the interlayer and seal it to complete the package. Put the packaged device under a 5W ultraviolet lamp and ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com