Yeast exopolysaccharide, preparation method and application thereof

An extracellular polysaccharide and yeast technology, applied in the field of microorganisms, can solve the problems of high production cost, low yield and the like, achieve the effect of simple and efficient preparation method, and protect Lactococcus lactis from freeze-drying damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1. Preparation of exopolysaccharide of Saccharomyces ruxii of the present invention

[0050] (1) Activate and expand the culture of Zygosaccharomyces rouxii CGMCC No.3791;

[0051] (2) Inoculate the expansion culture solution prepared in step (1) into the fermentation medium with an inoculum size of 5%, and culture it statically at 30° C. for 60 hours to obtain a fermentation solution containing exopolysaccharide of Saccharomyces ruxii;

[0052] The fermentation medium consists of the following components: yeast extract 1g, peptone 2g, glucose 2g, distilled water 100mL;

[0053] (3) centrifuging the liquid fermentation broth prepared in step (2), and collecting the supernatant;

[0054] (4) adding trichloroacetic acid with a final concentration of 3-8% to the supernatant obtained in step (3), stirring at room temperature for half an hour, centrifuging, and collecting the supernatant;

[0055] (5) adding three times the volume of absolute ethanol to the supe...

Embodiment 2

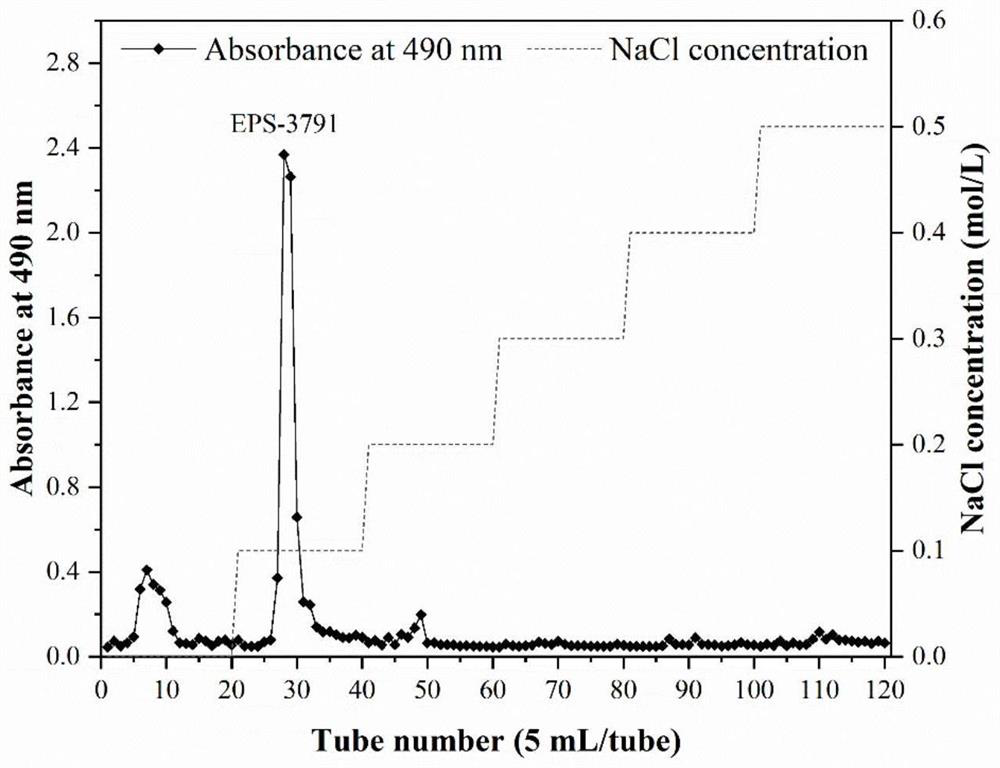

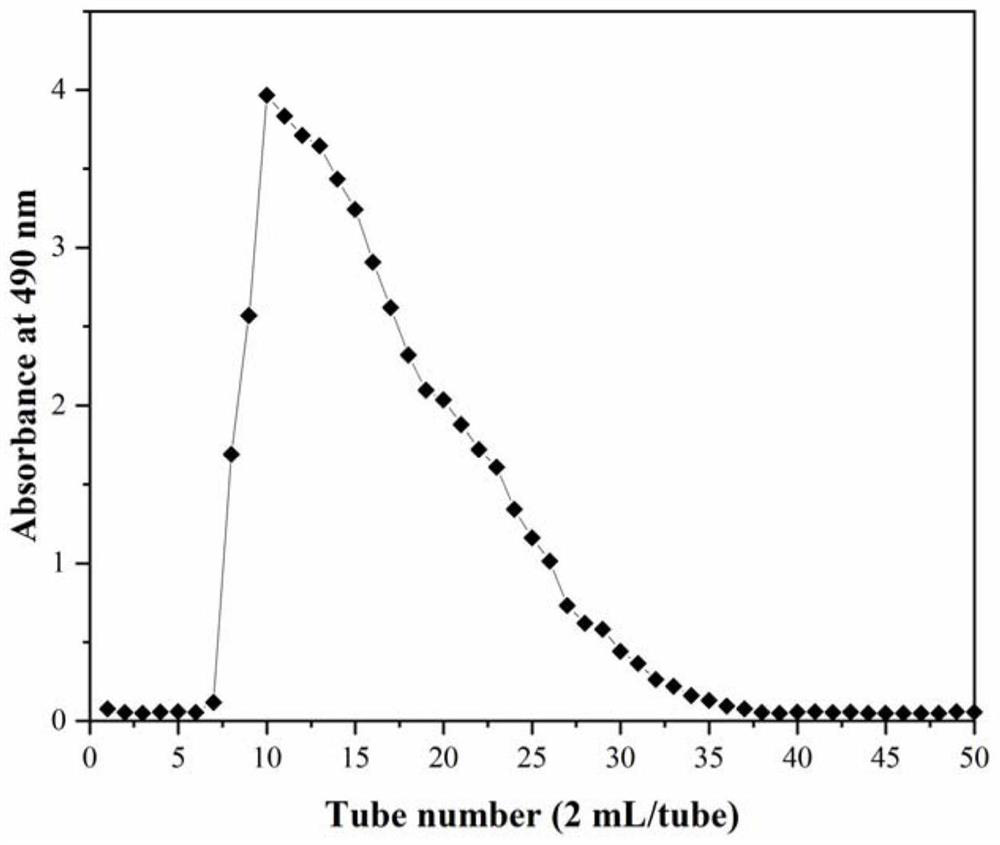

[0062] Embodiment 2. Identification of exopolysaccharide of Saccharomyces ruxii of the present invention

[0063] 2.1 Molecular weight determination

[0064] Specific steps are as follows:

[0065] (1) Dissolve the EPS-3791 obtained in Example 1 in 0.1M NaNO 3 In aqueous solution to a final concentration of 1 mg / mL, and filtered through a filter with a pore size of 0.45 μm;

[0066] (2) Inject the filtrate (100 μL) prepared in step (1) into a gel exclusion chromatography column (Ohpak SB-805HQ (300×8mm), Ohpak SB-804HQ (300×8mm), Ohpak SB-803HQ (300×8mm), 8mm)), eluted with sodium nitrate solution (0.1M) at a flow rate of 0.4mL / min, and the column temperature was 45°C to obtain the response value data;

[0067] (3) Collect and process the obtained data, and calculate the molecular weight according to the Mark-Houwink Equation.

[0068] The measurement result is: the average molecular weight of EPS-3791 is 64.412KDa.

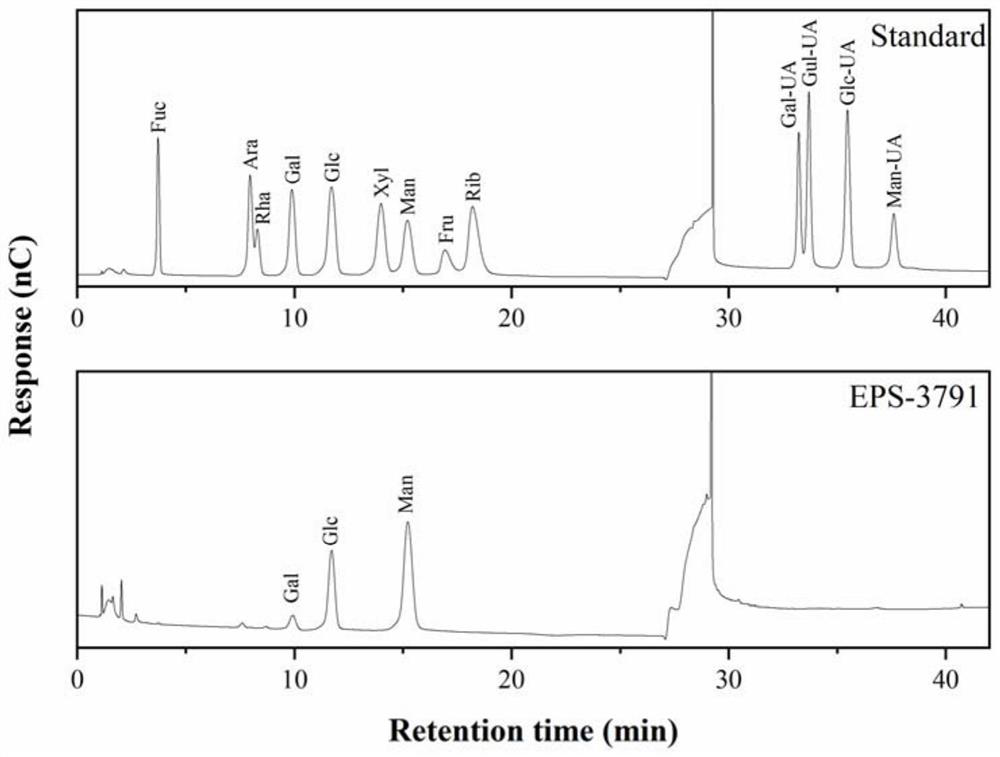

[0069] 2.2 Determination of the composition of monosac...

Embodiment 3

[0084] Embodiment 3. The function of exopolysaccharide of Saccharomyces rouxii of the present invention

[0085] 3.1 Low-temperature protective effect of the exopolysaccharide EPS-3791 of Saccharomyces ruckeri of the present invention on Lactococcus lactis

[0086] Specific steps are as follows:

[0087] (1) Take 1 mL of the mid-log phase fermentation broth of Lactococcus lactis MG 1363, centrifuge (8 000 g, 4°C, 5 min), and discard the supernatant;

[0088] (2) Add 1 mL of 0.9% normal saline (group without any protective agent), 20% glycerin, 1% EPS, 3% EPS, 5% EPS aqueous solution, shake well;

[0089] (3) Freeze at -80°C for 7 days, thaw, calculate the number of viable bacteria by the dilution coating plate method, and the survival rate is expressed as the percentage of the number of viable cells after freezing relative to the number of viable cells before freezing.

[0090] The measurement results are as follows: Figure 5 As shown in middle a, after 7 days of cryogenic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com