Non-aqueous electrolyte for lithium battery and lithium ion battery

A non-aqueous electrolyte and lithium-ion battery technology, applied in the field of electrolyte, can solve the problems of increasing the cost of electrolyte, difficulty in exporting, large initial DC impedance and DC impedance, etc., to improve high-temperature cycle and capacity recovery rate, and improve The effects of lithium-conducting ability and high film-forming sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of secondary lithium battery of the present invention is as follows:

[0051] (1) Preparation of non-aqueous electrolyte for lithium batteries

[0052] In a dry argon atmosphere, configure a non-aqueous solvent, add fully dried electrolyte salt, lithium salt additive, non-aqueous solvent and additives, and mix uniformly to obtain a non-aqueous electrolyte for lithium batteries.

[0053] (2) Preparation of secondary lithium battery

[0054] The electrolyte solution obtained in step 1) is used as a non-aqueous electrolyte solution for lithium batteries to prepare secondary lithium batteries.

[0055] Among them, the positive electrode material is as follows:

[0056] 811 (referred to as 8 series) means Li 2 Ni 0.8 co 0.1 mn 0.1 o 2 ;

[0057] LFP (LiFePO 4 abbreviation) means lithium iron phosphate.

[0058] The negative electrode material is graphite or carbon silicon.

Embodiment 1

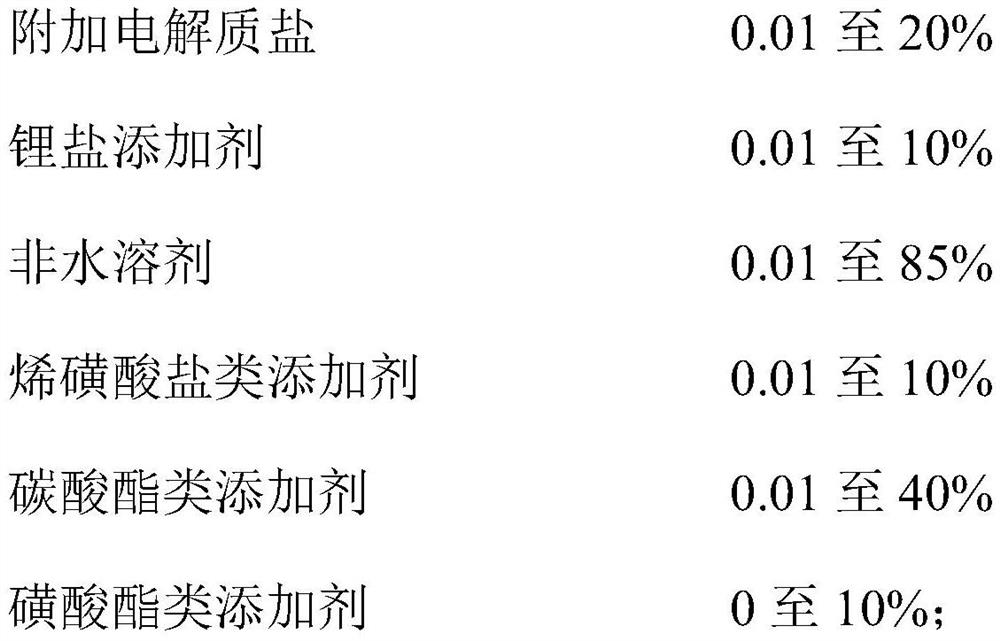

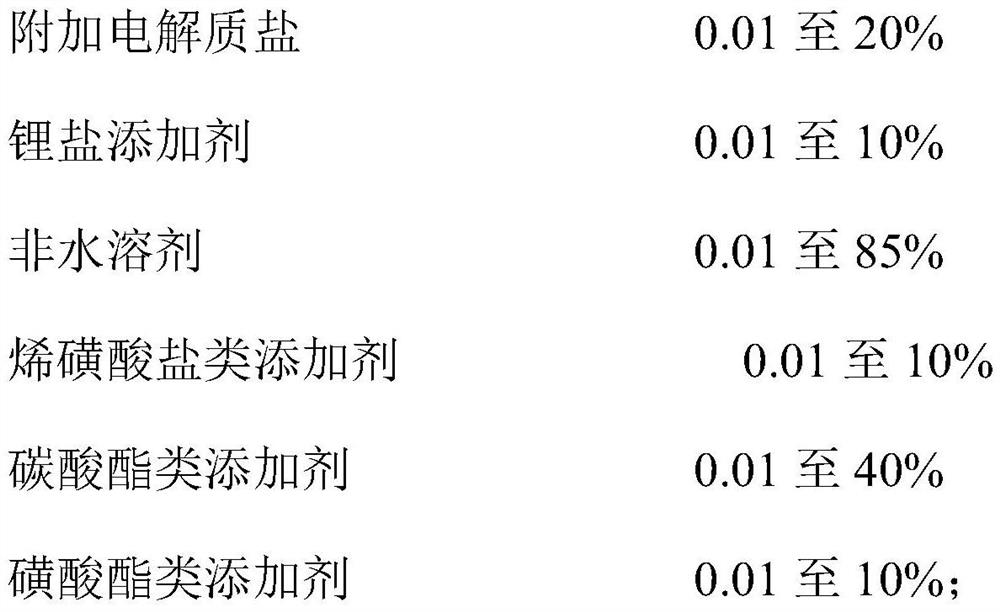

[0060] The lithium battery non-aqueous electrolytic solution of the present embodiment comprises the following components by weight percentage:

[0061]

[0062] Wherein, the non-aqueous solvent is a mixture of EC, EMC and DEC with a mass ratio of 3:5:2, and the structural formula of the alkene sulfonate additive is Record it as A.

[0063] The structural formula of another alkene sulfonate additive is Record it as B.

[0064] In addition, the non-aqueous solvents in Examples 2-14 and Comparative Examples 1-6 are mixtures of EC, EMC and DEC with a mass ratio of 3:5:2.

[0065] In other embodiments and comparative examples, parameters were changed on the basis of Example 1, and the parameters for specific changes are shown in Table 1.

[0066] Table 1

[0067]

[0068]

[0069] The lithium batteries prepared in Examples 1-14 and Comparative Examples 1-6 were tested for performance, and the test results are shown in Table 2.

[0070] Wherein, the secondary batter...

Embodiment 12

[0084] Example 12 without adding DTD, Example 13 without adding PS, and Example 14 without adding DTD and PS at the same time, the battery still has low battery impedance and excellent cycle performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com