Preparation method of magnesium ion battery positive electrode material

A magnesium ion battery and positive electrode material technology, applied in the field of preparation of magnesium ion battery positive electrode materials, can solve the problems of harsh preparation process, high raw material purity and production equipment requirements, and achieve low specific capacity, slow diffusion kinetics, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] One, a kind of preparation method of positive electrode material of magnesium ion battery

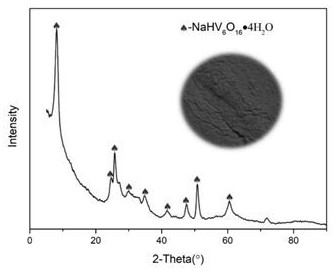

[0038] In the prior art, sodium vanadium polyacid / vanadium polyacid has a unique porous layered structure and interlayer structure water, and its porous layer structure can provide fast intercalation / extraction transport channels for magnesium ions, and its interlayer structure water can Shielding the strong electrostatic interaction between the guest magnesium ions and the lattice framework, the diffusion kinetics of magnesium ions in it is excellent, which can solve the problem of slow diffusion kinetics of magnesium ions in the cathode materials of traditional magnesium ion batteries. At the same time, the support of structural water can keep the porous layered structure stable, which can solve the problem of poor cycle performance of traditional magnesium-ion battery cathode materials. Moreover, the valence state of active vanadium is changeable, and a single vanadium atom can...

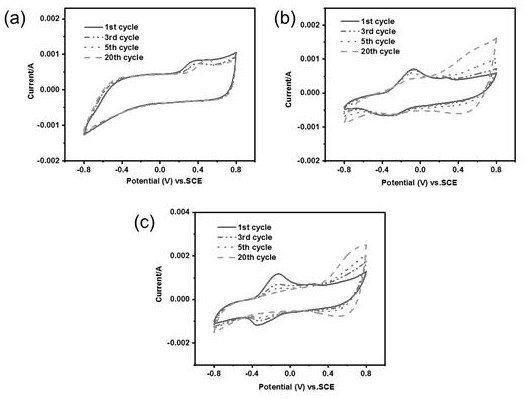

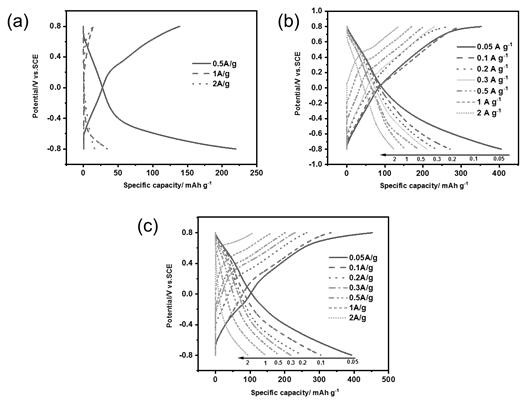

Embodiment 1

[0040] (1) Desiliconization of sodium vanadate solution: 50 mL sodium vanadate solution (the content of vanadium element is 41.79 g / L, the content of silicon element is 1.2585 g / L), adjust the pH of sodium vanadate solution with sulfuric acid to 3.2 , add 0.2 g of anionic polyacrylamide CPAM, stir the reaction at room temperature at a stirring speed of 200 r / min for 30 min, let it stand for 14 h, filter, wash the filter residue with deionized water 2 to 3 times, and filter twice. The measured desiliconization rate is 84.37%, the vanadium loss rate is 1.24%, and the filtrate is called vanadium qualified liquid;

[0041] (2) Vanadium precipitation of sodium salt of qualified vanadium solution: at room temperature, add the qualified vanadium solution dropwise into 0.5mol / L sulfuric acid solution while stirring until the pH of the mixed solution is 1.6, and put the mixed solution at T=90℃ , stirred and reacted at a stirring speed of 200r / min for 60min, the solution was naturally c...

Embodiment 2

[0043] (1) Desiliconization of sodium vanadate solution: 50mL sodium vanadate solution (the content of vanadium element is 41.79g / L, the content of silicon element is 1.2585g / L), adjust the pH of sodium vanadate solution with sulfuric acid=3.2, Add 0.2g of anionic polyacrylamide CPAM, stir and react at room temperature for 30min at a stirring speed of 200r / min, let stand for 14h, filter, wash the filter residue 2~3 times with deionized water, and filter twice. The measured desiliconization rate is 84.21%, the vanadium loss rate is 1.15%, and the filtrate is called vanadium qualified liquid;

[0044] (2) Vanadium precipitation of sodium salt of qualified vanadium solution: at room temperature, add qualified vanadium solution dropwise into 0.5mol / L sulfuric acid solution while stirring until the pH of the mixed solution is 1.8, and put the mixed solution at T=90℃ , stirred and reacted at a stirring speed of 200r / min for 60min, the solution was naturally cooled to room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com