Liquid metal multi-sample constant load stress corrosion test device and method

A liquid metal and stress corrosion technology, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, and the use of stable tension/pressure to test the strength of materials, etc., can solve problems such as single function, influence of material mechanical properties, erosion, etc. , to achieve the effect of simple loading structure, uniform load and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention is further described below by drawings and specific embodiments.

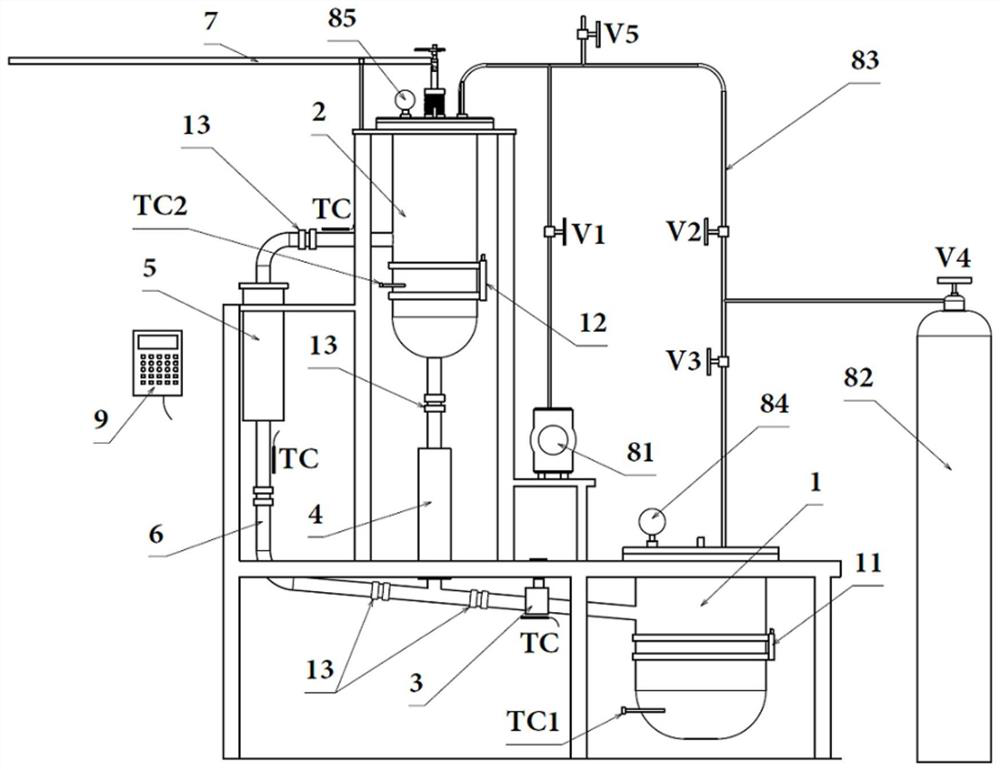

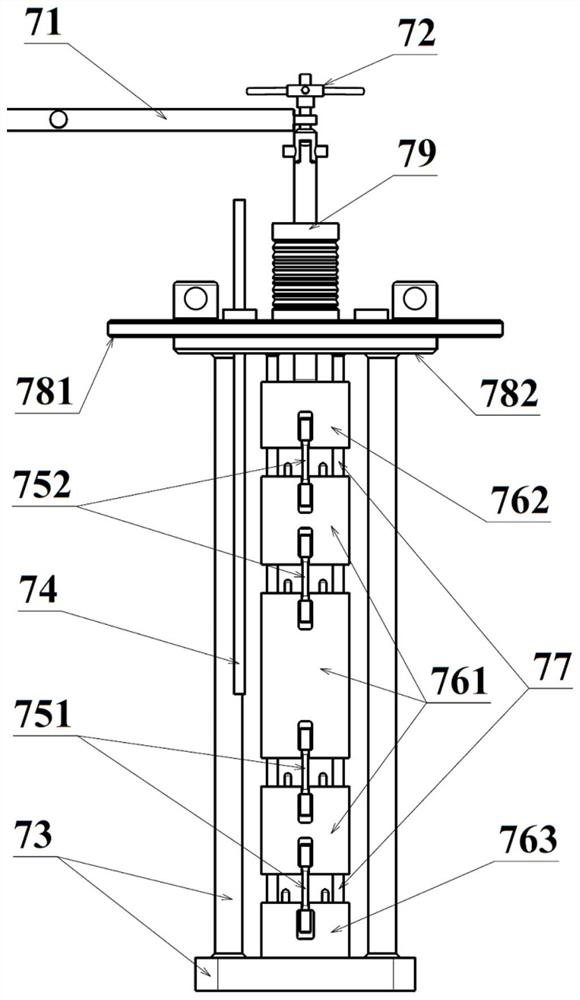

[0055] The liquid metal multi-specimen constant load stress corrosion test device functionally designs the liquid metal circuit system, loading system, vacuum / inflating system, temperature control / insulation system and the test bench for installation, and the specific composition and structure are described as follows:

[0056] Melting tank 1 outlet and experimental tank 2 outlet between the installation of liquid pipeline 6, installed on the liquid pipeline 6 from the experimental tank 2 outlet to the direction of the melting tank 1, successively installed with a cooler 5 and a liquid metal valve 3; and on the liquid pipeline 6 between the above cooler 5 and the liquid metal valve 3, there is a branch pipe connected to the entrance of the lower part of the experimental tank 2, the branch pipe is installed on the heater 4 and the pipeline heating cable 13;

[0057] Wherein, the branch c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com