Phosphorus-doped carbon dot photocatalytic material based on fly ash as well as preparation method and application of phosphorus-doped carbon dot photocatalytic material

A technology of photocatalytic materials and fly ash, which is applied in the field of photocatalytic materials, can solve the problems of inefficient utilization of metal elements, complicated preparation methods, and high costs, and achieve remarkable photocatalytic effects, high recycling rates, and stable properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

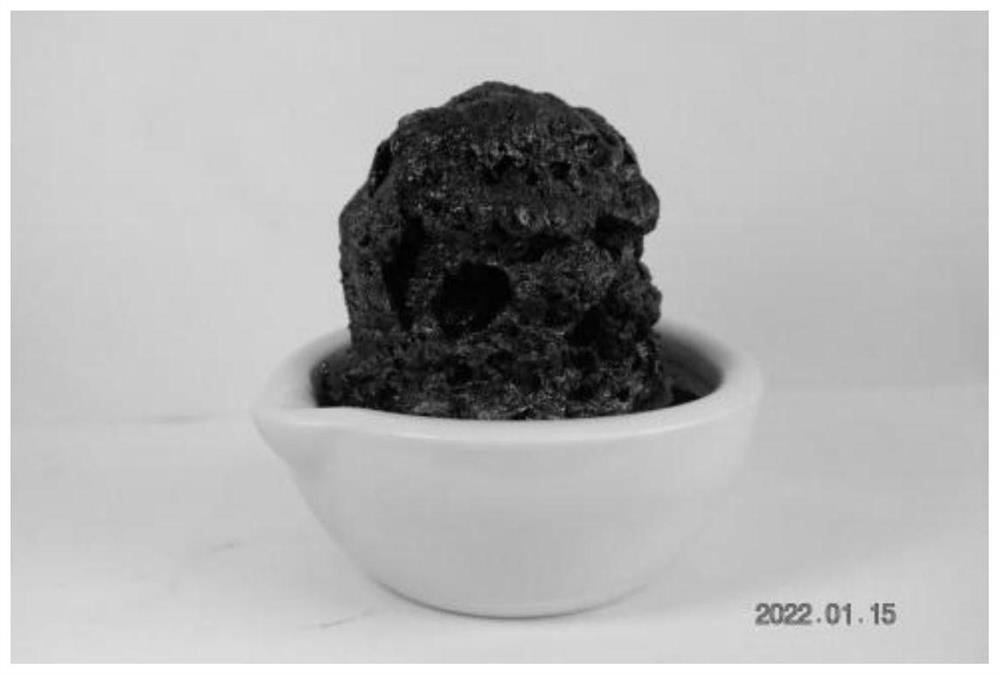

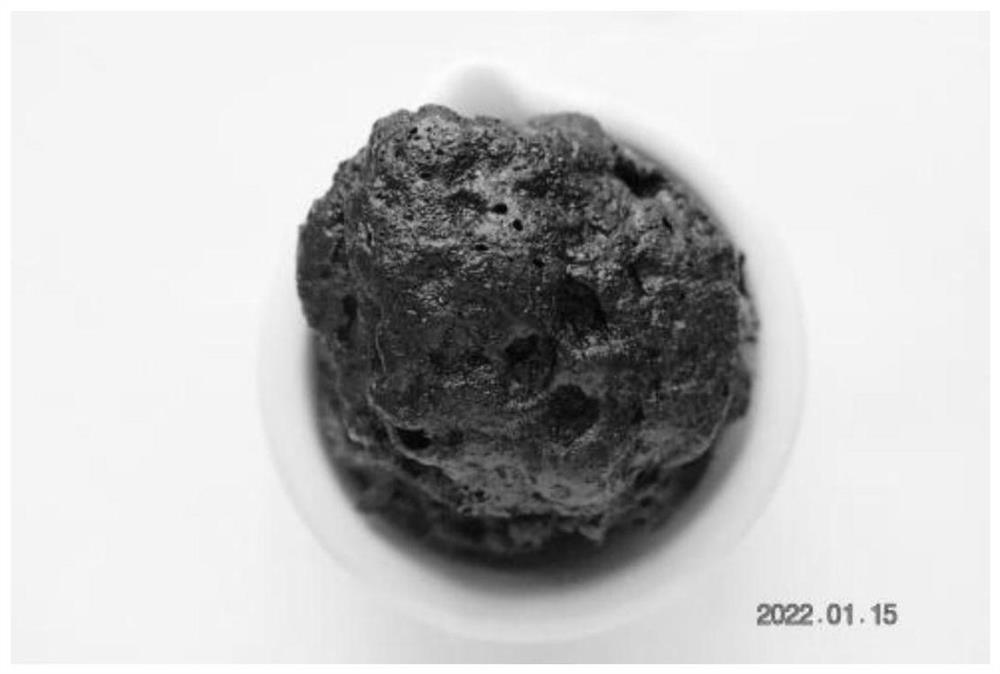

[0023] This example provides a method for preparing a phosphorus-doped carbon dot photocatalytic material based on fly ash. The specific steps are as follows: 5.0 g of sucrose is added to 10 ml of ultrapure water for ultrasonic dissolution for 10 minutes, and 2 ml of phosphoric acid (density of 1.874 g / mL) is added. After mixing, add 2g of fly ash and stir thoroughly, ultrasonic again for 10min, microwave (microwave power 700W) treatment for 4min (during the microwave process, about 1.5min, the reaction solution is burned dry, the material begins to expand, hydrogen gas is generated inside, and a micro-explosion is formed. , sparks splashed, producing a large number of pores, which grow layer by layer, forming a porous mushroom cloud-like material, such as figure 1 and figure 2 shown), after cooling to room temperature, mash and grind, wash, centrifuge, and dry at 60°C for 9 hours to obtain the final phosphorus-doped carbon dot photocatalytic material, which has a very large...

Embodiment 2

[0025] This example provides a method for preparing a phosphorus-doped carbon dot photocatalytic material based on fly ash. The only difference from Example 1 is that the masses of sucrose, phosphoric acid and fly ash are 7g, 5g and 2g respectively, and the remaining steps and The parameters are all the same.

experiment example 1

[0031] In this example, 50mg of rhodamine B was weighed and added to 50ml of ultrapure water for ultrasonic dissolution for 10min. Into 25mL of diluted rhodamine B solution, carry out dark reaction and light reaction for 2 hours respectively; measure the absorbance, calculate the degradation rate of rhodamine B, and the results are shown in Table 1.

[0032] Table 1

[0033] Numbering Degradation rate(%) Example 1 99% Example 2 98.5% Comparative example 1 75% Comparative example 2 35%

[0034] On the basis of the above experimental steps, rhodamine B was adjusted to methylene blue for experimentation, and the degradation rate of methylene blue was finally measured as shown in Table 2.

[0035] Table 2

[0036] Numbering Degradation rate(%) Example 1 99% Example 2 98.8% Comparative example 1 68% Comparative example 2 41%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com