Landfill leachate treatment system and treatment method thereof

A technology of landfill leachate and a treatment method, which is applied in landfill leachate treatment system and its treatment field, can solve problems such as pollution and threats to the health of surrounding people, and achieves reduction of secondary pollution, easy management and maintenance, and improved treatment efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

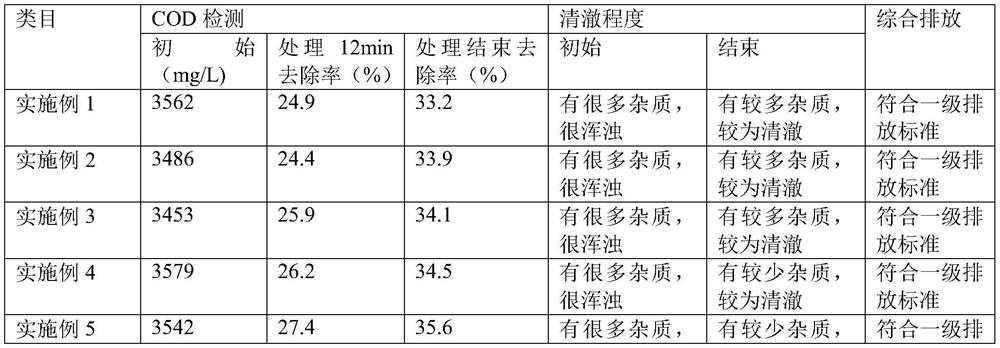

Examples

Embodiment 1

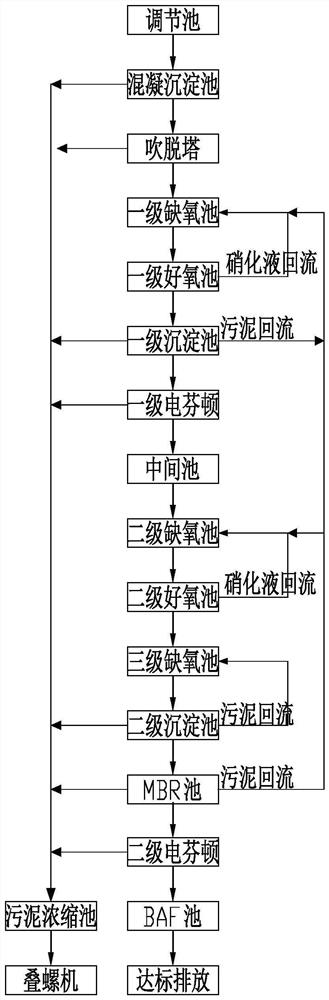

[0063] A landfill leachate treatment system, with reference to figure 1 , according to the treatment sequence of leachate, it includes pretreatment unit, biochemical oxidation unit, advanced oxidation unit and full quantitative treatment unit. The discharge of leachate is irregular, and the water quality is also significantly different. Therefore, before the leachate enters the treatment system, it flows into the adjustment tank first, and in the adjustment tank, it undergoes residence, deflection, aeration and mixing to stabilize the water volume and water quality of the leachate. state.

[0064] The pretreatment unit includes a coagulation sedimentation tank and a stripping tower which are connected by pipelines in turn. The water outlet is connected to the advanced oxidation unit. By adding a composite flocculant into the coagulation sedimentation tank, the particles that are difficult to settle in the water are aggregated to form colloids, and then combined with impuriti...

Embodiment 2-5

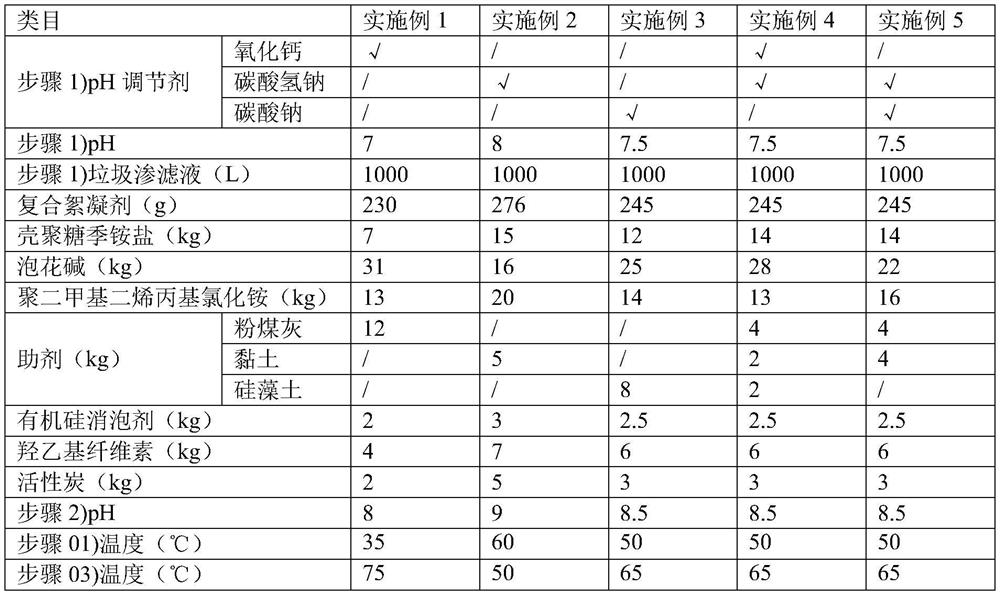

[0102] A landfill leachate treatment method, the difference from Example 1 is that in step 1),

[0103] The amount of input of chitosan quaternary ammonium salt, natron, polydimethyldiallyl ammonium chloride, silicone defoamer, hydroxyethyl cellulose, and activated carbon is different;

[0104] The choice and amount of additives are different;

[0105] The pH is different, and the choice of pH regulator is different.

[0106] In step 2), the pH is different;

[0107] Step 01) and step 03) have different temperatures.

[0108] The specific parameters are shown in Table 2.

[0109] Table 2

[0110]

Embodiment 6

[0112] A landfill leachate treatment method, the difference from Example 5 is that the auxiliary agent is that fly ash and diatomaceous earth are mixed in a ratio of 1:0.5 by weight, that is, the input amount of fly ash is 5.33kg, The input amount of diatomaceous earth is 2.67kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com