Reinforced modifier for concrete admixture and preparation method thereof

A technology of admixtures and modifiers, which is applied in the field of building materials to achieve the effect of realizing the activity of admixtures, improving surface activity, and improving cementing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

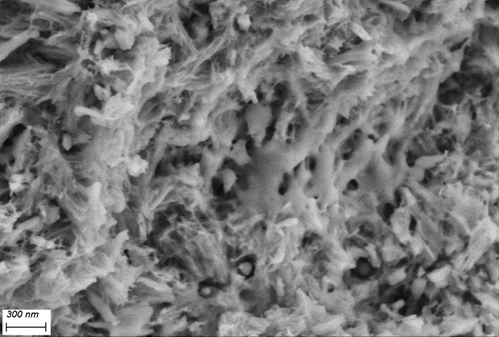

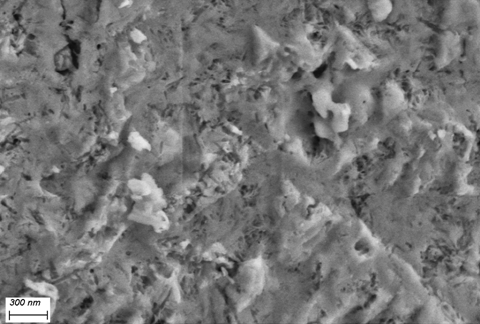

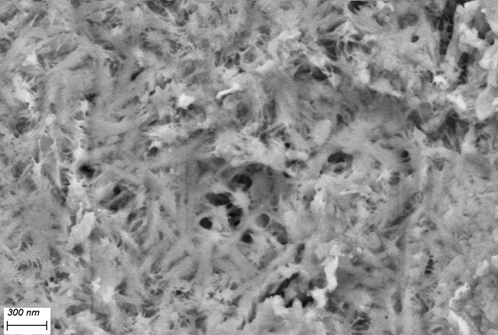

Image

Examples

Embodiment 1

[0032] In the first step, 15 parts of acrylic acid, 30 parts of acrylamide, 30 parts of acryl alcohol and 1 part of ferrous sulfate are dissolved in 240 parts of water, stirred evenly in the reactor, and heated to 60°C to obtain the base liquid.

[0033] In the second step, take 10 parts of ADDS, 0.2 parts of mercaptoethanol, 1 part of ammonium persulfate, and 50 parts of water, stir and mix them, and use a ultrasonic emulsifier to emulsify, and obtain A emulsion after emulsification. Keep the phacoemulsifier working throughout the production to maintain the emulsified state.

[0034] The third step is to drop liquid A into the base liquid into the reactor at a constant speed within 120 minutes. During this period, keep the ultrasonic emulsifier working, keep stirring in the reactor, and keep the temperature in the reactor not lower than 60°C and not higher than 75°C. ℃.

[0035]The fourth step, after the dropwise addition is completed, continue to stir until there is no more...

Embodiment 2

[0038] In the first step, 15 parts of acrylic acid, 35 parts of acrylamide, 30 parts of acryl alcohol and 1 part of ferrous sulfate are dissolved in 240 parts of water, stirred evenly in the reactor, and heated to 60°C to obtain the base liquid.

[0039] In the second step, take 5 parts of ADDS, 0.2 parts of mercaptoethanol, 1 part of ammonium persulfate, and 50 parts of water, stir and mix them, and use a ultrasonic emulsifier to emulsify to obtain A emulsion after emulsification. Keep the phacoemulsifier working throughout the production to maintain the emulsified state.

[0040] The third step is to drop liquid A into the base liquid into the reactor at a constant speed within 120 minutes. During this period, keep the ultrasonic emulsifier working, keep stirring in the reactor, and keep the temperature in the reactor not lower than 60°C and not higher than 75°C. ℃.

[0041] The fourth step, after the dropwise addition is completed, continue to stir until there is no more m...

Embodiment 3

[0044] In the first step, 15 parts of acrylic acid, 30 parts of acrylamide, 35 parts of acryl alcohol and 1 part of ferrous sulfate are dissolved in 240 parts of water, stirred evenly in the reactor, and heated to 60°C to obtain the base liquid.

[0045] In the second step, take 15 parts of ADDS, 0.2 parts of mercaptoethanol, 1 part of ammonium persulfate, and 50 parts of water, stir and mix them, and use a ultrasonic emulsifier to emulsify, and obtain A emulsion after emulsification. Keep the phacoemulsifier working throughout the production to maintain the emulsified state.

[0046] The third step is to drop liquid A into the base liquid into the reactor at a constant speed within 120 minutes. During this period, keep the ultrasonic emulsifier working, keep stirring in the reactor, and keep the temperature in the reactor not lower than 60°C and not higher than 75°C. ℃.

[0047] The fourth step, after the dropwise addition is completed, continue to stir until there is no mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com