Environment-friendly antibacterial foreign language translation machine material and preparation method thereof

A translation machine and foreign language technology, which is applied in the field of functional environmental protection materials and their preparation, can solve problems such as endangering the health of users, polluting groundwater sources, and producing harmful gases, so as to reduce energy consumption, reduce requirements, and enhance interface bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

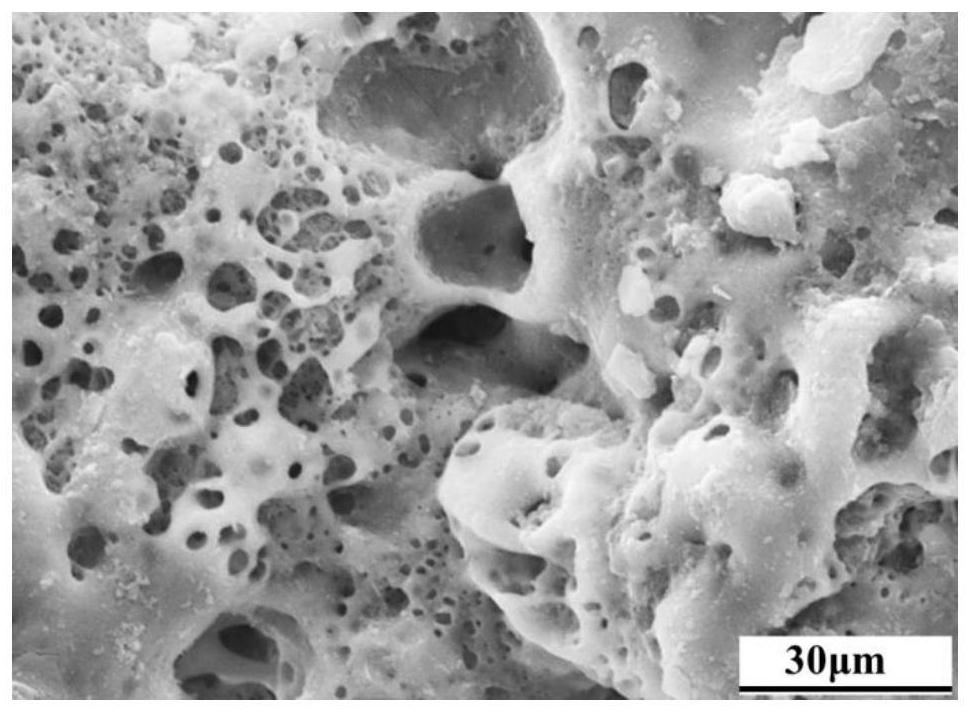

Image

Examples

Embodiment 1

[0033] (1) Dissolve chitosan in the mixed aqueous solution of 4wt.% acetic acid / 1wt.% ethylenediamine and stir, then add 0.2g / L dilute silver nitrate solution and stir, and use visible light irradiation to assist the electrostatic spinning process. The silk aperture is 0.1mm, and the voltage is 15kV. During the spinning process, visible light irradiation promotes Ag + In-situ reduction to nano-Ag to obtain chitosan antibacterial fibers loaded with nano-Ag particles;

[0034] (2) The biodegradable polylactic acid is heated to 180°C for melting, and the hollow filament is extruded through an extrusion molding process;

[0035] (3) Import the three-dimensional model of the foreign language translator into the fused deposition modeling machine, and perform layered slice processing;

[0036] (4) Put the chitosan antibacterial fiber loaded with nano-Ag particles described in step (1) into the hollow polylactic acid wire hole described in step (2), and send the wire to the After en...

Embodiment 2

[0040] (1) Dissolve chitosan in a mixed aqueous solution of 3.5wt.% acetic acid / 0.5wt.% ethylenediamine and stir, then add 0.8g / L dilute silver nitrate solution and stir, and use visible light irradiation to assist the electrospinning process , the spinning aperture is 0.2mm, and the voltage is 16kV. During the spinning process, visible light irradiation promotes Ag +In-situ reduction to nano-Ag to obtain chitosan antibacterial fibers loaded with nano-Ag particles;

[0041] (2) The biodegradable polylactic acid is heated to 180°C for melting, and the hollow filament is extruded through an extrusion molding process;

[0042] (3) Import the three-dimensional model of the foreign language translator into the fused deposition modeling machine, and perform layered slice processing;

[0043] (4) Put the chitosan antibacterial fiber loaded with nano-Ag particles described in step (1) into the hollow polylactic acid wire hole described in step (2), and send the wire to the After ent...

Embodiment 3

[0046] (1) Dissolve chitosan in a mixed aqueous solution of 3.5wt.% acetic acid / 0.5wt.% ethylenediamine and stir, then add 0.8g / L dilute silver nitrate solution and stir, and use visible light irradiation to assist the electrospinning process , the spinning aperture is 0.2mm, and the voltage is 18kV. During the spinning process, visible light irradiation promotes Ag + In-situ reduction to nano-Ag to obtain chitosan antibacterial fibers loaded with nano-Ag particles;

[0047] (2) The biodegradable polylactic acid is heated to 190°C for melting, and the hollow filament is extruded through an extrusion molding process;

[0048] (3) Import the three-dimensional model of the foreign language translator into the fused deposition modeling machine, and perform layered slice processing;

[0049] (4) Put the chitosan antibacterial fiber loaded with nano-Ag particles described in step (1) into the hollow polylactic acid wire hole described in step (2), and send the wire to the After en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com