6-series aluminum medium-temperature ultrasonic cleaning agent and preparation method thereof

An ultrasonic and cleaning agent technology, applied in the field of cleaning agents, can solve problems such as excessive degreasing, 6-series aluminum corrosion, and easy delamination, and achieve the effects of reducing interfacial tension, good cleaning ability, and improving detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

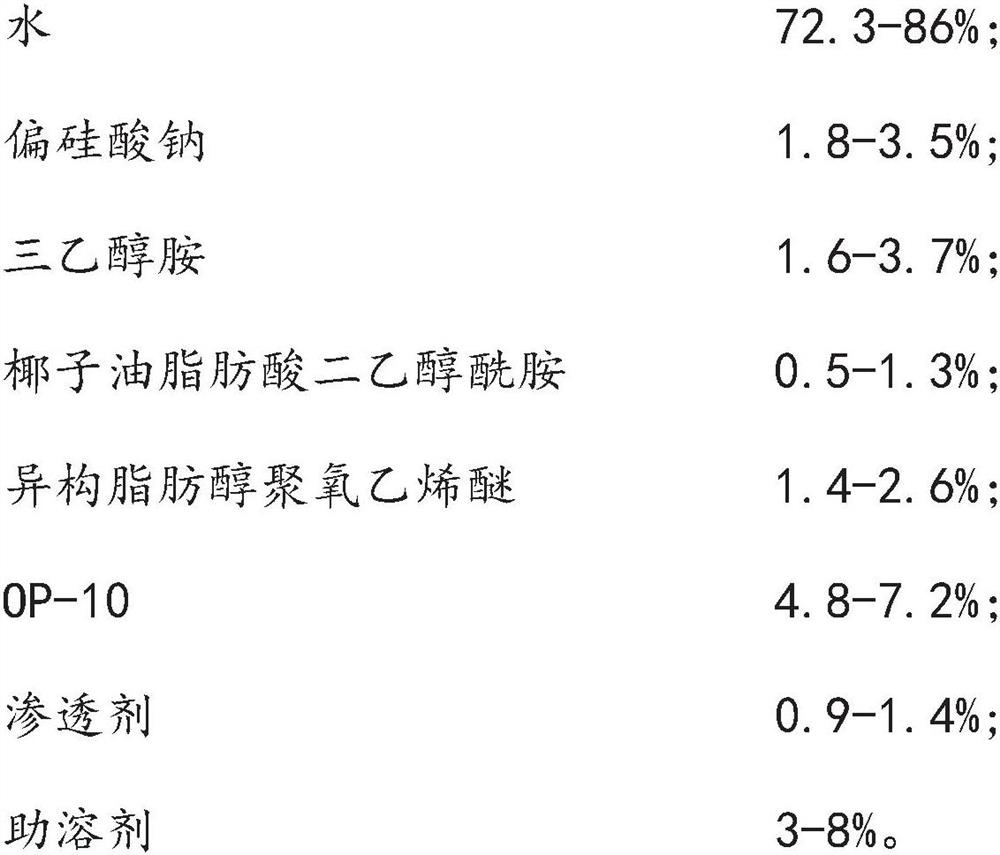

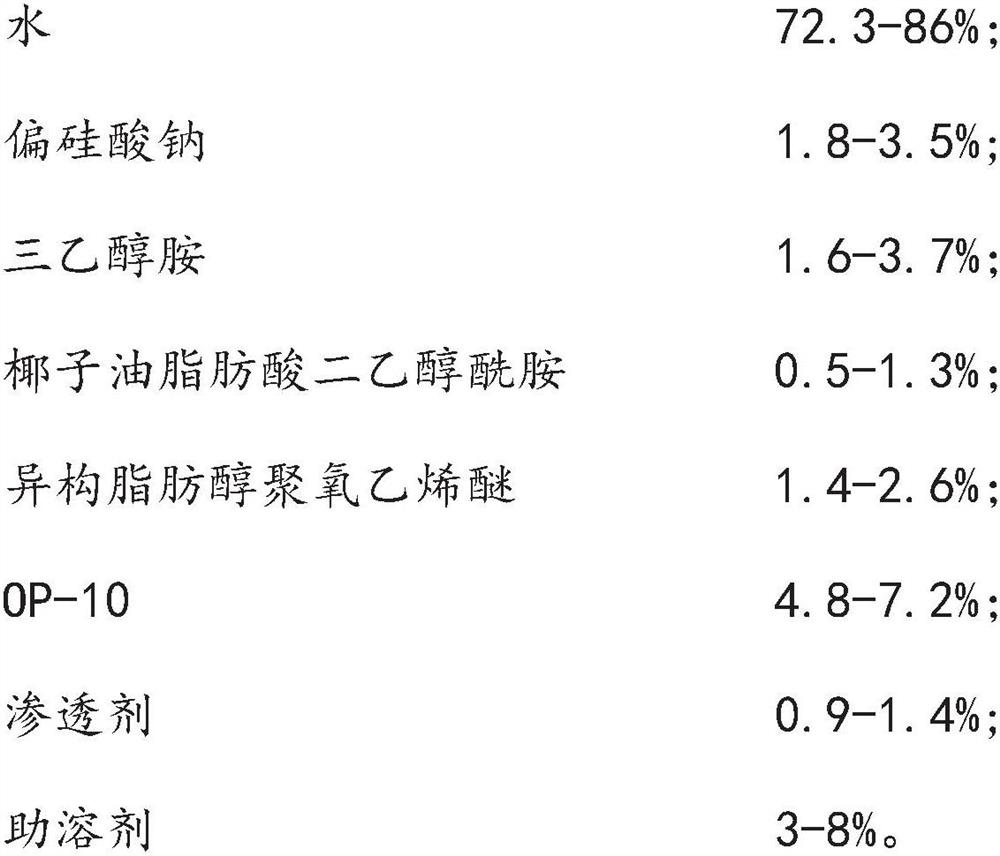

[0028] The preparation material of the cleaning agent comprising the following components in weight percent: 72.3-86% of water, 1.8-3.5% of sodium metasilicate, 1.6-3.7% of triethanolamine, 0.5-1.3% of coconut oil fatty acid diethanolamide, isomerized fat Alcohol polyoxyethylene ether 1.4-2.6%, OP-10 4.8-7.2%, penetrant 0.9-1.4%, co-solvent 3-8%.

[0029] Add part of water and sodium metasilicate into a clean container, stir and dissolve at low speed, then add triethanolamine; after stirring continuously for a period of time, add the remaining water, coconut oil fatty acid diethanolamide, isomeric fatty alcohol polyoxyethylene ether, OP- 10. For the penetrant and co-solvent, stir evenly at a low speed until the liquid is transparent and colorless to obtain a cleaning agent. The finished product of the cleaning agent is a transparent, colorless and homogeneous liquid, which does not delaminate at low temperature (5°C) or high temperature (50°C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com