Flame-retardant and anti-aging cover plate for spare tire of car trunk and preparation method of flame-retardant and anti-aging cover plate

A suitcase and anti-aging technology, applied in chemical instruments and methods, spare tire layout, vehicle parts, etc., can solve the problems of poor flame retardancy, low strength, and unsatisfactory load-bearing performance for practical applications, so as to improve compatibility, Improved aging resistance and improved UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

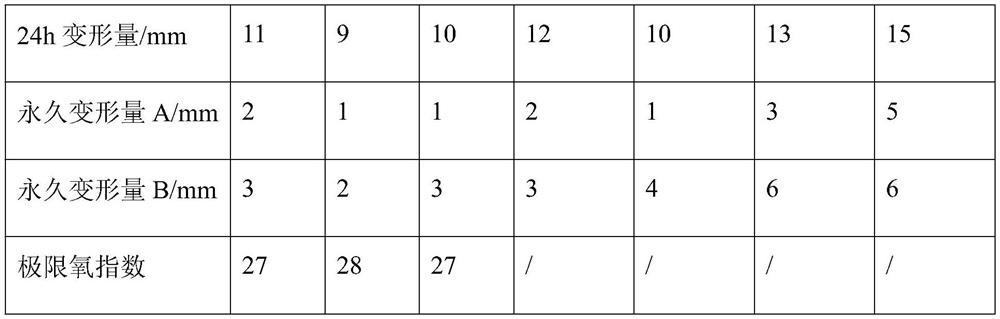

example 1

[0028] A method for preparing a flame-retardant and aging-resistant cover plate for a spare tire of an automobile trunk, comprising the following steps:

[0029] (1) Dissolve 0.6g of graphene oxide and deionized water, ultrasonically disperse for 20min, add ammonia water to adjust the pH to 11, then add 6mL of triethylenetetramine, stir and react in an oil bath at 90°C for 10h, and collect the product by suction filtration. Washing by ethanol and deionized water successively, and drying in vacuum to obtain aminated graphene;

[0030] Mix pentaerythritol and phosphorus oxychloride evenly, stir and react at 70°C for 9 hours, wash with chloroform, collect the product by suction filtration, and dry in vacuum to obtain a flame retardant intermediate; the molar ratio of pentaerythritol and phosphorus oxychloride is 1:2.

[0031] Take p-hydroxybenzaldehyde, triethylamine and acetonitrile, mix and stir for 30 minutes to obtain solution A; the mass ratio of p-hydroxybenzaldehyde and tr...

example 2

[0037] A method for preparing a flame-retardant and aging-resistant cover plate for a spare tire of an automobile trunk, comprising the following steps:

[0038] (1) Dissolve 0.6g of graphene oxide and deionized water, ultrasonically disperse for 25min, add ammonia water to adjust the pH to 11, then add 6mL of triethylenetetramine, stir and react for 9h in an oil bath at 95°C, and collect the product by suction filtration. Washing by ethanol and deionized water successively, and drying in vacuum to obtain aminated graphene;

[0039] Mix pentaerythritol and phosphorus oxychloride evenly, stir and react at 75°C for 8.5 hours, wash with chloroform, collect the product by suction filtration, and dry in vacuum to obtain a flame retardant intermediate; the molar ratio of pentaerythritol and phosphorus oxychloride is 1:2 .

[0040] Take p-hydroxybenzaldehyde, triethylamine and acetonitrile, mix and stir for 35 minutes to obtain solution A; the mass ratio of p-hydroxybenzaldehyde and...

example 3

[0046] A method for preparing a flame-retardant and aging-resistant cover plate for a spare tire of an automobile trunk, comprising the following steps:

[0047] (1) Dissolve 0.6 g of graphene oxide and deionized water, ultrasonically disperse for 30 min, add ammonia water to adjust the pH to 11, then add 6 mL of triethylenetetramine, stir and react in an oil bath at 95 °C for 8 h, and collect the product by suction filtration. Washing by ethanol and deionized water successively, and drying in vacuum to obtain aminated graphene;

[0048] Mix pentaerythritol and phosphorus oxychloride evenly, stir and react at 80°C for 8 hours, wash with chloroform, collect the product by suction filtration, and dry in vacuum to obtain a flame retardant intermediate; the molar ratio of pentaerythritol and phosphorus oxychloride is 1:2.

[0049] Take p-hydroxybenzaldehyde, triethylamine and acetonitrile, mix and stir for 40 minutes to obtain solution A; the mass ratio of p-hydroxybenzaldehyde an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com