Microbial adsorbent for industrial wastewater and preparation method thereof

A technology for microbial adsorption and industrial wastewater, applied in water pollutants, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as poor wastewater treatment effect, achieve stable and long-lasting wastewater treatment capacity, good dispersion, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for a microbial adsorbent for industrial wastewater, comprising the steps of:

[0030] (1) 1gFe 3 o 4 Nanoparticles and 5g of aminopropyltriethoxysilane were added to a mixed solvent of 50mL of methanol and 50mL of toluene, mixed evenly, and refluxed in an oil bath at 100°C for 10 hours. After the reaction, the refluxed product was washed with methanol for 3 times , and carry out vacuum suction filtration on the obtained cleaning product, after the suction filtration is completed, place the suction filtration product in a vacuum drying oven to dry, and after drying, grind it into powder to obtain amino-modified ferric oxide;

[0031] (2) 8g chitosan is added to 100mL, in 10wt% acetic acid solution, stirring and dissolving, then adding 5g amino-modified ferric oxide and 3g cross-linking agent genipin to it, at 45 ℃, 400r / min Heating and stirring for 2 hours, after the reaction was finished, ferric oxide modified chitosan was obtained;

[0032] (3)...

Embodiment 2

[0037] A preparation method for a microbial adsorbent for industrial wastewater, comprising the steps of:

[0038] (1) Add 2gFe 3 o 4 Nanoparticles and 8g of aminopropyltriethoxysilane were added to a mixed solvent of 50mL of methanol and 50mL of toluene, mixed evenly, and refluxed in an oil bath at 100°C for 10h. After the reaction, the refluxed product was washed with methanol for 3 times , and carry out vacuum suction filtration on the obtained cleaning product, after the suction filtration is completed, place the suction filtration product in a vacuum drying oven for drying, and grind it into powder after drying to obtain amino-modified ferric oxide;

[0039] (2) 10g of chitosan is added to 100mL, in 10wt% acetic acid solution, stirred and dissolved, then 8g of amino-modified ferric oxide and 4g of cross-linking agent genipin are added thereto, at 45°C, 400r / min Heating and stirring for 2 hours, after the reaction was finished, ferric oxide modified chitosan was obtained...

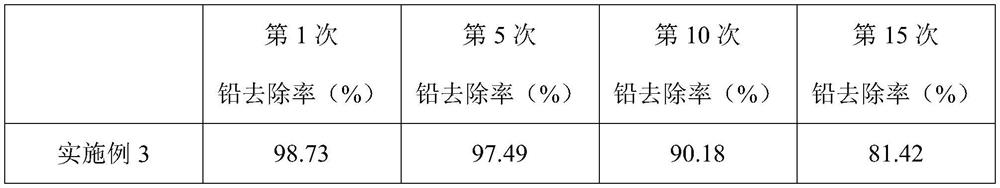

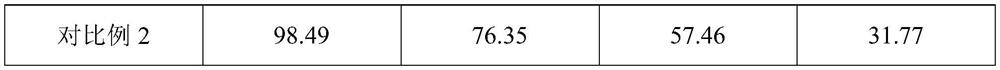

Embodiment 3

[0045] A preparation method for a microbial adsorbent for industrial wastewater, comprising the steps of:

[0046] (1) Add 2gFe 3 o 4 Nanoparticles and 10g of aminopropyltriethoxysilane were added to a mixed solvent of 50mL of methanol and 50mL of toluene, mixed evenly, and refluxed in an oil bath at 120°C for 8 hours. After the reaction, the refluxed product was washed with methanol for 3 times , and carry out vacuum suction filtration on the obtained cleaning product, after the suction filtration is completed, place the suction filtration product in a vacuum drying oven for drying, and grind it into powder after drying to obtain amino-modified ferric oxide;

[0047] (2) 10g of chitosan is added to 100mL, in 10wt% acetic acid solution, stirred and dissolved, then 6g of amino-modified ferric oxide and 5g of cross-linking agent genipin are added thereto, at 45°C, 400r / min Heating and stirring for 2 hours, after the reaction was finished, ferric oxide modified chitosan was obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com