Preparation method of heat insulation tile with complex shape for combustion chamber of gas turbine

A complex-shaped, gas turbine technology is applied in the field of preparing complex-shaped heat-insulating tiles for gas turbine combustion chambers, and can solve the problems of long curing time, low green strength, and complex curing process, and achieve easy demoulding and blank processing. , the effect of improving thermal shock stability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

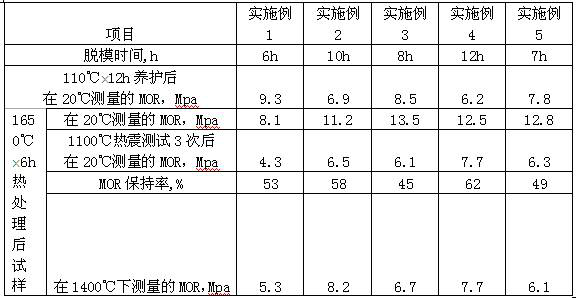

Examples

Embodiment 1

[0028] A method for preparing heat-insulating tiles with complex shapes for combustion chambers of gas turbines. The composition and weight parts of the heat-insulating tile castables are: 45 parts of corundum aggregate, 30 parts of mullite aggregate, and 10 parts of mullite fine powder , 10 parts of corundum fine powder, 5 parts of alumina fine powder, plus: 0.15 parts of solid dispersant FS20, 4.5 parts of binder silica sol solution, 3 parts of water, 0.05 parts of solid aluminum formate flocculant (or curing agent ); dry mix the solid raw materials together for 2 minutes, then add the silica sol solution and water and mix in a blender for 2 to 5 minutes, pour into the mold, maintain at room temperature for 12 hours, demould, and bake at 110°C After drying, it was kept at 1650°C for 6 hours.

Embodiment 2

[0030] A method for preparing heat-insulating tiles with complex shapes for combustion chambers of gas turbines. The composition and weight parts of the heat-insulating tile castables are: 35 parts of corundum aggregate, 35 parts of mullite aggregate, and 5 parts of mullite fine powder , 15 parts of corundum fine powder, 10 parts of alumina fine powder, plus: 0.2 parts of solid dispersant FS20, 3.5 parts of binder silica sol solution, 3.5 parts of water, 0.03 parts of solid aluminum formate flocculant (or curing agent ); dry mix the solid raw materials together for 2 minutes, then add the silica sol solution and water and mix in a blender for 2 to 5 minutes, pour into the mold, maintain at room temperature for 12 hours, demould, and bake at 110°C After drying, it was kept at 1650°C for 6 hours.

Embodiment 3

[0032] A method for preparing heat-insulating tiles with complex shapes for combustion chambers of gas turbines. The composition and weight parts of the heat-insulating tile castables are: 30 parts of corundum aggregate, 30 parts of mullite aggregate, and 10 parts of mullite fine powder , 15 parts of corundum fine powder, 15 parts of alumina fine powder, plus: 0.2 parts of solid dispersant FS20, 4 parts of binder silica sol solution, 3 parts of water, 0.02 parts of solid aluminum formate flocculant (or curing agent ); dry mix the solid raw materials together for 2 minutes, then add the silica sol solution and water and mix in a blender for 2 to 5 minutes, pour into the mold, maintain at room temperature for 12 hours, demould, and bake at 110°C After drying, it was kept at 1650°C for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com