Polytetrafluoroethylene modified filler, modified polytetrafluoroethylene composite material, preparation method and application

A polytetrafluoroethylene and composite material technology, applied in the field of modified polytetrafluoroethylene composite materials and preparation, polytetrafluoroethylene modified filler, can solve the interface difference, friction coefficient and wear rate can not be reduced at the same time, filler and The problem of matrix interface has not been effectively solved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

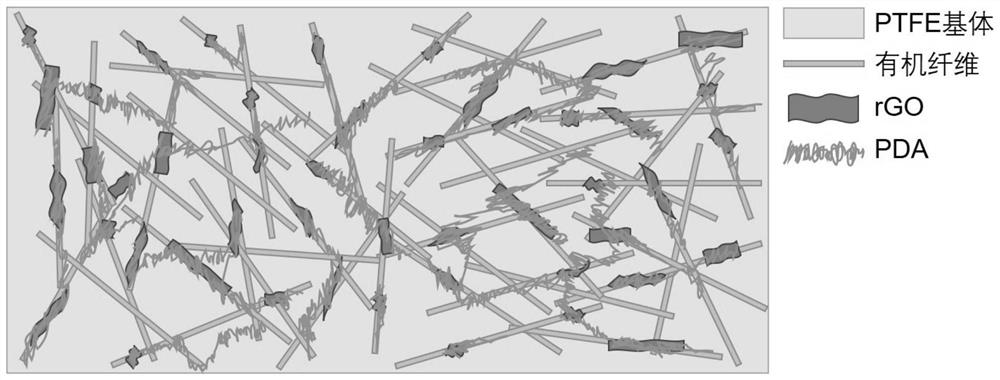

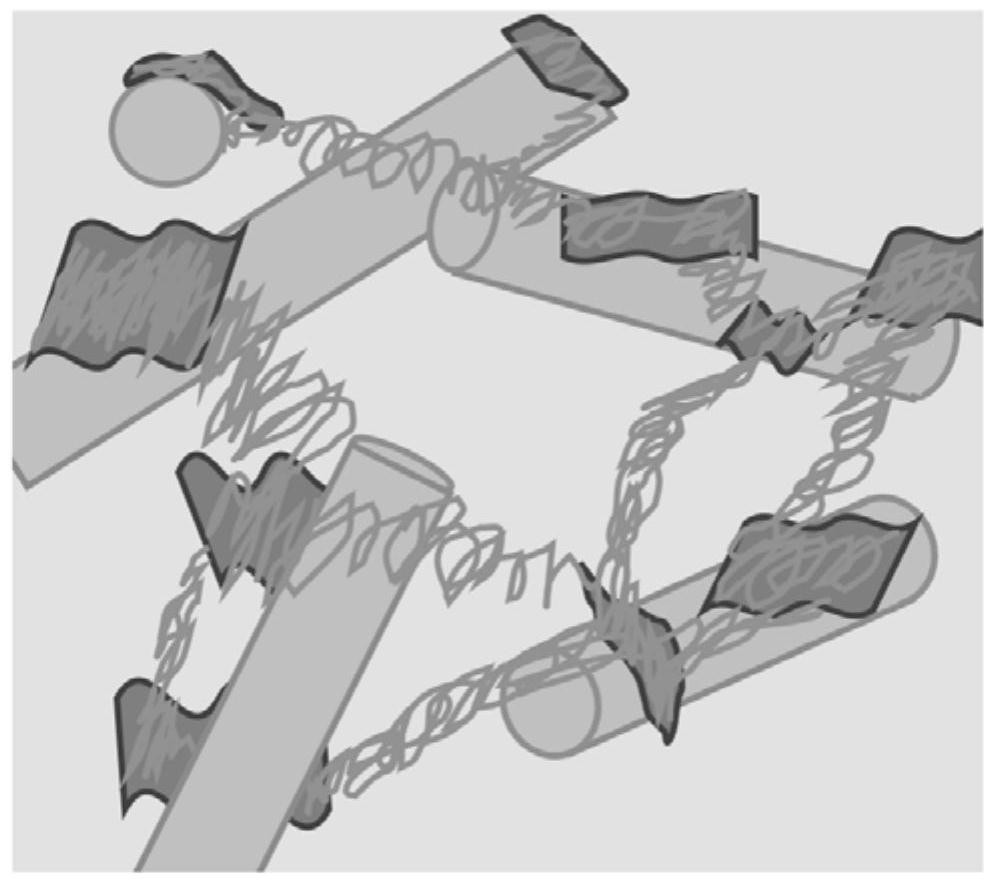

[0044] In some embodiments, the preparation method of the polytetrafluoroethylene modified filler includes: mixing organic fibers, graphene oxide nanosheets, dopamine hydrochloride, Tris-HCl buffer solution and a solvent. The solvent can be water and / or conventional organic solvents such as methanol, ethanol, acetone, and the like.

[0045] In some embodiments, the preparation method of polytetrafluoroethylene modified filler includes:

[0046]S1, mixing graphene oxide nanosheets, dopamine hydrochloride, Tris-HCl buffer solution and solvent, heating and reacting to obtain a solution containing polydopamine-graphene oxide nanosheets;

[0047] S2, immersing the organic fibers in a solution containing polydopamine-graphene oxide nanosheets.

[0048] The solvent in the preparation method is the same as the above-mentioned solvents, and can be water and / or conventional organic solvents, such as methanol, ethanol, acetone, and the like.

[0049] In some preferred embodiments, the ...

Embodiment 1~5 and comparative example 1~7

[0087] Prepare the modified polytetrafluoroethylene composite material according to the ratio of raw materials shown in Table 1, and the specific preparation method is as follows:

[0088] (1) Chopped polyimide fibers with a fiber density of 2.2dtex and a fiber length of 1 to 3 mm were ultrasonically cleaned with acetone and ethanol for 15 to 20 minutes, and then dried.

[0089] (2) A certain amount of graphene oxide nanosheets (with a sheet diameter of 1 μm to 50 μm) was placed in deionized water and stirred and mixed to prepare a graphene oxide nanosheet solution with a concentration of 10 mg / mL.

[0090] (3) Soak the treated polyimide fibers in the graphene oxide nanosheet solution, and stir for 20 minutes with magnetic force to mix.

[0091] (4) Take an appropriate amount of the mixed impregnating liquid of step (3), add dopamine hydrochloride to the mixed impregnating liquid, add Tris-HCl solution (trishydroxymethylaminomethane hydrochloride, commercially available, conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com