Oil-gas mixed transportation system

A mixed transportation and oil-gas technology, applied in the charging system, turbine/propulsion fuel delivery system, liquid fuel engine, etc., can solve the problems affecting the safe, reliable and efficient operation of centrifugal aviation fuel pumps, and improve the oil-gas mixture. The effect of conveying capacity, reducing the speed of implication, and reducing the rate of cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

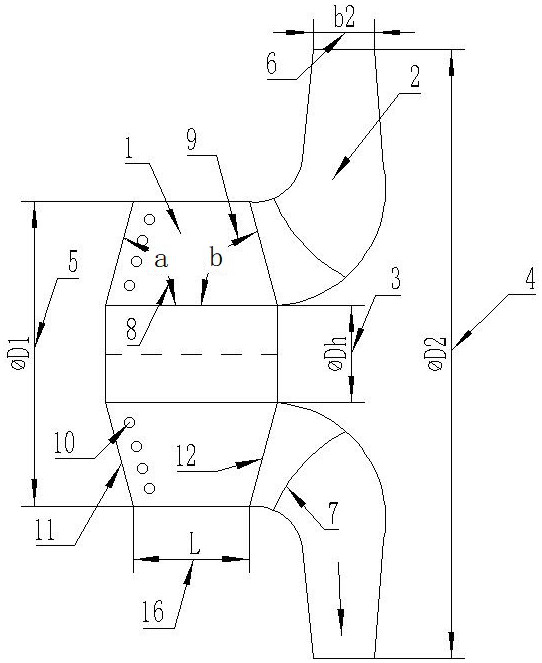

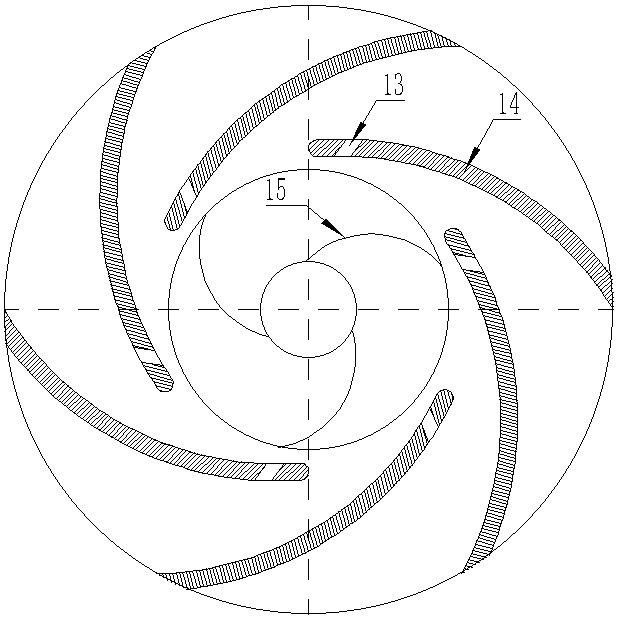

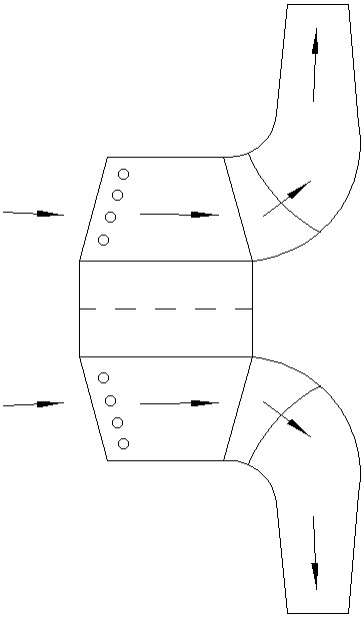

[0026] An oil-vapor mixed transmission system, such as Figure 1-Figure 3 As shown, it includes a pre-supercharged auxiliary impeller 1 and a cylindrical blade main impeller 2 arranged in sequence from front to back, and a spiral axial flow impeller with a variable pitch spiral structure is used as the pre-supercharged auxiliary impeller 1; the cylindrical blade main impeller 2 The head of the front supercharging sub-impeller is provided with a slot jet groove 13; the blade inlet edge 11 head of the pre-supercharging sub-impeller is rounded, and the blade head of the pre-supercharging sub-impeller 1 is provided with several cylindrical blade main impellers. The inlet side 7 of the vane is parallel to the exhaust hole 10; the impeller of the oil-gas mixed transmission system rotates clockwise, and the vapor phase is entrained by the liquid and enters the pre-pressurized auxiliary impeller 1, and enters the cylindrical blade main impeller under the action of lift 2. Enter the pr...

Embodiment 2

[0029] This embodiment is optimized on the basis of embodiment 1, such as figure 1 As shown, the blade inlet side 11 and outlet side 12 of the pre-supercharged auxiliary impeller form an included angle a8 and an included angle b9 with the hub 3 respectively, and the angles of the included angle a8 and the included angle b9 are 60° ~80°, which can ensure small impact on the inlet of the main impeller.

[0030] Further, as figure 1 As shown, the pitch-variable helix of the pre-supercharged auxiliary impeller 1 increases in pitch as the axial length 16 increases, and the wrap angle formed by the blades is 270°-300°. The variable-pitch helix has good cavitation resistance, and the equidistant helix is stronger in confining the fluid. When the blade wrap angle between 300 and 360 is used, the pressure changes drastically. The present invention proposes that the wrap angle of 270° to 300° can Reduce the situation where the pressure on the blade changes drastically when it is in ...

Embodiment 3

[0033] This embodiment is optimized on the basis of Embodiment 2. The inlet diameter and hub diameter of the pre-supercharged auxiliary impeller 1 and the cylindrical blade main impeller 2 are equal, and the blade outlet edge 12 of the pre-supercharged auxiliary impeller There is a gap with the inlet edge of the cylindrical blade main impeller 2 . The same diameter can ensure that there is no pressure drop between the pre-charged auxiliary impeller and the cylindrical blade main impeller, and the flow is smooth; the gap ensures the clearance fit between the two and the uniform flow state at the inlet of the cylindrical blade main impeller.

[0034] Further, as figure 1 As shown, the ratio of the inlet diameter 5 of the pre-supercharged auxiliary impeller to the outer diameter 4 of the cylindrical blade main impeller is less than or equal to 1; the ratio of the outer diameter 4 of the cylindrical blade main impeller to the outlet width 6 is less than or equal to 10. The presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com