Sulfide solid electrolyte layer, preparation method thereof and lithium ion battery

A solid electrolyte, sulfide technology, applied in the direction of electrolyte, electrolyte immobilization/gelation, secondary battery, etc., can solve the problems to be improved, limited solvent range, difficult to recycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

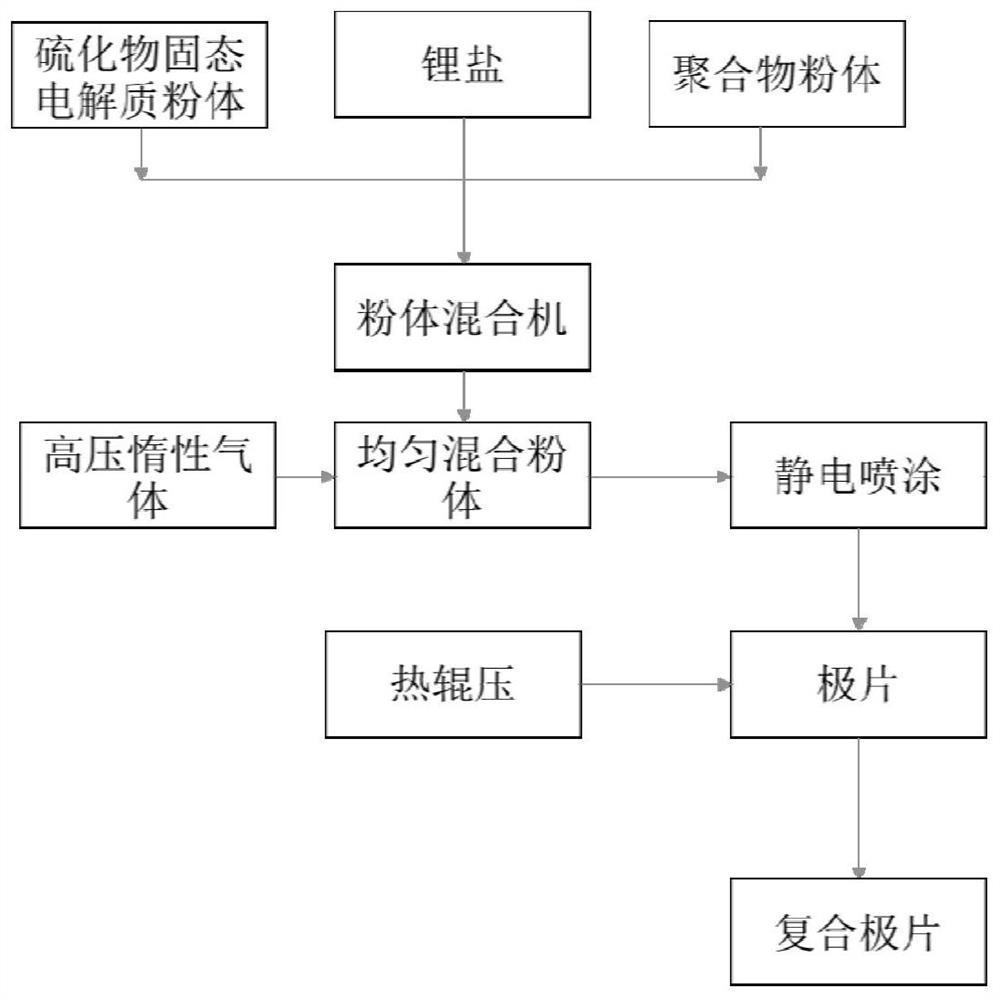

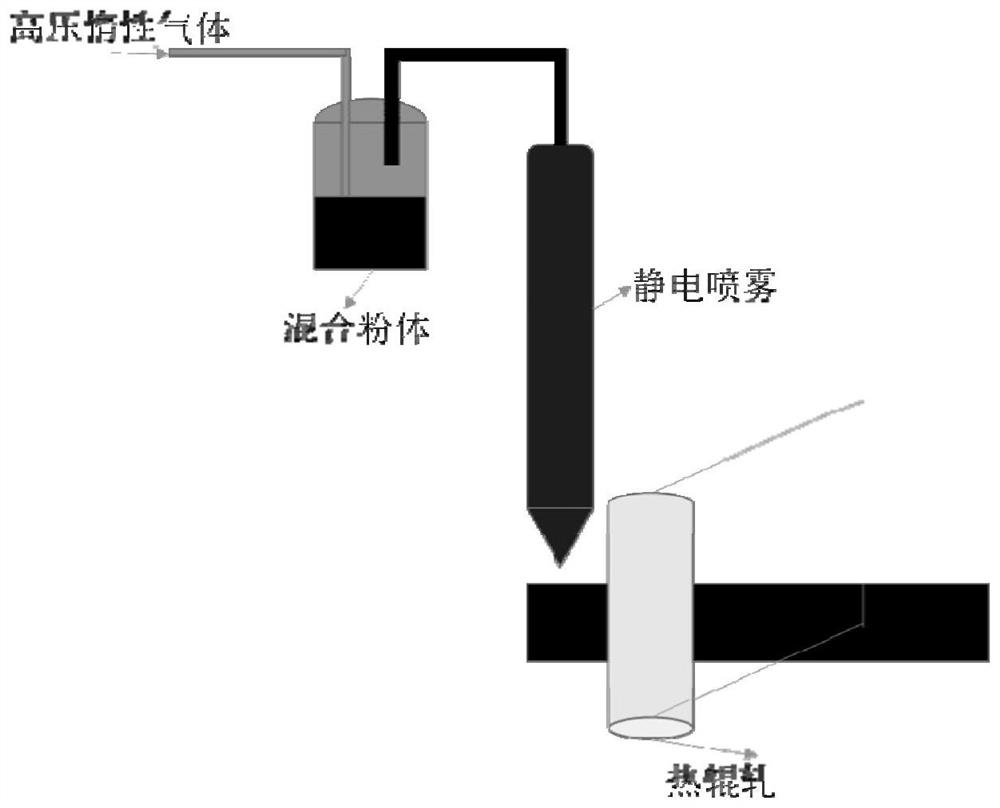

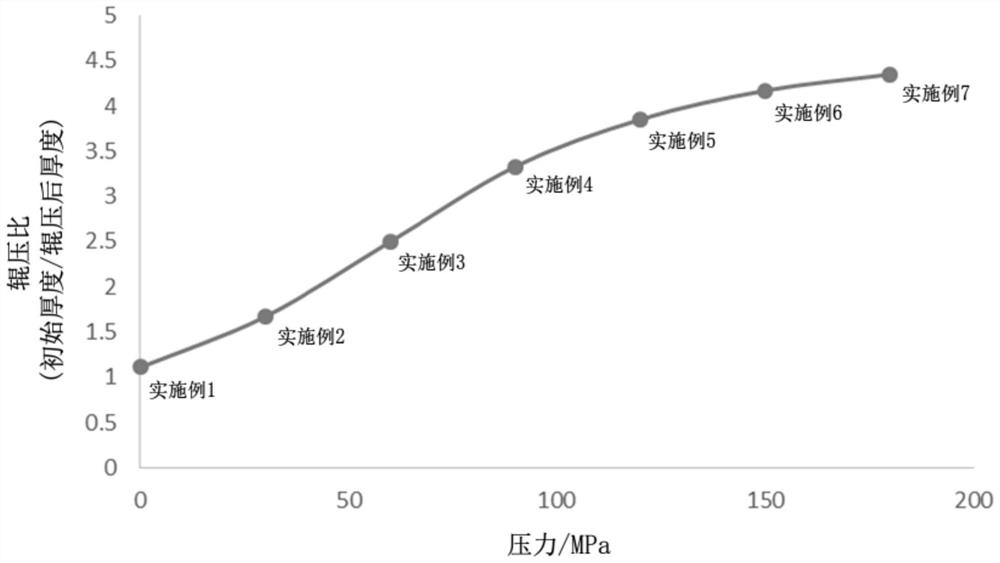

[0046] refer to figure 1 and 2 , the refined sulfide solid electrolyte Li with an average particle size of 1 μm 6 P.S. 5 Cl, lithium salt LiTFSI, and thermoplastic polymer powder polyvinylidene fluoride-hexafluoropropylene were mixed for 60 minutes according to the mass ratio of 10:1:1.1, dispersed to a suspended state by high-pressure argon, and sprayed onto the positive electrode sheet by electrostatic spray gun. Form the solid electrolyte primary coating, then set the roll temperature to 200°C, the rolling speed to 50cm / min, and roll the solid electrolyte primary coating under the condition of 0 rolling pressure to complete the preparation of the solid electrolyte layer. A composite pole piece formed with a sulfide solid electrolyte layer is obtained.

Embodiment 2

[0048] The refined sulfide solid electrolyte Li with an average particle size of 1 μm 6 P.S. 5 Cl, lithium salt LiTFSI, and thermoplastic polymer powder polyvinylidene fluoride-hexafluoropropylene were mixed for 60 minutes according to the mass ratio of 10:1:1.1, dispersed to a suspended state by high-pressure argon, and sprayed onto the positive electrode sheet by electrostatic spray gun. Form the solid electrolyte primary coating, then set the roll temperature to 200°C, the rolling speed to 50cm / min, and roll the solid electrolyte primary coating under the condition of a rolling pressure of 30MPa to complete the preparation of the solid electrolyte layer. A composite pole piece formed with a sulfide solid electrolyte layer is obtained.

Embodiment 3

[0050] The refined sulfide solid electrolyte Li with an average particle size of 1 μm 6 P.S. 5 Cl, lithium salt LiTFSI, and thermoplastic polymer powder polyvinylidene fluoride-hexafluoropropylene were mixed for 60 minutes according to the mass ratio of 10:1:1.1, dispersed to a suspended state by high-pressure argon, and sprayed onto the positive electrode sheet by electrostatic spray gun. Form the solid electrolyte primary coating, then set the roll temperature to 200°C, the rolling speed to 50cm / min, and roll the solid electrolyte primary coating under the condition of a rolling pressure of 60MPa to complete the preparation of the solid electrolyte layer. A composite pole piece formed with a sulfide solid electrolyte layer is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com