Preparation method of sugar-free sparkling water

A technology of sparkling water and sucralose, which is applied in the field of beverage processing, can solve the problems of low sweetness, inconspicuous flavor, bland and tasteless, etc., and achieves the effects of prolonging the shelf life, ensuring the taste and quality, and being cheap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

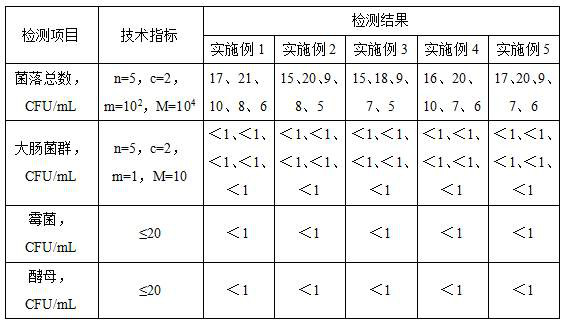

Examples

Embodiment 1

[0036] The application provides a method for preparing sugar-free sparkling water, which adopts the following technical scheme:

[0037] A preparation method of sugar-free sparkling water, specifically comprising the following steps:

[0038] S1, preparation nerve sweet essence:

[0039] S1.1. Select 38 parts by weight of dry stevia, 15 parts by weight of samara vine, 10 parts by weight of orange peel and 4 parts by weight of perilla as raw materials. According to the material-to-liquid ratio of 1:5, add water and heat up to 45°C, keep warm and add Sodium chloride and polysorbate 80, the mass ratio of control raw material, sodium chloride and polysorbate 80 is 80:11:1, filter after stirring treatment 1h, filter residue adds clear water to wash and dry, pulverizes to obtain particle diameter of 40 Purpose mixed powder;

[0040] S1.2. According to the material-to-liquid ratio of 1:17, add the mixed powder and diethyl ether into the ultrasonic extractor. After ultrasonic-assist...

Embodiment 2

[0045] The application provides a method for preparing sugar-free sparkling water, which adopts the following technical scheme:

[0046] A preparation method of sugar-free sparkling water, specifically comprising the following steps:

[0047] S1, preparation nerve sweet essence:

[0048] S1.1. Select 40 parts by weight of dry stevia, 18 parts by weight of samara vine, 15 parts by weight of orange peel and 5 parts by weight of perilla as raw materials. According to the material-to-liquid ratio of 1:6, add water to heat up to 50 ° C, keep warm and add Sodium chloride and polysorbate 80, control the mass ratio of raw material, sodium chloride and polysorbate 80 to be 85:12:1, filter after stirring treatment 1.5h, dry, pulverize after filter residue adds clear water to obtain particle diameter. 80 mesh mixed powder;

[0049] S1.2. According to the material-to-liquid ratio of 1:18, add the mixed powder and diethyl ether into the ultrasonic extractor, and extract the extract by ce...

Embodiment 3

[0054] The application provides a method for preparing sugar-free sparkling water, which adopts the following technical scheme:

[0055] A preparation method of sugar-free sparkling water, specifically comprising the following steps:

[0056] S1, preparation nerve sweet essence:

[0057] S1.1. Select 44 parts by weight of dry stevia, 20 parts by weight of samara vine, 20 parts by weight of orange peel and 6 parts by weight of perilla as raw materials. According to the material-to-liquid ratio of 1:8, add water to heat up to 55 ° C, keep warm and add Sodium chloride and polysorbate 80, control the mass ratio of raw materials, sodium chloride and polysorbate 80 to be 90:13:1, filter after stirring for 2 hours, dry and pulverize the filter residue after adding clear water to obtain a particle size of 120 Purpose mixed powder;

[0058] S1.2. According to the material-to-liquid ratio of 1:19, add the mixed powder and diethyl ether into the ultrasonic extractor, and extract the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com