Magnetic nanoparticles as well as preparation method and application thereof

A magnetic nanoparticle and nanoparticle technology, applied in the field of chemistry, can solve the problems of low adsorption capacity and long extraction time, and achieve the effects of strong adsorption capacity, short adsorption time and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] Specifically, according to an embodiment of the present invention, the shell material Fe 3 o 4 The synthetic method of @COF(PPD-TFPB) includes: In a 50mL two-necked round bottom flask, 100mg of Fe 3 o 4 and 116 mg of PPD were added to 22 mL of THF and sonicated for 20 min. Second, the mixture was mechanically stirred at 60–70°C for 20–40 min, so that part of the PPD was first uniformly anchored to Fe through hydrogen bonds 3 o 4 surface. Then, 60 mg of TFPB was uniformly dispersed in 8 mL of THF, and it and 1 mL of acetic acid were added dropwise to the above reaction system under stirring. After the addition was completed, the reaction was carried out for 2-3 hours to obtain imine covalent Organic framework coated magnetic Fe 3 o 4 .

[0077] Further, according to yet another aspect of the present invention, the present invention provides a method for adsorbing biological toxins. According to an embodiment of the present invention, the method is performed usin...

Embodiment 1

[0087] According to the method of the embodiment of the present invention, ferric iron tetroxide is used as the magnetic core, p-phenylenediamine (PPD) and 1,2,4,5-tetrakis(4-formylphenyl)benzene (TFPB) are functional monomers Synthesis of magnetic covalent organic framework nanoparticles, the preparation process is as follows:

[0088] (a) In a 50 mL two-neck round-bottom flask, 100 mg of ferric oxide and 116 mg of p-phenylenediamine were added to 22 mL of tetrahydrofuran, and ultrasonically treated for 20 minutes.

[0089] (b) Stir the mixture mechanically at 60-70°C for 20-40 minutes, so that part of the p-phenylenediamine is first anchored to the surface of ferric oxide through hydrogen bonds to form a bridge.

[0090] (c) 160 mg of 1,2,4,5-tetrakis(4-formylphenyl)benzene (TFPB) was uniformly dispersed in 8 mL of THF, and it and 1 mL of acetic acid were added dropwise to the above reaction with stirring In the system, after the dropwise addition is completed, the reaction...

Embodiment 2

[0092] For the magnetic covalent organic framework nanomaterial (Fe 3 o 4 @COF(PPD-TFPB)) carried out detailed characterization experiments to demonstrate the successful preparation and excellent physicochemical properties of this magnetic nanoparticle. details as follows:

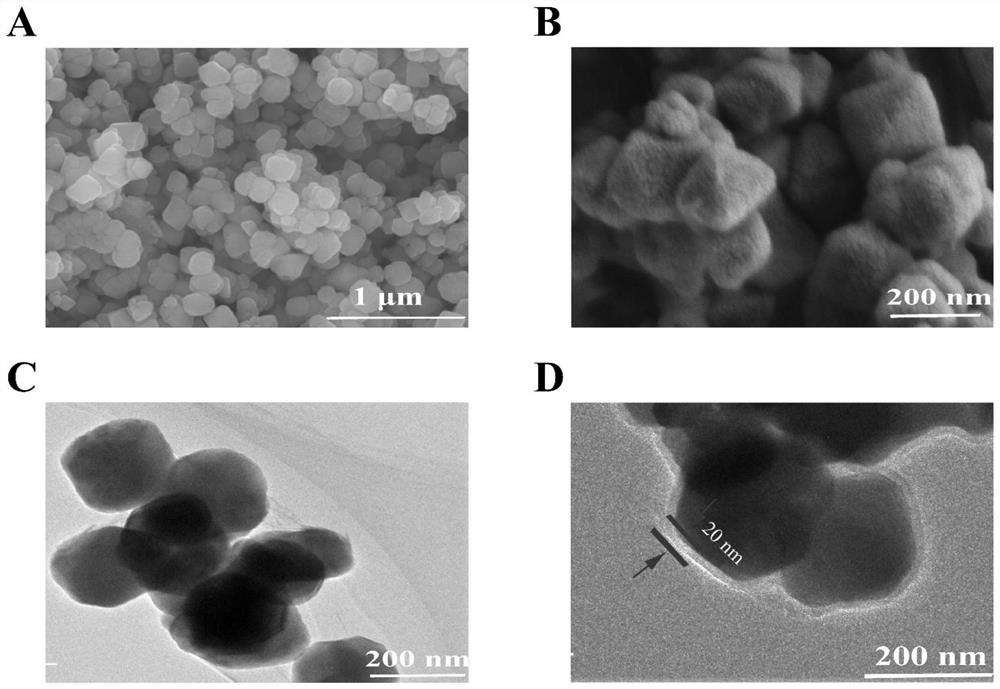

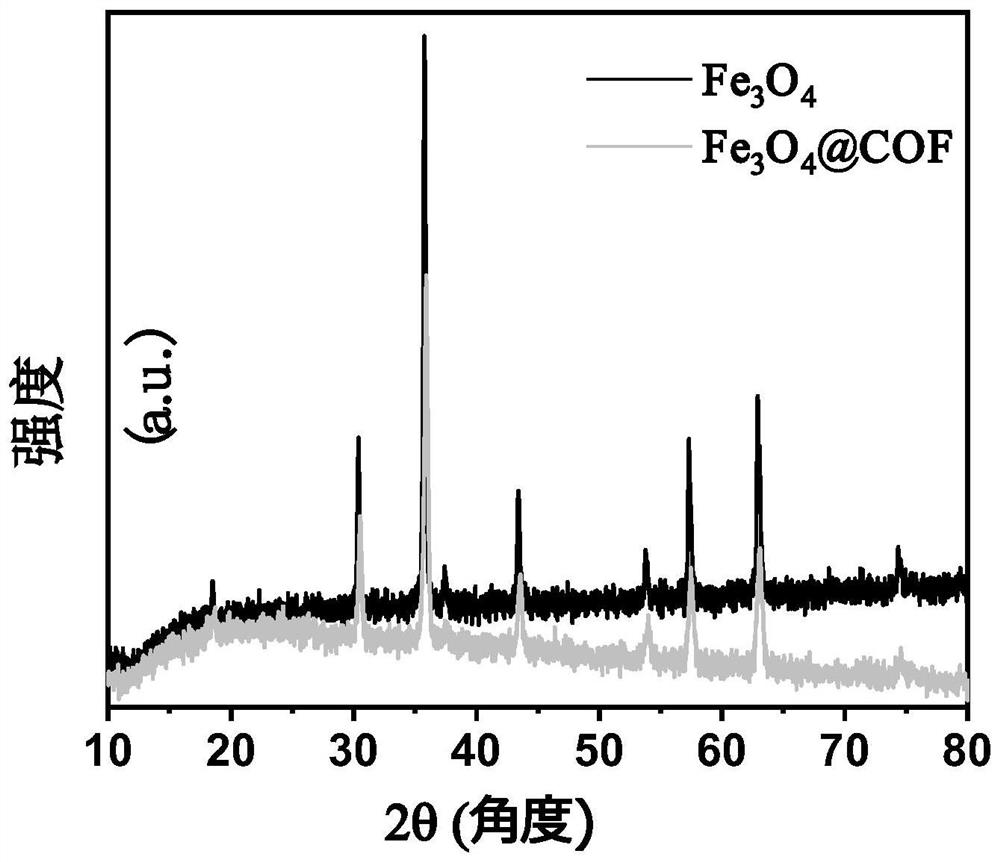

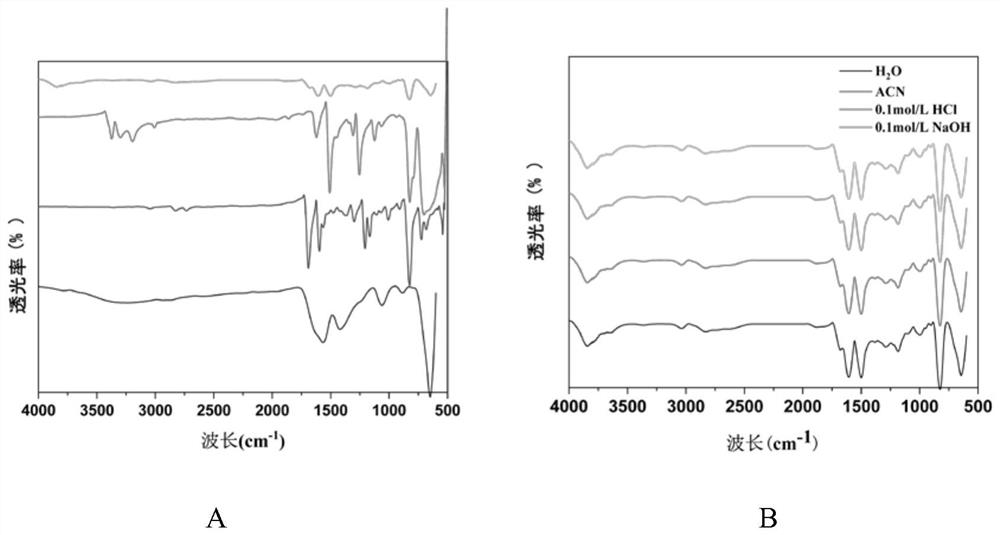

[0093] 1. For ferric oxide (Fe 3 o 4 ) and magnetic covalent organic framework nanomaterials were analyzed by scanning electron microscopy and transmission electron microscopy. The result is as figure 1 As shown, from Fe 3 o 4 ( figure 1 (A)) and Fe 3 o 4 @COF(PPD-TFPB)( figure 1 The SEM image of (B)) can find out the Fe of embodiment 1 3 o 4 and Fe 3 o 4 @COF(PPD-TFPB) has regular octahedral morphology and good dispersion. compared to Fe 3 o 4 , Fe 3 o 4 The surface morphology of @COF(PPD-TFPB) changed obviously, indicating that the COF shell was successfully wrapped in Fe 3 o 4 surface. Fe 3 o 4 (C) and Fe 3 o 4 The TEM image of @COF(PPD-TFPB) further proves that the COF shell i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com