Green and recyclable cellulose solvent and preparation method thereof, and method for realizing cellulose regeneration

A cellulose solvent and cellulose regeneration technology, applied in the field of natural polymers, can solve problems such as poor recycling, insufficient stability, and low solubility, and achieve the effects of loose preparation conditions, broad commercial application prospects, and fast dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

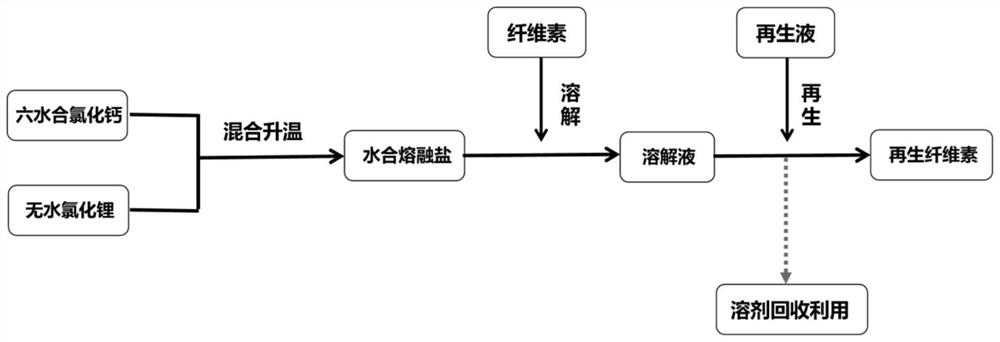

[0031] Step 1: Dissolve 8.0g of calcium chloride hexahydrate at 50.0°C to obtain molten salt of calcium chloride hexahydrate, then slowly add 2.0g of anhydrous lithium chloride to the molten salt of calcium chloride hexahydrate, increasing When the temperature reaches 80.0°C, a colorless and transparent mixed molten salt is obtained;

[0032] Step 2: After heating up the mixed molten salt obtained in Step 1 to 120.0°C, add 0.3g of natural cellulose (Mz=8.0×10 5 ) Slowly add the mixed molten salt, stir at 1000rpm for 5.0h, and keep the temperature at 120.0°C to obtain a concentrated cellulose solution;

[0033] Step 3: Pour the concentrated cellulose solution obtained in step 2 into a glass mold, then put the glass mold into 2.0% ethanol aqueous solution for regeneration, let it rest for 8.0 hours, and then wash away the molten salt with deionized water to obtain the regenerated cellulose hydrogel glue.

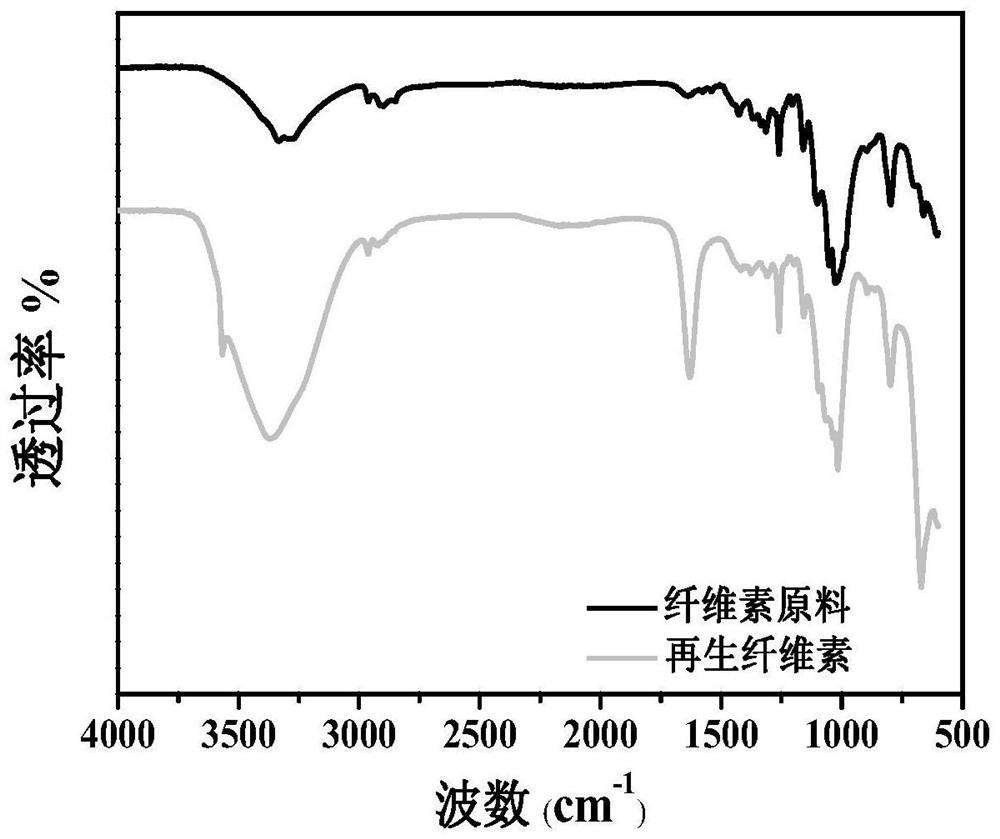

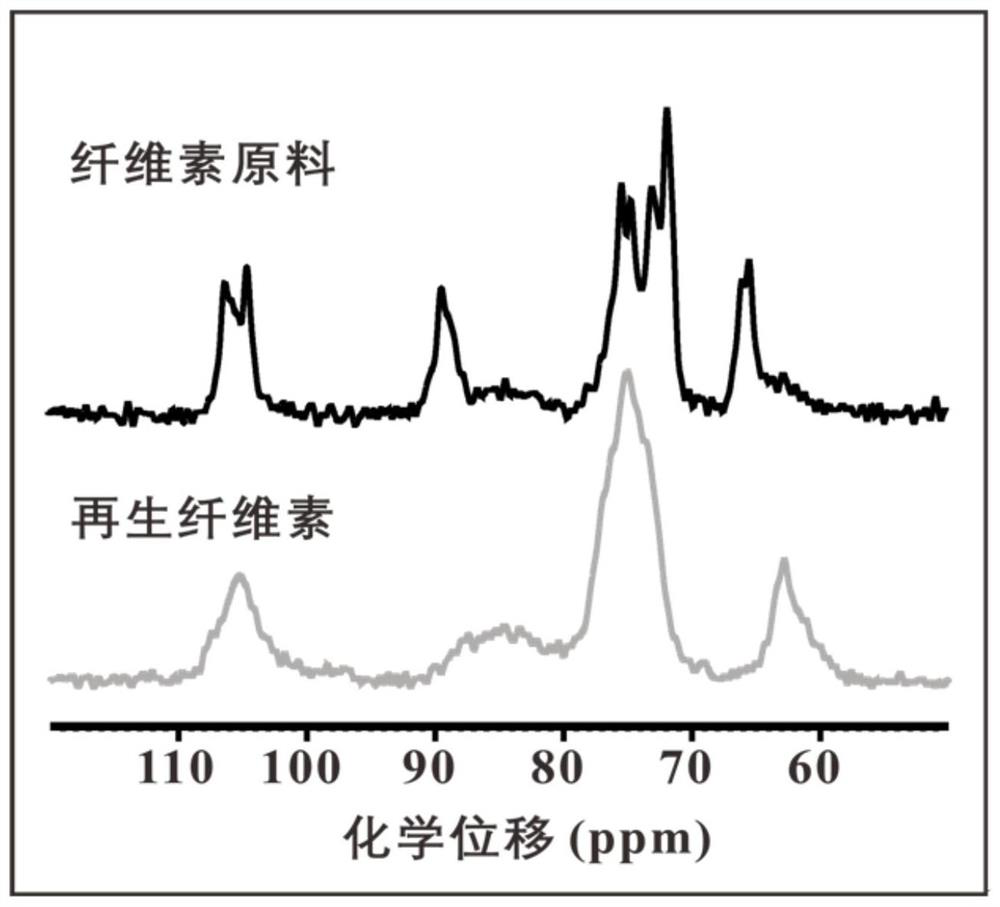

[0034] Through the characterization of the cellulose raw material and r...

Embodiment 2

[0036] Step 1: Dissolve 10.0g of calcium chloride hexahydrate at 50.0°C to obtain molten salt of calcium chloride hexahydrate, then slowly add 2.0g of anhydrous lithium chloride to the molten salt of calcium chloride hexahydrate, increasing When the temperature reaches 80.0°C, a colorless and transparent mixed molten salt is obtained;

[0037] Step 2: After heating up the mixed molten salt obtained in Step 1 to 90.0°C, add 0.12g of natural cellulose (Mz=8.0×10 5 ) Slowly add the mixed molten salt, stir at 1000rpm for 6.0h, and keep the temperature at 90.0°C to obtain a concentrated cellulose solution;

[0038] Step 3: Pour the concentrated cellulose solution obtained in step 2 into a glass mold, then put the glass mold into 10.0% ethanol aqueous solution for regeneration, let it rest for 8.0 hours, and then wash away the molten salt with deionized water to obtain the regenerated cellulose hydrogel glue.

Embodiment 3

[0040]Step 1: Dissolve 9.0g of calcium chloride hexahydrate at 50.0°C to obtain molten salt of calcium chloride hexahydrate, then slowly add 3.0g of anhydrous lithium chloride to the molten salt of calcium chloride hexahydrate, increasing When the temperature reaches 80.0°C, a colorless and transparent mixed molten salt is obtained;

[0041] Step 2: After heating up the mixed molten salt obtained in Step 1 to 110.0°C, add 0.6g of natural cellulose (Mz=8.0×10 5 ) Slowly add the mixed molten salt, stir at 1500rpm for 6.0h, and keep the temperature at 110.0°C to obtain a concentrated cellulose solution;

[0042] Step 3: Pour the concentrated cellulose solution obtained in step 2 into a glass mold, then put the glass mold into 5.0% ethanol aqueous solution for regeneration, let it rest for 8.0 hours, and then wash away the molten salt with deionized water to obtain a regenerated cellulose membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com