Double-loop double-carbon-source rapid directional vapor deposition method

A vapor deposition, double-loop technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems that the uniformity and compactness of carbon-based composite materials need to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

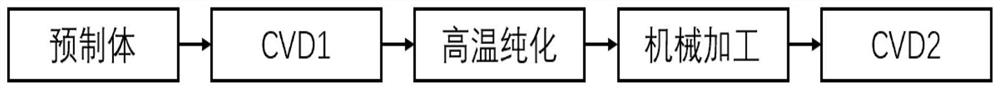

[0028] A dual-loop dual-carbon source rapid directional vapor deposition method, characterized in that dual carbon source gases are used to achieve directional flow through dual loops to form a stable temperature field and thermal flow field to promote the rapid deposition of pyrolytic carbon into the interior of the prefabricated body to achieve The high-efficiency densification of the preform is improved, and the density and uniformity of the carbon-based composite material are improved; the preform pretreatment, primary vapor deposition, high-temperature purification, mechanical processing and secondary vapor deposition steps are sequentially included.

[0029] The primary vapor deposition uses a gaseous carbon source and a solid carbon source.

[0030] The solid carbon source is melamine; the gaseous carbon source is a mixture of propane and methane in a mass ratio of 3:1; the primary vapor deposition time is 18 hours; the temperature is 950°C.

[0031] The secondary vapor...

Embodiment 2

[0034] A double-circuit dual carbon source rapid directional vapor deposition method, which is basically the same as in Example 1, except that the solid carbon source is urea; the gaseous carbon source is formed by mixing propane and methane in a mass ratio of 3.5:1 mixture; the primary vapor deposition time is 25h; the temperature is 1050°C; the secondary vapor deposition is carried out in a dual carbon source gaseous chemical co-deposition device; the carbon source of the dual carbon source gaseous chemical co-deposition device is propylene and For acetylene, the deposition temperature is 920°C, and the deposition rate is 0.5 μm / h; the high-temperature purification treatment specifically includes high-temperature treatment at 780°C for 3.5 hours in an inert gas atmosphere; the inert gas is helium.

Embodiment 3

[0036] A double-loop double carbon source rapid directional vapor deposition method, which is basically the same as in Example 1, except that the solid carbon source is graphite powder; the gaseous carbon source is formed by mixing propane and methane in a mass ratio of 4:1 The mixture; the primary vapor deposition time is 35h; the temperature is 1100°C; the secondary vapor deposition is carried out in a dual carbon source gaseous chemical co-deposition device; the carbon source of the dual carbon source gaseous chemical co-deposition device is propylene and acetylene, the deposition temperature is 950°C, and the deposition rate is 0.7 μm / h; the high-temperature purification treatment specifically includes high-temperature treatment at 820°C for 4 hours in an inert gas atmosphere; the inert gas is neon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap