Air return system and intelligent control system for cotton inspection thermostatic chamber

An intelligent control system and intelligent controller technology, applied in ventilation systems, air humidification systems, applications, etc., can solve problems such as water ingress in channels, health hazards, fire prevention treatment, etc., to achieve extended service life, good filtering effect, and waterproof performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

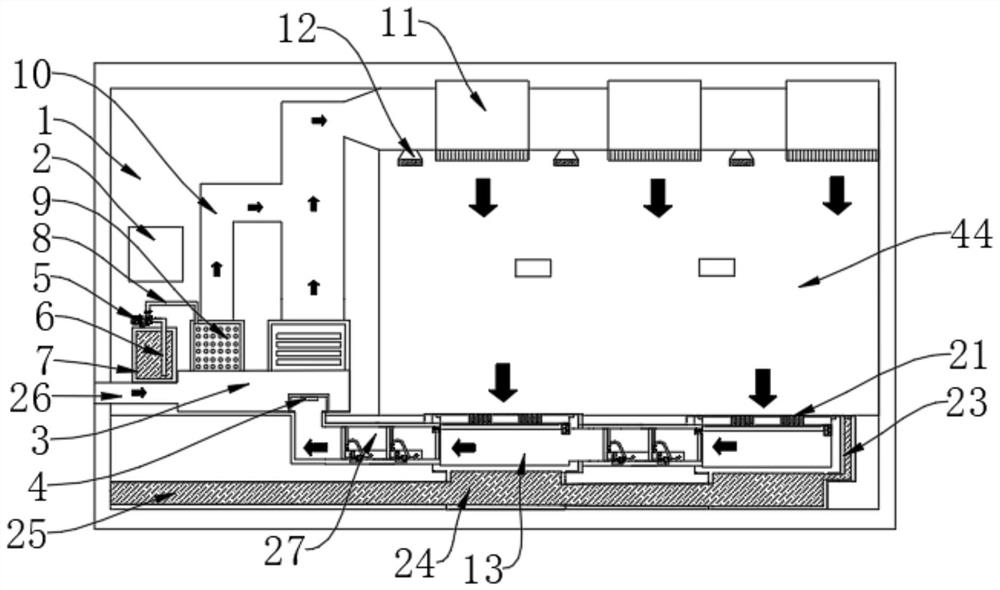

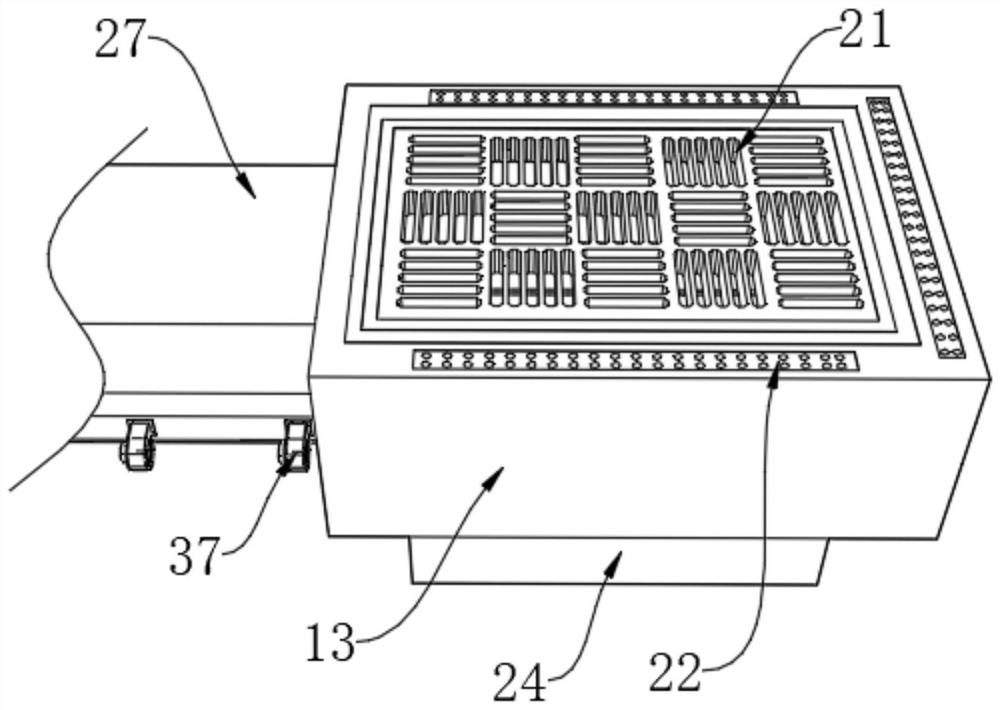

[0030] see Figure 1 to Figure 8 , the present invention provides a return air system and an intelligent control system for a cotton inspection constant temperature room, including a machine room 1, an HVI environment room 44 is fixedly installed on one side of the machine room 1, and an intelligent controller 2 is arranged inside the machine room 1. The interior of the controller 2 adopts PLC, the water pump 5, the first motor 15, the electric telescopic rod 28, the powerful fan 37 and the third motor 43 are all electrically connected with the intelligent controller 2, and the intelligent controller 2 is also equipped with a signal receiving module , and the signal receiving module is connected with the smoke detection sensor 4, the indoor air conditioner 3 is arranged under the intelligent controller 2, the fresh air delivery channel 26 is fixedly installed at the left air inlet of the indoor air conditioner 3, and the air inlet at the bottom of the indoor air conditioner 3 i...

Embodiment 2

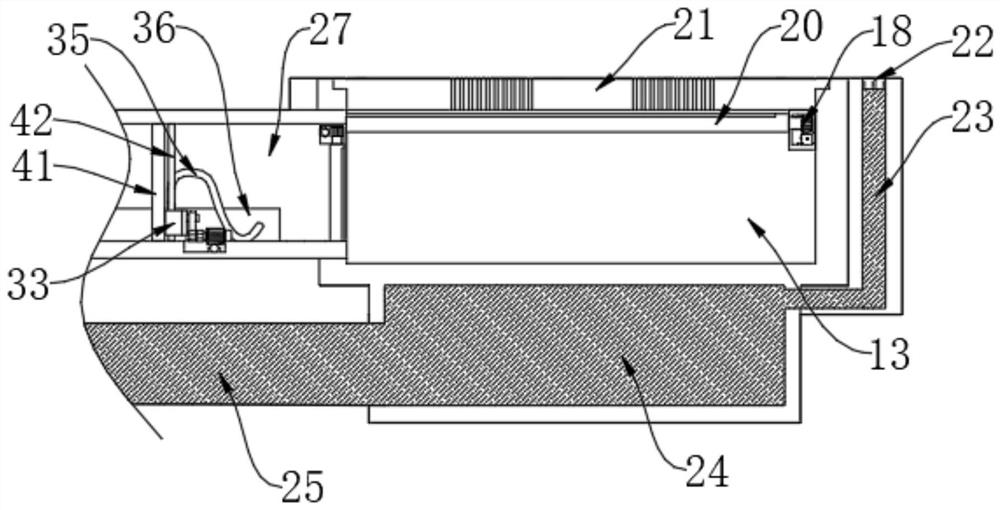

[0034] Embodiment two, on the basis of embodiment one, another embodiment is specifically:

[0035] The automatic filter cleaning mechanism includes an electric telescopic rod 28, a corrugated plate 29, a second gear 30, a first linkage rod 31, a second linkage rod 32, a cleaning protective cover 33, a suction channel 34, a delivery hose 35, and a garbage recovery Case 36, powerful blower fan 37, the 3rd gear 38, the 4th gear 39, cleaning brush 40, cotton fiber filter plate 41, stop bar 42 and the 3rd motor 43, exhaust filter pipe 27 interiors are provided with chute, and slide The groove and the toothed plate 29 are connected by sliding to the output end of the electric telescopic rod 28. A first linkage rod 31 is fixedly installed. A second gear 30 is arranged above the first linkage lever 31. The toothed plate 29 and the second gear 30 are meshed One side of the second gear 30 is fixedly equipped with a first linkage rod 31, and one end of the first linkage lever 31 is mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com