Dicationic co-doped high-nickel ternary layered positive electrode material as well as preparation method and application thereof

A ternary layered, dicationic technology, applied in the direction of positive electrodes, electrical components, battery electrodes, etc., can solve the problems of poor rate performance, capacity and voltage, and achieve the effect of improving rate performance, simple method, and promoting diffusion transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

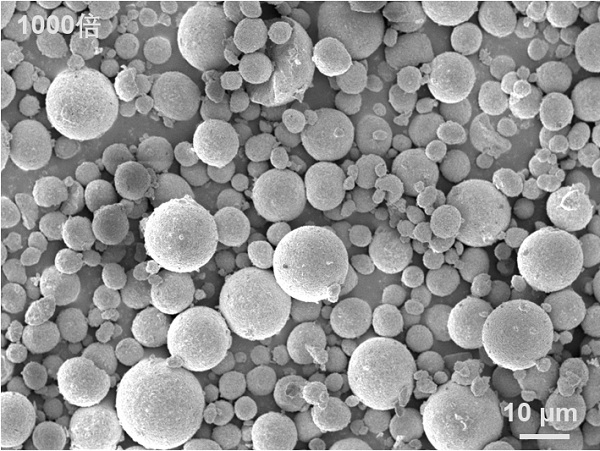

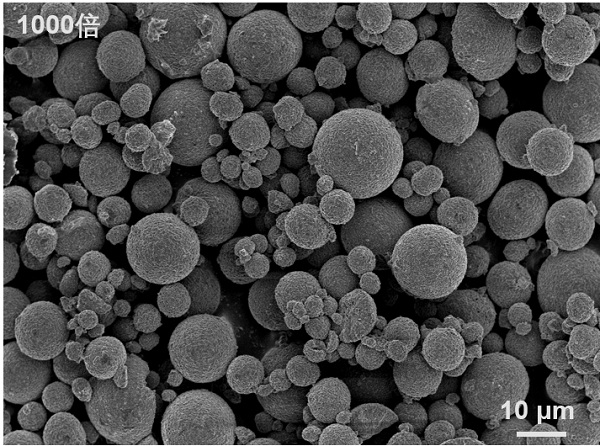

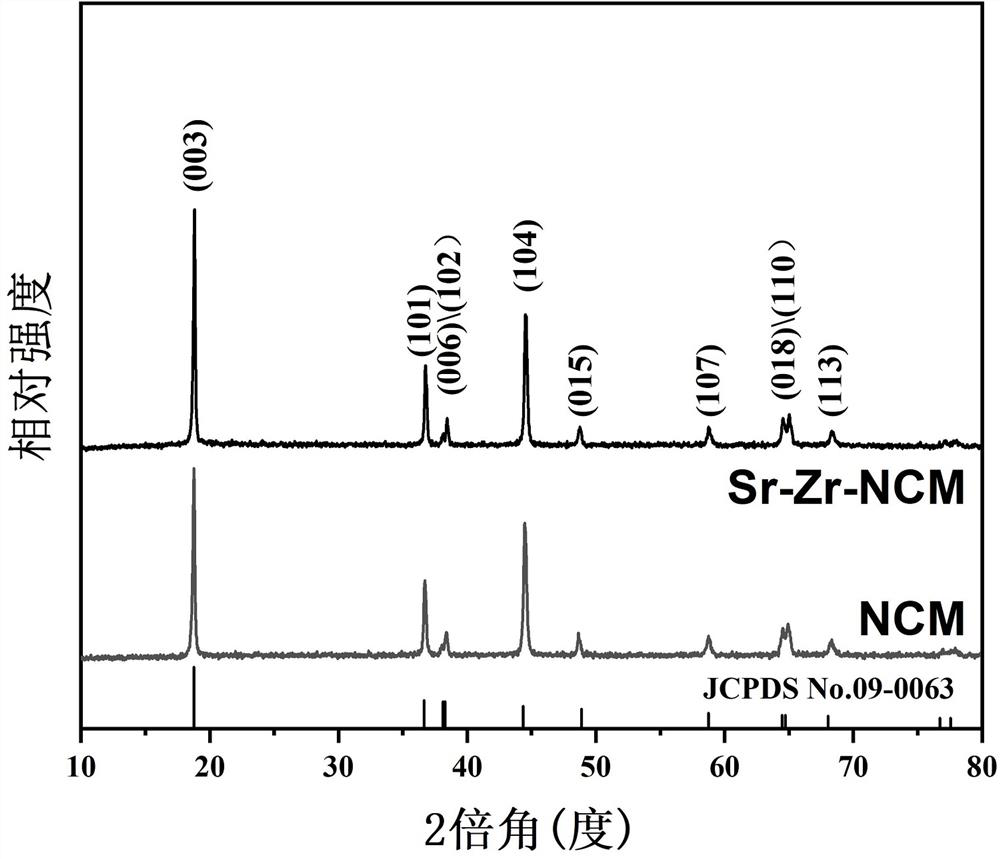

[0040] This embodiment provides a double cation co-doped high-nickel ternary layered positive electrode material, the preparation method of which comprises the following steps:

[0041] S1. Weigh 0.02 mol precursor Ni 0.85 co 0.10 mn 0.05 (OH) 2 , 0.0001 mol dopant SrZrO 3 , 0.021mol lithium source LiOH·H 2 O is placed in an agate ball mill jar to obtain a raw material mixture, in which LiOH·H 2 O excess of 5% mol to prevent evaporation loss during high-temperature sintering; then add solvent isopropanol, wherein the mass ratio of isopropanol to raw material mixture is 10:1;

[0042] S2. Put the ball mill tank loaded with the raw material mixture in S1 in a ball mill, mill at a speed of 500 rpm / min for 12 h, and then vacuum dry at 80° C. for 12 h to obtain a uniformly mixed raw material powder;

[0043] S3. Transfer the raw material powder in S2 to the corundum ark, and then place it in an oxygen atmosphere, firstly raise the temperature to 500°C at a rate of 3°C / min, th...

Embodiment 2

[0045] This embodiment provides a double cation co-doped high-nickel ternary positive electrode material, and its preparation method specifically includes the following steps:

[0046] S1. Weigh 0.02 mol precursor Ni 0.85 co 0.10 mn 0.05 (OH) 2 , 0.0001 mol dopant SrTiO 3 , 0.021mol lithium source LiOH·H 2 O is placed in an agate ball mill jar to obtain a raw material mixture, in which LiOH·H 2 O excess of 5% mol to prevent evaporation loss during high-temperature sintering; then add solvent isopropanol, wherein the mass ratio of isopropanol to raw material mixture is 10:1;

[0047] S2. Put the ball mill tank loaded with the raw material mixture in S1 in a ball mill, mill at a speed of 700 rpm / min for 10 h, and then vacuum dry at 80° C. for 12 h to obtain a uniformly mixed raw material powder;

[0048] S3. Transfer the raw material powder in S2 to the corundum ark, and then place it in an oxygen atmosphere, first raise the temperature to 480 °C at a rate of 5 °C / min, kee...

Embodiment 3

[0050] This embodiment provides a double cation co-doped high-nickel ternary layered positive electrode material, and its preparation method specifically includes the following steps:

[0051] S1. Weigh 0.02 mol precursor Ni 0.85 co 0.10 mn 0.05 (OH) 2 , 0.0001 mol dopant BaTiO 3 , 0.021mol lithium source LiOH·H 2 O is placed in an agate ball mill jar to obtain a raw material mixture, in which LiOH·H 2 O excess of 5% mol to prevent evaporation loss during high-temperature sintering; then add solvent isopropanol, wherein the mass ratio of isopropanol to raw material mixture is 10:1;

[0052] S2. Put the ball mill tank loaded with the raw material mixture in S1 in a ball mill, mill at a speed of 300 rpm / min for 15 hours, and then vacuum dry at 80°C for 12 hours to obtain a uniformly mixed raw material powder;

[0053] S3. Transfer the raw material powder in S2 to the corundum ark, and then place it in an oxygen atmosphere, first raise the temperature to 600 °C at a rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com