Device and method for adsorbing and pretreating coal gasification wastewater by residual sludge and application of device and method

A technology for coal gasification wastewater and excess sludge, which is used in adsorption water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

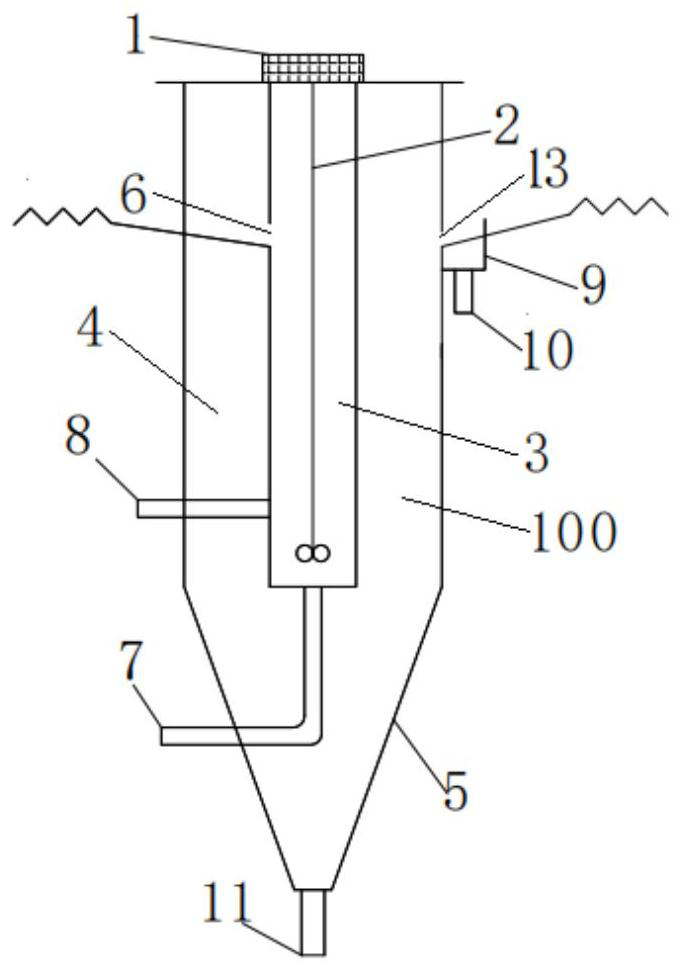

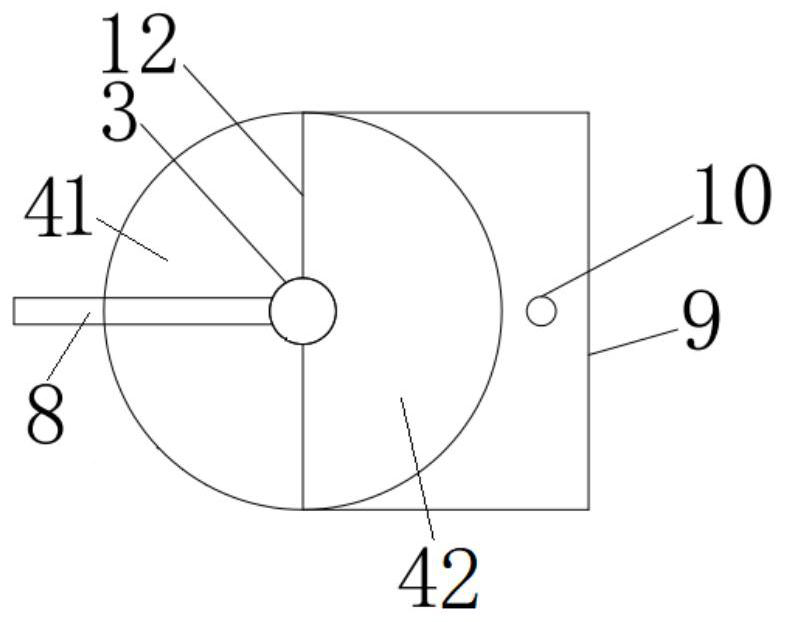

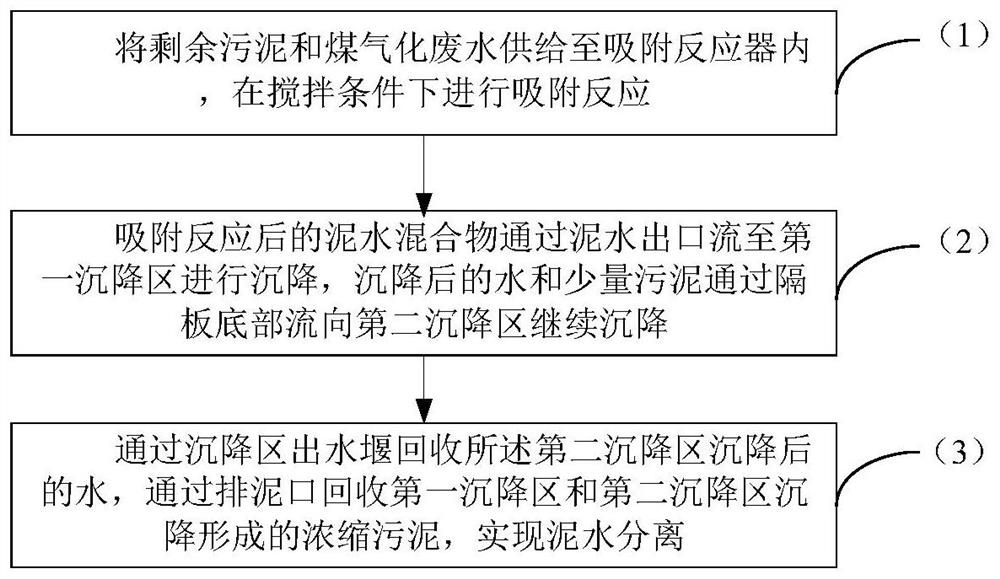

[0069] The device is made of plexiglass, the effective volume of the adsorption reactor is 105mL, and the effective volume of the settling zone is 470mL. Flow the excess sludge and coal gasification wastewater in the aerobic section of the biochemical pool into the adsorption reactor through the water inlet and sludge inlet, so that the solid-liquid ratio of the excess sludge and coal gasification wastewater is 0.5-1g / L, turn on the stirring device, The sludge adsorption area is mechanically stirred, and the adsorption reaction is carried out at a stirring rate of 200-300 rpm; the temperature in the adsorption reactor is kept at 30-35°C, and the remaining sludge and coal gasification wastewater in the adsorption reactor The residence time is 2 hours; the mud-water mixture after the adsorption reaction flows to the first settling zone through the mud-water outlet for settlement, and the settled water and a small amount of sludge flow to the second settling zone through the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com