Dental composite material, multilayer dental composite material and preparation method and application thereof

A technology of composite materials and dental materials, applied in dental preparations, dentistry, dental prostheses, etc., can solve the problem of not being able to effectively improve the strength and toughness of composite materials, reduce the interface strength between fillers and matrix, increase the overall density of dental composite materials, etc. problems, to achieve the effects of inhibiting crack growth, enhancing mechanical properties, and long fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment provides a method for preparing a nanocomposite material, which specifically includes the following steps:

[0070] (1) Mix bisphenol A glycerol dimethacrylate (BisGMA, yellow liquid) and triethylene glycol dimethacrylate (TEGDMA, colorless liquid) at a mass ratio of 1:1, and then add camphor Quinone (orange powder) and 2-(dimethylamino) ethyl methacrylate (colorless liquid), stirring reaction until the mixture becomes translucent dark yellow liquid, promptly obtains the dental polymer precursor; Wherein, camphorquinone The added amount accounts for 2 mol% of the total molar weight of the dental polymer precursor; 2-(dimethylamino) ethyl methacrylate accounts for 2 mol% of the total molar weight of the dental polymer precursor.

[0071] (2) Pretreatment of zirconia nanoparticles: adding zirconia nanoparticles to ethanol solution, using a high-speed disperser and an ultrasonic probe for dispersion treatment, followed by ultrasonic washing and centrifugal ...

Embodiment 2

[0075] This embodiment provides a method for preparing a multilayer dental composite material, comprising the following steps:

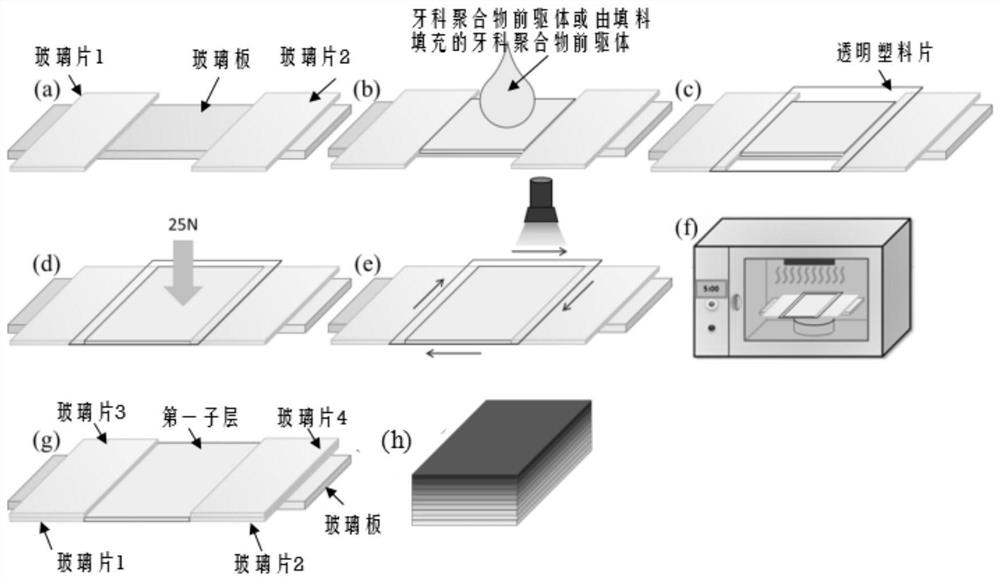

[0076] (1) if figure 2As shown, the size will be 76.2×25.4×1mm 3 The glass plate is placed horizontally on a plane, and two pieces of size 32×24×0.2mm are adhered to the upper surface of the glass plate through an adhesive spacer. 3 The glass sheet, leaving 28.2×25.4×0.2mm between the two glass sheets 3 Clearance( figure 2 in (a)).

[0077] (2) drop the zirconia nanoparticle-filled dental polymer precursor ( figure 2 In (b)); then adopt a transparent plastic sheet to cover the gap, and the lower surfaces of the two ends of the transparent plastic sheet are respectively abutted against the upper surfaces of the two glass sheets ( figure 2 In (c)); Place a 25N weight on the upper surface of the transparent plastic sheet ( figure 2 (d)), extruding the zirconia nanoparticle-filled dental polymer precursor in the gap until the zirconia nanopart...

Embodiment 3

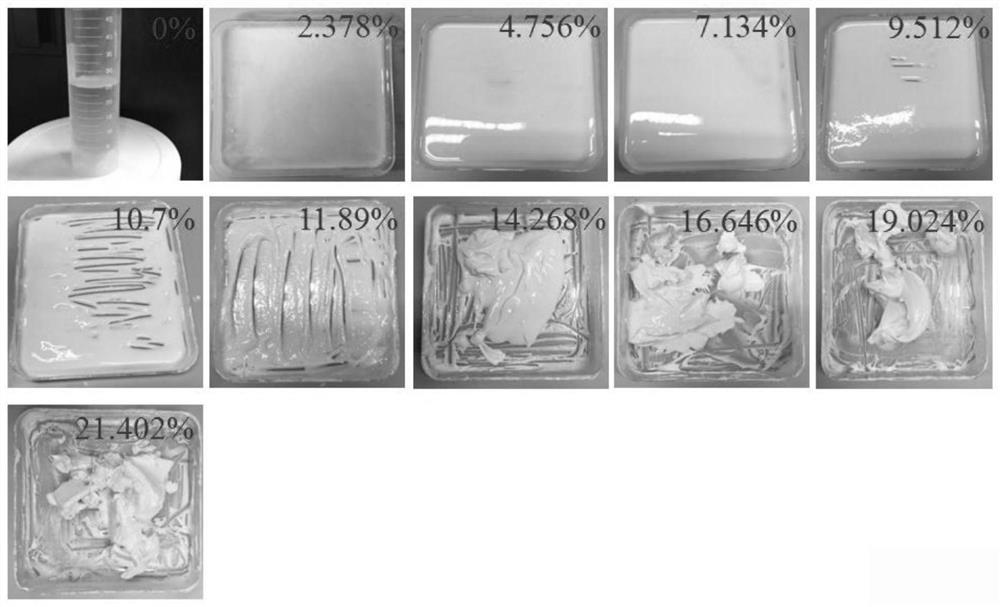

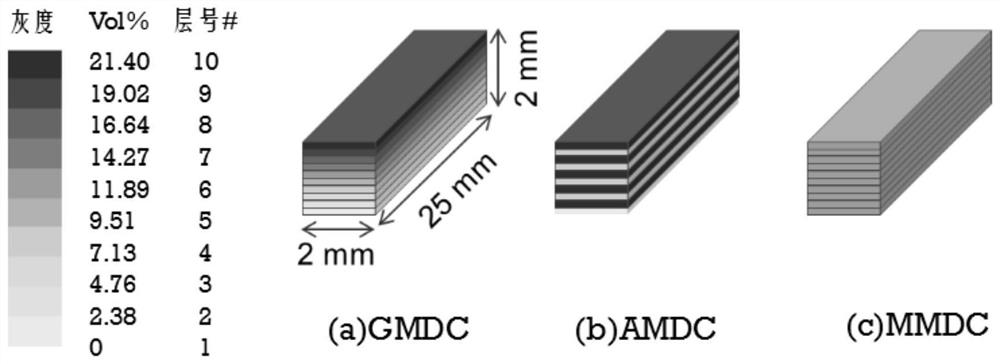

[0080] This embodiment constructs and obtains three kinds of independent dental composite materials according to the method of embodiment 1 and 2, as image 3 shown.

[0081] The first, gradient multilayer dental composite (GMDC):

[0082] Such as image 3 As shown in (a), the content of zirconia nanoparticles in the dental composite material of each layer shows a gradient linear change along the thickness direction, the content is from 0vol% to 21.40vol%, and the increment of each layer is 2.378vol%, a total of 10 layer structure.

[0083] The second, Alternating Multilayer Dental Composite (AMDC):

[0084] Such as image 3 As shown in (b), 5 layers of pure resin materials (i.e. no zirconia nanoparticles added in Example 1) and 5 layers of zirconia nanoparticles added in an amount of 21.40vol% dental composites are arranged alternately along the thickness direction .

[0085] The third type, monotonic multilayer dental composite (MMDC):

[0086] Such as image 3 As sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Feature size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com