Hydrocracking catalyst

A hydrocracking and catalyst technology, applied in the field of oil hydrogenation, can solve the problems of difficult control, cumbersome catalyst preparation process, and high catalyst preparation cost, so as to reduce operational risks, improve hydrogenation activity, improve hydrogenolysis activity and The effect of chain scission activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

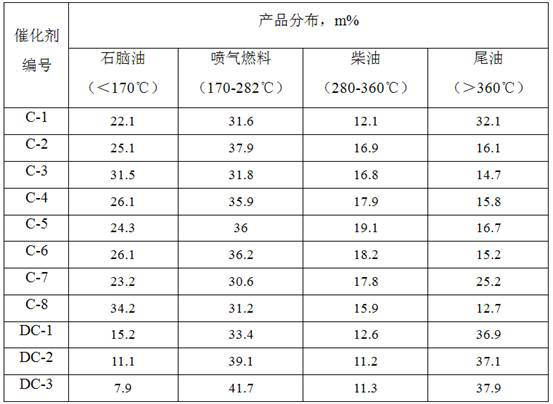

Examples

Embodiment 1

[0038] (1) The ammonium heptamolybdate solution was impregnated into Y-type molecular sieves, then ultrasonically treated at room temperature for 3 hours, then dried at 150°C for 4 hours, calcined at 400°C for 5 hours, and then treated with 1.5%H 2 The hydrogen of S is vulcanized, the vulcanization temperature is 320°C, the vulcanization pressure is 3.2MPa, the vulcanization time is 4h, and then in N 2 The atmosphere is lowered to room temperature to obtain a modified molecular sieve.

[0039] (2) Mix the modified molecular sieve prepared in step (1) with alumina powder, nitric acid, starch, and deionized water evenly, wherein the mass ratio of modified molecular sieve: alumina powder: nitric acid: starch: deionized water is 5: 95: 4:3:60, then kneading, extrusion molding, and then in N 2 Dry at 90°C for 10 hours in the atmosphere, and bake at 550°C for 3 hours to obtain a modified alumina carrier, in which the content of Y-type molecular sieve is 5%.

[0040] (3) Impregnate...

Embodiment 2

[0043] (1) Immerse ammonium heptamolybdate solution into Y-type molecular sieves, then ultrasonically treat at room temperature for 3 hours, then dry at 120°C for 6 hours, bake at 450°C for 3 hours, and then use 1.5%H 2 The hydrogen of S is vulcanized, the vulcanization temperature is 340°C, the vulcanization pressure is 3.6MPa, the vulcanization time is 4h, and then in N 2 The atmosphere is lowered to room temperature to obtain a modified molecular sieve.

[0044] (2) Mix the modified molecular sieve prepared in step (1) with alumina powder, nitric acid, starch, and deionized water evenly, wherein the mass ratio of modified molecular sieve: alumina powder: nitric acid: starch: deionized water is 10: 90: 4:3:50, then kneading, extrusion molding, and then in N 2 Dry at 90°C for 10 hours in the atmosphere, and bake at 600°C for 3 hours to obtain a modified alumina carrier, in which the content of Y-type molecular sieve is 10%.

[0045] (3) Immerse an equal volume of nickel nit...

Embodiment 3

[0048] (1) Immerse the ammonium metatungstate solution into Y-type molecular sieves, then ultrasonically treat at room temperature for 3 hours, then dry at 130°C for 5 hours, bake at 350°C for 3 hours, and then use 1.5%H 2 The hydrogen of S is vulcanized, the vulcanization temperature is 340°C, the vulcanization pressure is 4.0MPa, the vulcanization time is 4h, and then in N 2 The atmosphere is lowered to room temperature to obtain a modified molecular sieve.

[0049] (2) Mix the modified molecular sieve prepared in step (1) with alumina powder, nitric acid, starch, and deionized water evenly, wherein the mass ratio of modified molecular sieve: alumina powder: nitric acid: starch: deionized water is 15: 85: 4:3:50, then kneading, extrusion molding, and then in N 2 Dry at 90°C for 10 hours in the atmosphere, and bake at 600°C for 3 hours to obtain a modified alumina carrier, in which the content of Y-type molecular sieve is 15%.

[0050] (3) Immerse an equal volume of nickel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com