Rare earth element-doped barium titanate giant dielectric ceramic material and preparation method thereof

A technology of ceramic materials and rare earth elements, which is applied in the field of giant dielectric materials, can solve the problems of low dielectric constant, strong temperature dependence of dielectric constant, high loss, etc., and achieve good temperature stability and good frequency stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

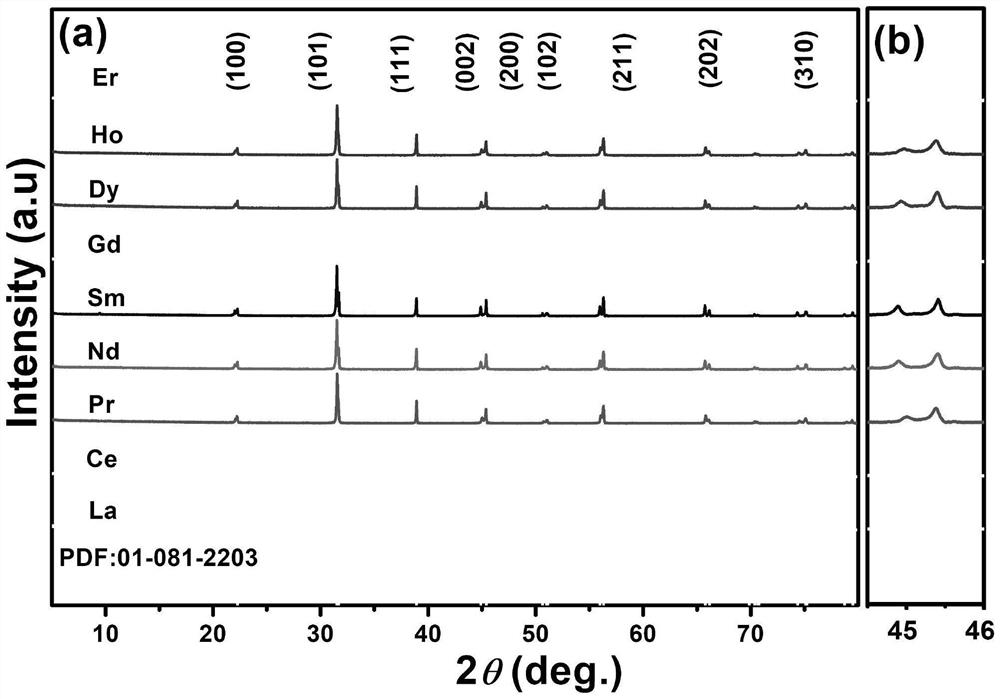

[0030] A method for preparing a barium titanate giant dielectric ceramic material doped with rare earth elements, the preparation method comprising the following steps:

[0031] (1) According to the general chemical formula Ba 0.99 Re 0.01 TiO 3 , Weigh the corresponding barium source BaCO 3 , titanium source TiO 2 and rare earth oxide source, the corresponding Re of embodiment 1-9 is La, Ce, Pr, Nd, Sm, Gd, Dy, Ho and Er respectively, and the rare earth oxide source correspondingly added is La respectively 2 o 3 , CeO 2 、Pr 6 o 11 、Nd 2 o 3 、Sm 2 o 3 、Gd 2 o 3 、Dy 2 o 3 、Ho 2 o 3 、Er 2 o 3 , and then using absolute ethanol as a dispersant, zirconia balls as a ball milling medium, the ball milling time is 6 hours, and drying after ball milling to obtain a mixed powder A;

[0032] (2) The mixed powder A is calcined in the air at a temperature of 1000°C, and then ball milled for the second time, with absolute ethanol as the dispersant, zirconia balls as the bal...

Embodiment 10-18

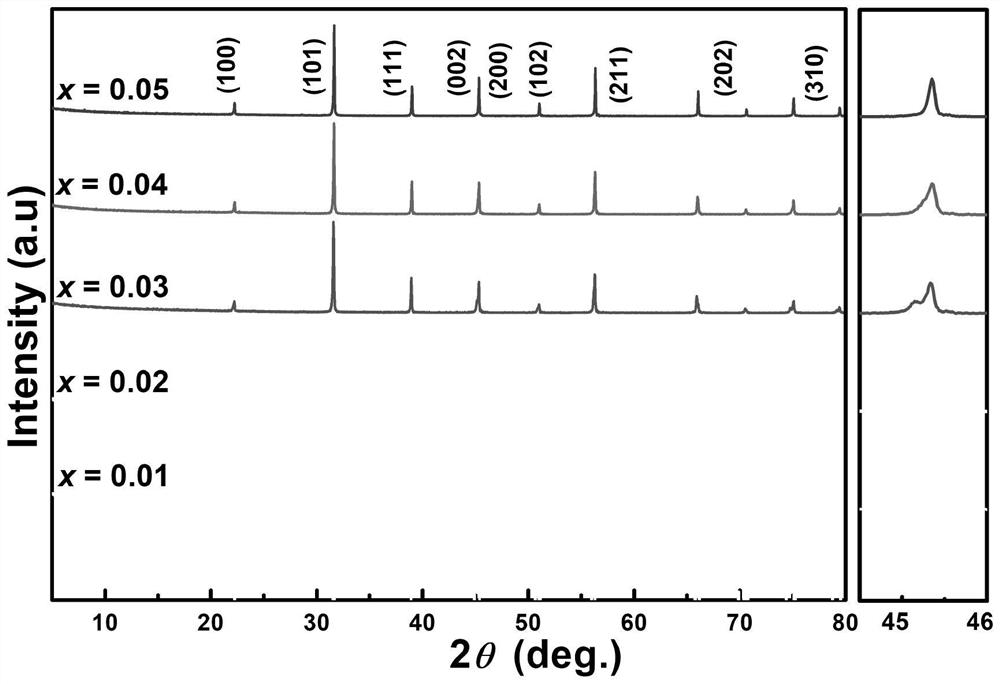

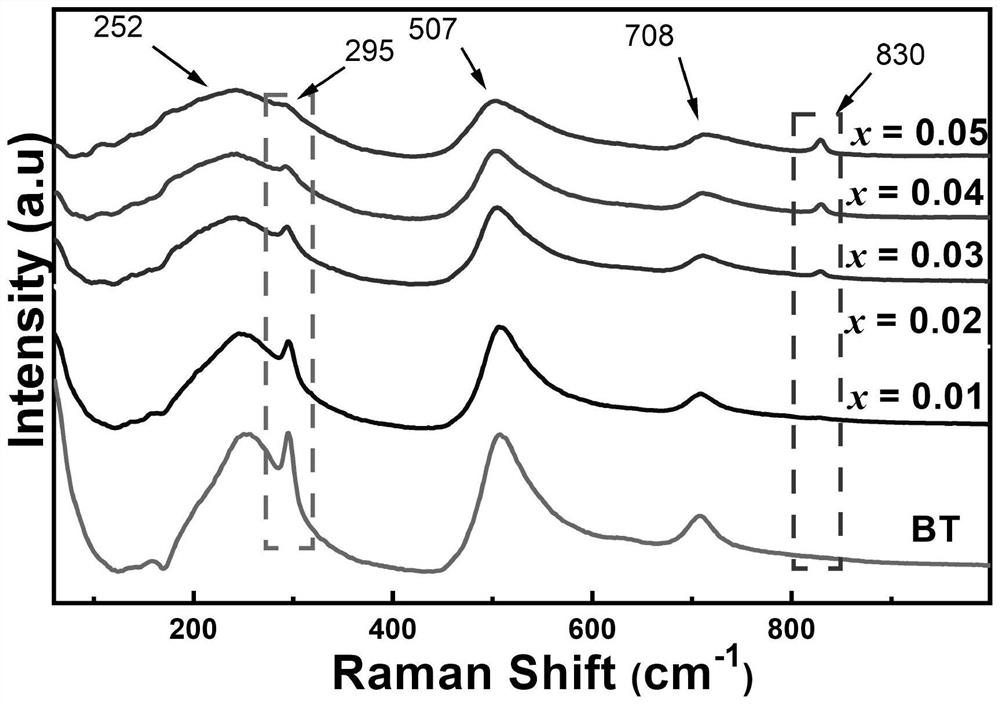

[0037] The difference between this embodiment and Embodiment 1 is that the general formula of the barium titanate giant dielectric ceramic material doped with rare earth is Ba 0.98 Re 0.02 TiO 3 , correspondingly its step (1) weighs and adds corresponding rare earth oxide source according to this general formula, and other steps are identical with embodiment 1.

Embodiment 19-27

[0039] The difference between this embodiment and Embodiment 1 is that the general formula of the barium titanate giant dielectric ceramic material doped with rare earth elements is Ba 0.97 Re 0.03 TiO 3 , correspondingly its step (1) weighs and adds corresponding rare earth oxide source according to this general formula, and other steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com