Nutrient solution suitable for vegetable seedling culture in plant factory and seedling culture method

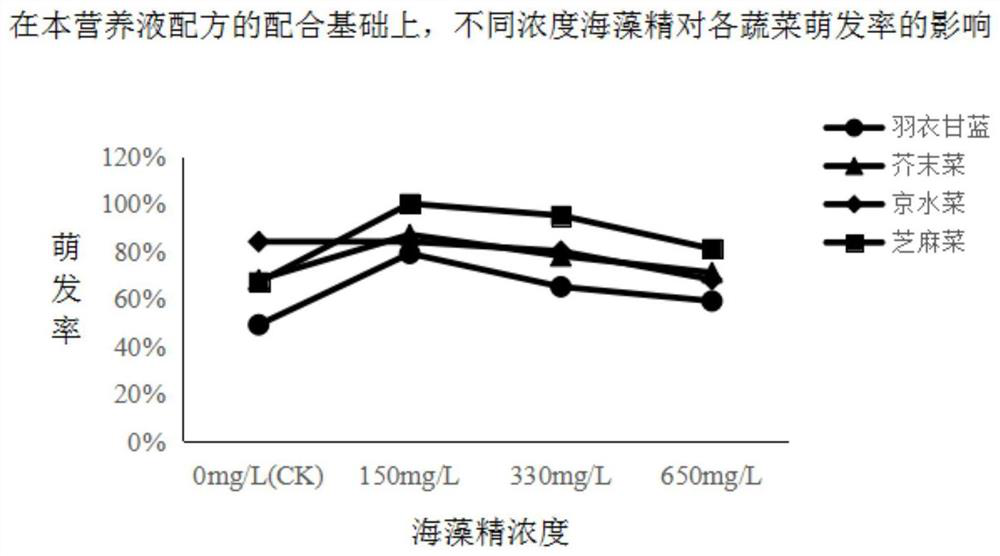

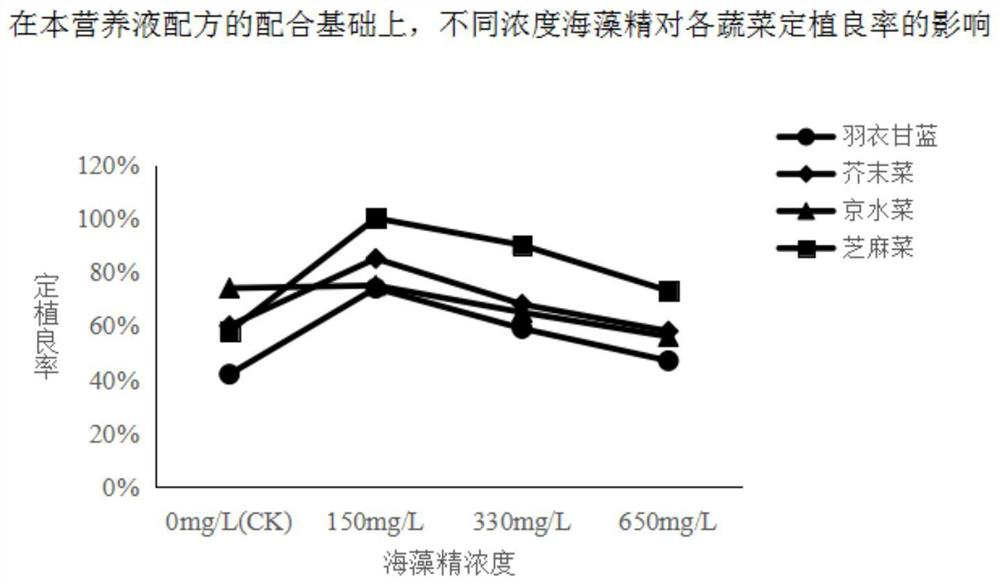

A nutrient solution and factory technology, which is applied in the field of plant factory vegetables, can solve the problems of long seedling raising time, low germination rate, underdeveloped root system, etc., and achieve the effects of short seedling raising time, increased sugar content, and well-developed root system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A nutrient solution suitable for growing vegetable seedlings in a plant factory, the nutrient solution is dissolved in water, its conductivity value is 1.0-1.5mS / cm, and the concentration of each component dissolved in water is as follows:

[0055] Calcium nitrate: 136.603~218.565g / T;

[0056] Potassium nitrate: 182.100~291.360g / T;

[0057] EDTA chelated iron: 5.775~9.240g / T;

[0058] Potassium dihydrogen phosphate: 27.225~43.560g / T;

[0059] Ammonium dihydrogen phosphate: 20.025~32.040g / T;

[0060] Medicinal magnesium sulfate: 44.817~71.707g / T;

[0061] Borax: 0.540~0.864g / T;

[0062] Manganese sulfate: 0.256~0.410g / T;

[0063] Zinc sulfate: 0.120~0.192g / T;

[0064] Copper sulfate: 0.022~0.035g / T;

[0065] Sodium molybdate: 0.019~0.031g / T;

[0066] Pure seaweed extract: 150g / T.

[0067] The working principle of the above-mentioned technical scheme is as follows:

[0068] The nutrient solution is composed of calcium nitrate, potassium nitrate, EDTA chelated ir...

Embodiment 2

[0072] The above-mentioned nutrient solution is dissolved in water, and its conductivity value is 1.0mS / cm. The concentration of each component dissolved in water is as follows:

[0073] Calcium nitrate 136.603g / T, potassium nitrate 182.100g / T, EDTA chelated iron 9.240g / T, potassium dihydrogen phosphate 27.225g / T, ammonium dihydrogen phosphate 32.040g / T, medicinal magnesium sulfate 71.707g / T, Borax 0.864g / T, manganese sulfate 0.410g / T, zinc sulfate 0.192g / T, copper sulfate 0.035g / T, sodium molybdate 0.031g / T, pure seaweed extract 150g / T.

Embodiment 3

[0075] The above-mentioned nutrient solution is dissolved in water, and its conductivity value is 1.3mS / cm. The concentration of each component dissolved in water is as follows:

[0076] Calcium nitrate 150.000g / T, potassium nitrate 182.100g / T, EDTA chelated iron 9.240g / T, potassium dihydrogen phosphate 27.225g / T, ammonium dihydrogen phosphate 32.040g / T, medicinal magnesium sulfate 71.707g / T, Borax 0.864g / T, manganese sulfate 0.256g / T, zinc sulfate 0.1200.192g / T, copper sulfate 0.035g / T, sodium molybdate 0.031g / T, pure seaweed extract 150g / T.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity value | aaaaa | aaaaa |

| Conductivity value | aaaaa | aaaaa |

| Conductivity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com