Method and system for preparing ethylbenzene and hydrogen by using refinery dry gas

A refinery dry gas and hydrogen technology, applied in the fields of chemical industry and oil refining, can solve the problems of lack of effective utilization means of ethane resources, and achieve the effects of comprehensive utilization of energy, reduction of investment, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

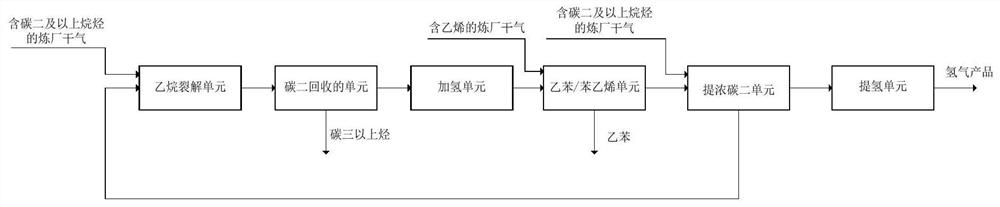

[0037] According to one embodiment of the invention, when the refinery dry gas is rich in ethane, the refinery dry gas is added from step (1) and / or step (5).

[0038] According to one embodiment of the invention, when the refinery dry gas is rich in ethylene, the refinery dry gas is added from step (4).

[0039] According to one embodiment of the present invention, when the refinery dry gas is rich in ethane and ethylene, the refinery dry gas is added from at least one of steps (1), (4) and (5).

[0040] In the present invention, preferably, the method further comprises: (6) hydrogen extraction: separating hydrogen from hydrogen-rich components.

[0041] In the present invention, in step (3), preferably, the method further comprises: using aromatic hydrocarbon to absorb heavy components in the obtained hydrogenated product. The adoption of this preferred embodiment is more conducive to the removal of heavy components, impurities and the like in the obtained hydrogenated product. ...

Embodiment 1

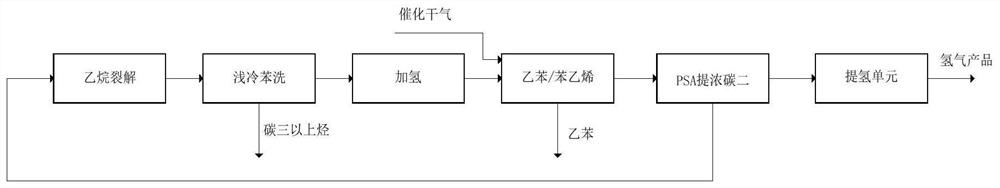

[0093] (1) adopt such as Figure 2 As shown in the process, the ethane-rich gas is sent to an ethane cracking unit for cracking, and the cracked gas obtained is washed in an oil washing tower. The cracked gas absorbs heavy components and part of heat in the wax oil (distillation range is 275℃) in the oil washing tower, then sent to a water cooler for cooling to 40℃, and then compressed to increase the pressure of the cracked gas to 3.5MPa, thus obtaining the compressed and cooled cracked gas.

[0094] (2) sending the cracked gas after compression and cooling into a C2 recovery unit, recovering C2 components in a benzene absorption tower by adopting a shallow cold benzene washing process, and separating C2 components in the benzene absorption tower; See Table 3 for the amount of ethylene entering the C2 recovery unit, the amount of ethylene recovered by the C2 recovery unit and the ethylene recovery rate; The conditions of benzene absorption tower in the shallow cold benzene washing...

Embodiment 2

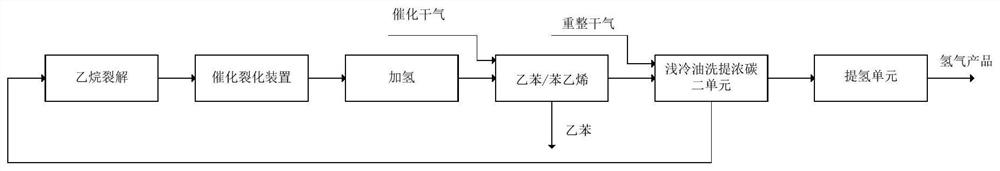

[0100] (1) adopt such as Figure 3 As shown in the process, the ethane-rich gas is sent to an ethane cracking unit for cracking, and the cracked gas obtained is washed in an oil washing tower. The cracked gas absorbs heavy components and part of heat in the wax oil (distillation range is 275℃) in the oil washing tower, then sent to a water cooler for cooling to 40℃, and then compressed to increase the pressure of the cracked gas to 3.5MPa, thus obtaining the compressed and cooled cracked gas.

[0101] (2) sending the compressed and cooled cracked gas into a catalytic cracking unit (C2 recovery unit) to separate C2 components; See Table 3 for the amount of ethylene entering the C2 recovery unit, the amount of ethylene recovered by the C2 recovery unit and the ethylene recovery rate;

[0102] (3) In the presence of a hydrogenation catalyst, the recovered C2 component is selectively hydrogenated to remove alkynes and dienes to obtain a hydrogenated product, and benzene is used to abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com