Thermoelectric material based on polythiophene and preparation method and application thereof

A technology of thermoelectric materials and polythiophene, which is applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of limited research and practical application of organic thermoelectric materials, and achieve reduced electron transport bandgap, high electron transport rate, and redox stability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

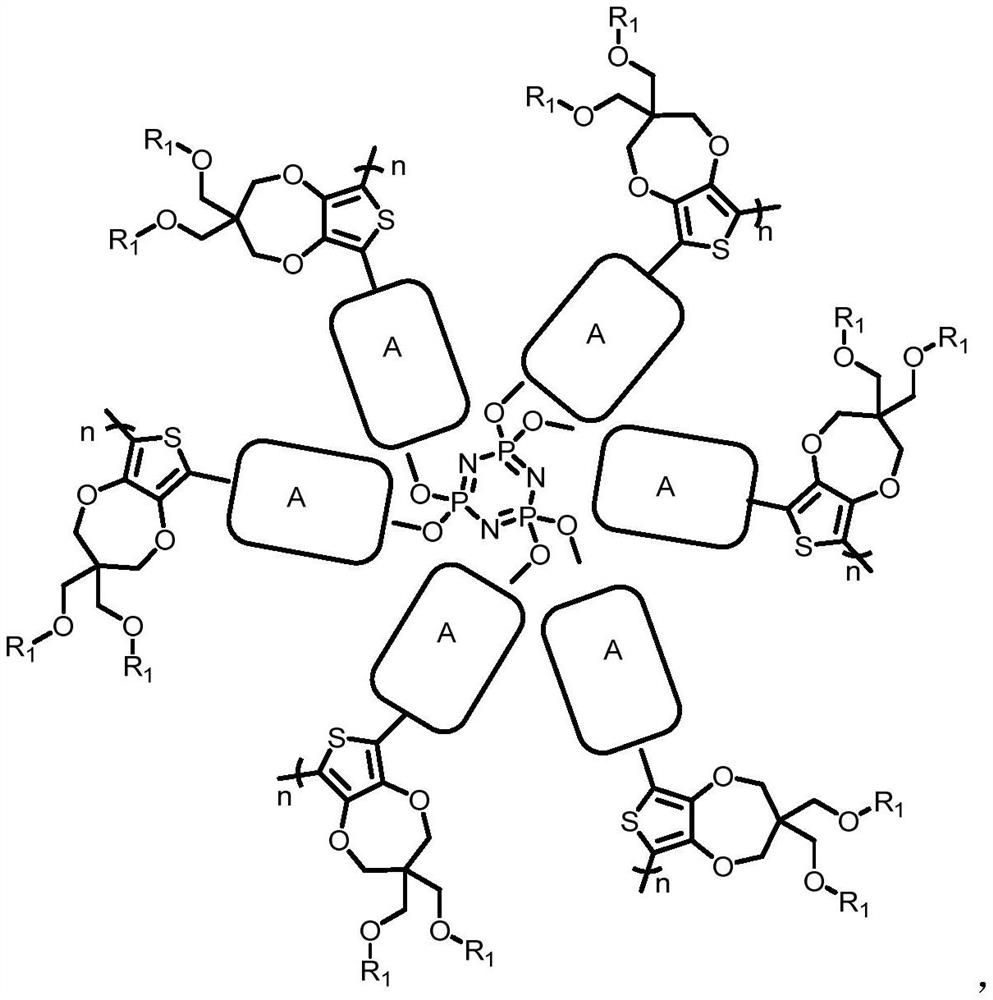

[0091] The preparation steps of thermoelectric materials include:

[0092] (1) Mix 21mmol 3,4-dimethoxythiophene, 42mmol 2,2-bisbromomethylpropanediol, 2.1mmol p-toluenesulfonic acid and 200mL toluene in a 500mL flask equipped with a Soxhlet extractor. A 4A type molecular sieve was installed in the cellulose thimble, the solution was refluxed overnight, the reaction product was cooled and washed once with water, the toluene was removed under vacuum conditions, and the crude product was purified by silica gel column chromatography with n-hexane / dichloromethane (volume ratio 3:1). product, 3,3-bisbromomethyl-3,4-dihydrothieno[3,4-b][1,4]dioxetane was obtained. 1H NMR (400MHz, Chloroform-d) δ6.50(s,2H),4.10(s,4H),3.61(s,4H),1.58(s,5H),1.50–1.15(m,4H),1.03– 0.71(m,2H).

[0093] Concrete synthetic route is as follows:

[0094]

[0095] (2) 50mL DMF, 17.54mmol C 6 h 13 OH, 35.08mmol NaH were mixed in a 250mL flame-dried round bottom flask, heated at 110°C overnight, and then...

Embodiment 2

[0117] The difference from Example 1 is that the C in the step (2) 6 h 13 OH is replaced by C 8 h 17 OH, the synthetic route to obtain the thermoelectric material is as follows:

[0118]

Embodiment 3

[0120] The difference from Example 1 is that the C in the step (2) 6 h 13 OH is replaced by C 4 h 9 OH, the synthetic route to obtain the thermoelectric material is as follows:

[0121]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com