Ultra-small particle size single crystal nickel-cobalt-manganese ternary positive electrode material and preparation method thereof

A cathode material, nickel-cobalt-manganese technology, used in battery electrodes, electrical components, circuits, etc., to improve insertion and extraction, improve electrochemical performance, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the present invention comprises the steps:

[0030] 1) The high-nickel ternary precursor Ni 0.83 co 0.12 mn 0.05 (OH) 2 , lithium source and modification additives are mixed evenly for calcination, the sintering temperature rises at 230°C to 780°C, the sintering time is 4 to 8 hours, the constant temperature section is at 800 to 920°C, and the time is 7 to 15 hours to obtain oxidation modification high-nickel ternary cathode material;

[0031] Among them, the molar ratio of the precursor to the lithium source is 100: (103~110), the D50 of the PSD of the precursor is 2~5um; the lithium source is lithium hydroxide, and the D50 of the PSD is 2~5um; the modification additive is Containing at least one oxide, hydroxide or fluoride of Zr, Mg, Ti, Ce, Mo, Al, W, Nb, B or Sr elements, the D50 of the particle size PSD is 10-100nm, and the modification additive is added The amount is 100ppm-5000ppm of the total mass of high-nickel ternary precursor ...

Embodiment 1

[0038] 1) Mix the high-nickel ternary precursor, lithium source lithium hydroxide and modification additives evenly for calcination. The sintering temperature rises to 500°C within 6 hours, and the constant temperature section is 850°C for 10 hours. Oxidation-modified high-nickel ternary cathode material;

[0039] Among them, the total mass parts of the high-nickel ternary precursor and lithium hydroxide are 205 parts, and the modification aid is 0.00205 parts by mass of Mg(OH) 2 , that is, the amount added is 2050ppm. The molar ratio of the high-nickel ternary precursor to lithium hydroxide is 100:105; the nickel-cobalt-manganese ternary precursor uses Ni 0.83 co 0.12 mn 0.05 (OH) 2 .

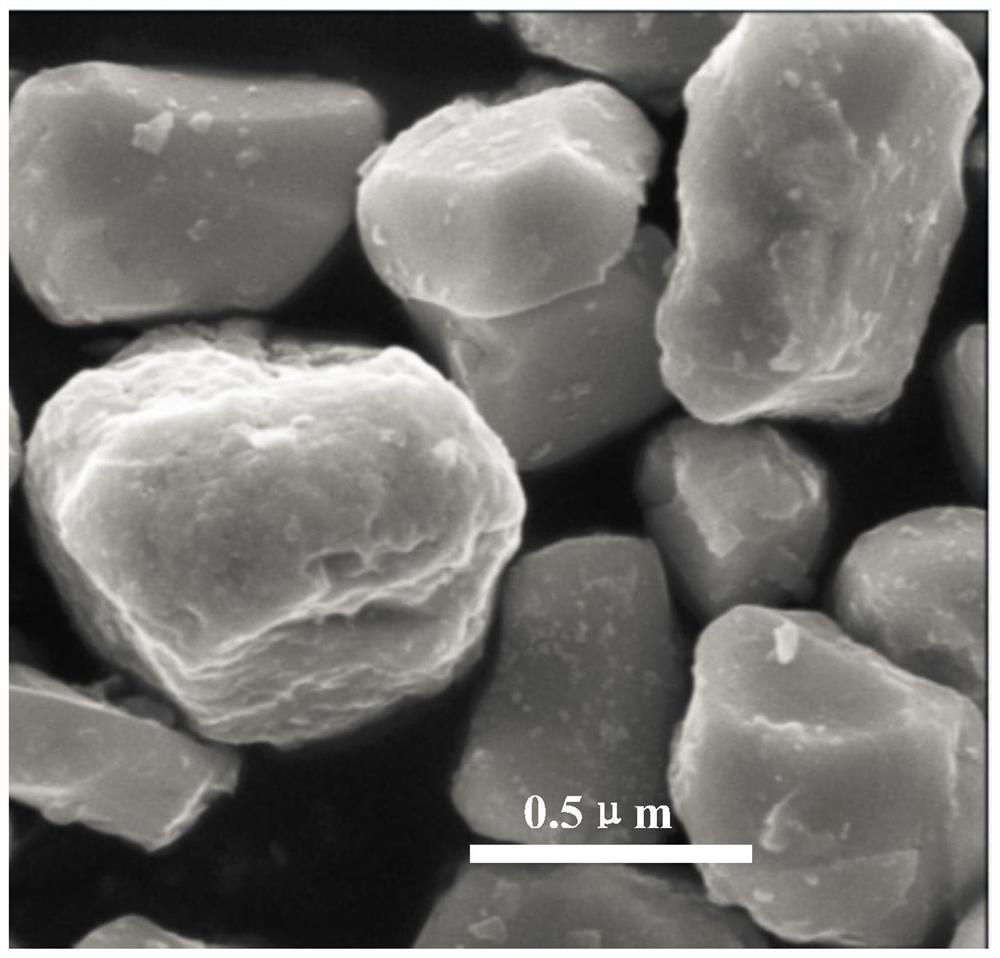

[0040]2) Pulverize the ternary positive electrode material after primary calcination to obtain powder A with a particle size of D50<1 μm; the specific steps of pulverization are as follows: first, carry out a selection wheel mill, and the particle size D50 is below 10 μm, and then pass th...

Embodiment 2

[0049] 1) Mix the high-nickel ternary precursor, lithium source and modification additives evenly for calcination. The sintering temperature rises to 230°C within 8 hours, and the temperature in the constant temperature section is 800°C for 15 hours to obtain oxidation modification. high-nickel ternary cathode material;

[0050] Among them, the total mass parts of the high-nickel ternary precursor and lithium hydroxide are 203 parts, and the modification additive is 0.005 parts by mass of TiO 2 , that is, the amount added is 5000ppm. The molar ratio of high nickel ternary precursor to lithium hydroxide is 100:103.

[0051] 2) Pulverize the ternary positive electrode material after primary calcination to obtain powder A with a particle size of D50<1 μm; the specific steps of pulverization are as follows: first, carry out a selection wheel mill, and the particle size D50 is below 10 μm, and then pass through the rollers and come out The particle size D50 of the powder is less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com