Modified AOD (Argon Oxygen Decarburization) slag as well as preparation method and application thereof and building material

A construction material and modification technology, applied in the field of metallurgy, can solve the problems of poor product safety and high leaching concentration of Cr element, and achieve the effects of low production cost, low leaching concentration and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of modified AOD slag, comprises the following steps:

[0026] Melt and mix AOD slag and fly ash to obtain molten slag;

[0027] The molten slag is quenched to obtain modified AOD slag.

[0028] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0029] The invention melts and mixes AOD slag and fly ash to obtain molten slag.

[0030] The present invention has no special limitation on the source of the AOD slag, and the AOD slag well-known to those skilled in the art can be used; Refining slag produced by refining. In the present invention, the water content of the AOD slag is preferably ≤5wt%, more preferably 2wt%. In the present invention, the chemical composition of the AOD slag preferably includes CaO 55-60wt%, more preferably 56-59wt%, further preferably 57-58wt%; SiO 2 25~30wt%, more preferably 26~29wt%...

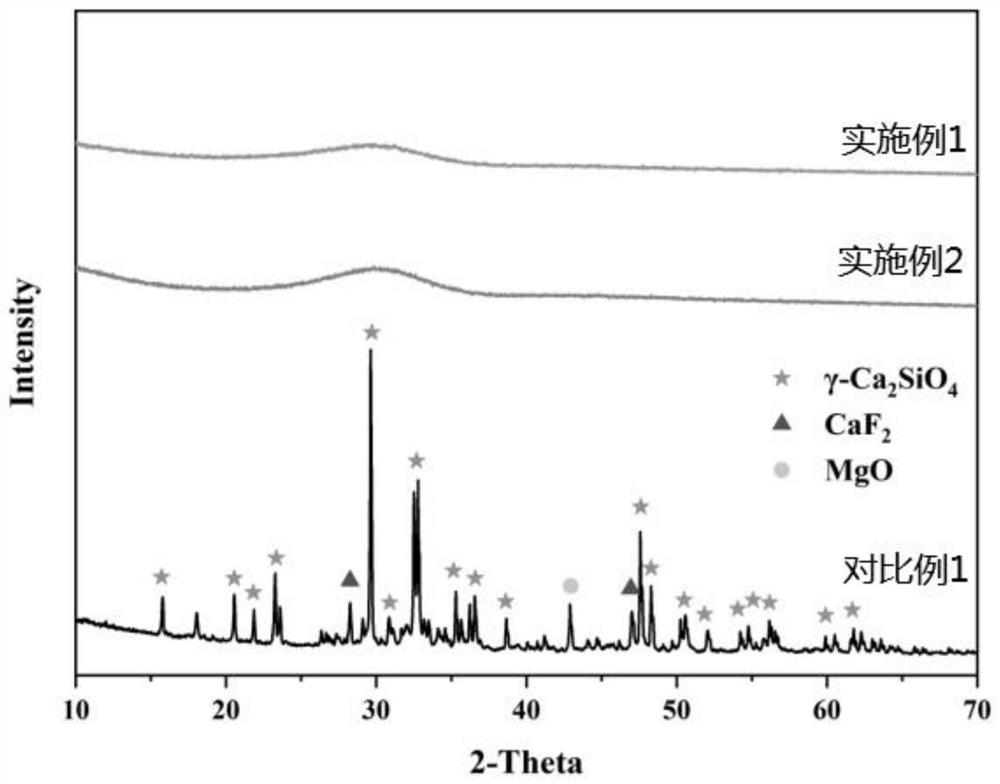

Embodiment 1

[0041] (1) Modified AOD slag

[0042] Mix 65g of AOD slag and 35g of fly ash evenly and place them in a corundum crucible, place the corundum crucible in a vertical resistance furnace, raise the temperature to 1550°C at a rate of 5°C / min, heat-preserve, melt and mix for 60min, and obtain a molten scum.

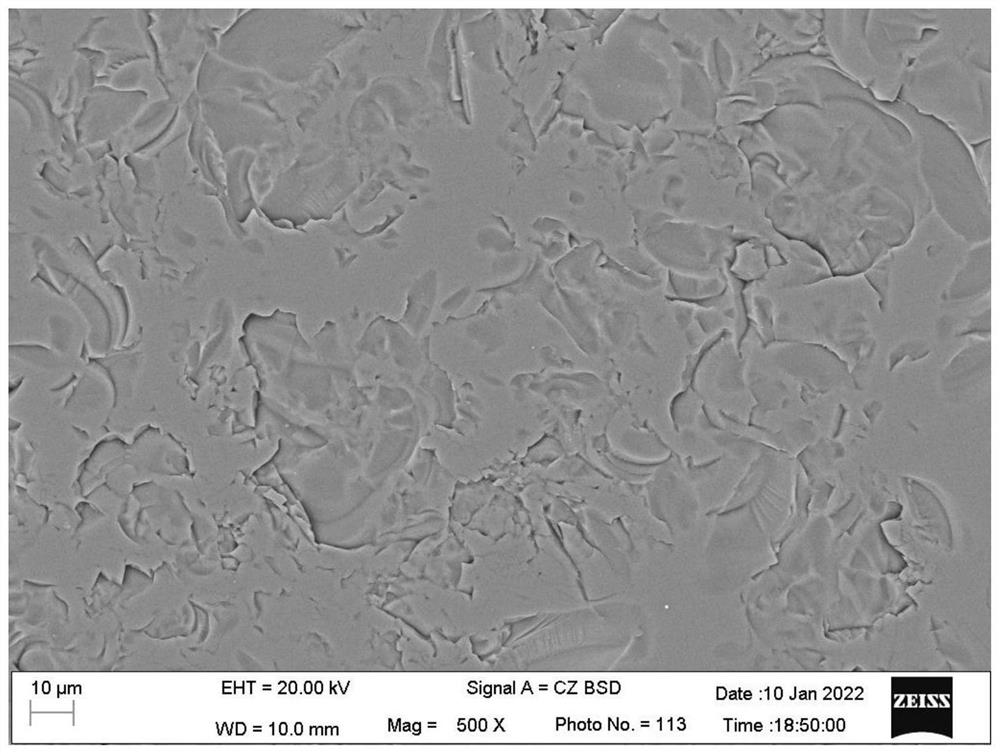

[0043] The corundum crucible was removed from the vertical resistance furnace, high-pressure water quenching was carried out at a cooling rate of 400° C. / min, and the obtained granulated slag was ground to obtain modified AOD slag with a particle size of 0.08 mm (specific surface area of 542 m 2 / kg), wherein, the water pressure of high pressure water quenching is 0.6MPa.

[0044] (2) Building materials

[0045] The modified AOD slag and Portland cement clinker are mixed at a mass ratio of 2:8 to obtain building materials.

Embodiment 2

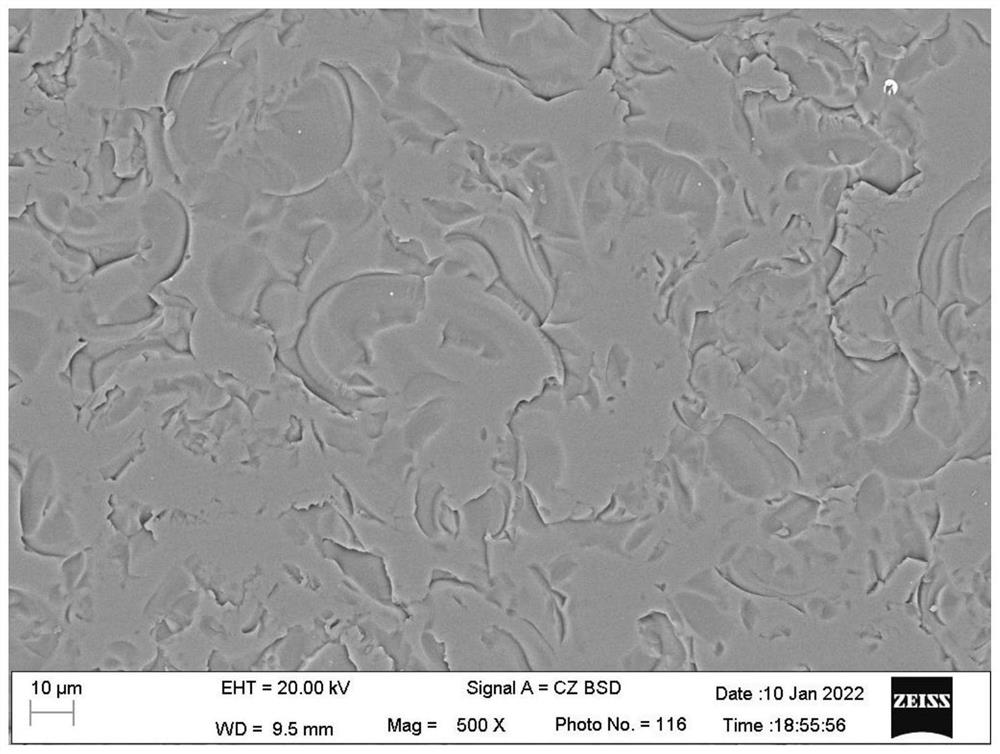

[0047] The modified AOD slag and building materials were prepared according to the method of Example 1, the difference from Example 1 was that the amount of AOD slag was 70g, and the amount of fly ash was 30g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com