Pretreatment method of machine-made sand and concrete containing machine-made sand

A technology for pretreatment and machine-made sand, applied in the field of machine-made sand, can solve the problems of decreased workability of concrete mixture construction, reduced strength and durability of concrete, and inability to fully bond concrete, etc., to improve internal strength and compactness , The effect of reducing the mud content, improving the strength and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

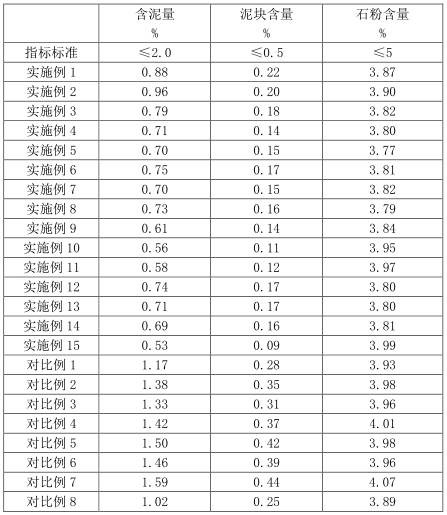

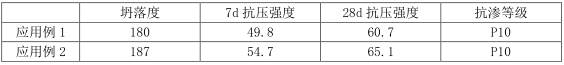

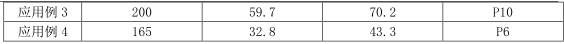

Examples

Embodiment 1

[0044] This embodiment discloses a kind of machine-made sand, the machine-made sand is machine-made sand obtained through pretreatment, and the pretreatment method of the machine-made sand specifically includes the following steps:

[0045] Step 1, crushing and screening pretreatment:

[0046] Step 1-1, collecting 400kg of limestone tailings and sending them into a jaw crusher for coarse crushing to obtain coarse sand with an average particle size of 30-35mm;

[0047] Step 1-2, sending the obtained coarse sand into an impact crusher for fine crushing to obtain medium sand with an average particle size of 25-30 mm;

[0048] Step 1-3, add the medium sand into the water elutriation machine for elutriation, put the medium sand washed twice into the drying room, and dry at room temperature 60°C for 6 hours;

[0049] Step 2, modification treatment:

[0050] Step 2-1, preparation of modifying agent: 80kg of water, 30kg of polyacrylic acid solution, 25kg of mercaptopropionic acid, 20k...

Embodiment 2

[0054] A kind of pretreatment method of machine-made sand, differs from embodiment 1 in that: the content of each component and process parameter are different in the treatment process, specifically as follows:

[0055] Step 1-1, collecting 450kg of limestone tailings;

[0056] Step 2-1, preparation of modifying agent: 100kg of water, 35kg of polyacrylic acid solution, 30kg of mercaptopropionic acid, 25kg of hydroxyethylidene diphosphonic acid, 7kg of dissociating agent and 5kg of penetrating agent are mixed, and the temperature is Stir at 65° C. for 8 minutes at a rotational speed of 100 r / min to obtain a modifier; use urea powder as a dissociating agent and n-butanol as a penetrating agent.

[0057] Step 2-2: Add the modifier to the medium sand, stir at 55°C and 70r / min for 25min, keep it at 35°C for 5.5h, then wash with deionized water and dry in vacuum Drying at a constant temperature at 75°C for 1 hour; sieving the dried medium sand with an ultrasonic vibrating screen at...

Embodiment 3

[0059] A kind of pretreatment method of machine-made sand, differs from embodiment 1 in that: the content of each component and process parameter are different in the treatment process, specifically as follows:

[0060] Step 1-1, collecting 425kg of limestone tailings;

[0061] Step 2-1, preparing modifier: mix 90kg of water, 32.5kg of polyacrylic acid solution, 27.5kg of mercaptopropionic acid, 22.5kg of hydroxyethylidene diphosphonic acid, 6kg of dissociating agent and 4kg of penetrant; The dissociating agent is urea powder, and the penetrating agent is prepared by mixing 2 kg of n-butanol and 2 kg of fatty alcohol polyoxyethylene ether, that is, the mass ratio of n-butanol and fatty alcohol polyoxyethylene ether in the penetrating agent is 1:1.

[0062] In step 2-2, the dried medium sand is sieved by an ultrasonic vibrating sieve at a frequency of 21 kHz to obtain modified sand with an average particle size of 15-25 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com