Method for preparing oxygen by using lunar soil through hydrogen reduction-electrolysis method

An electrolysis and oxygen technology, applied in the field of metallurgy, can solve the problem of inability to extract oxygen, achieve the effects of low cost, strong oxidation resistance and corrosion resistance, and improve current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

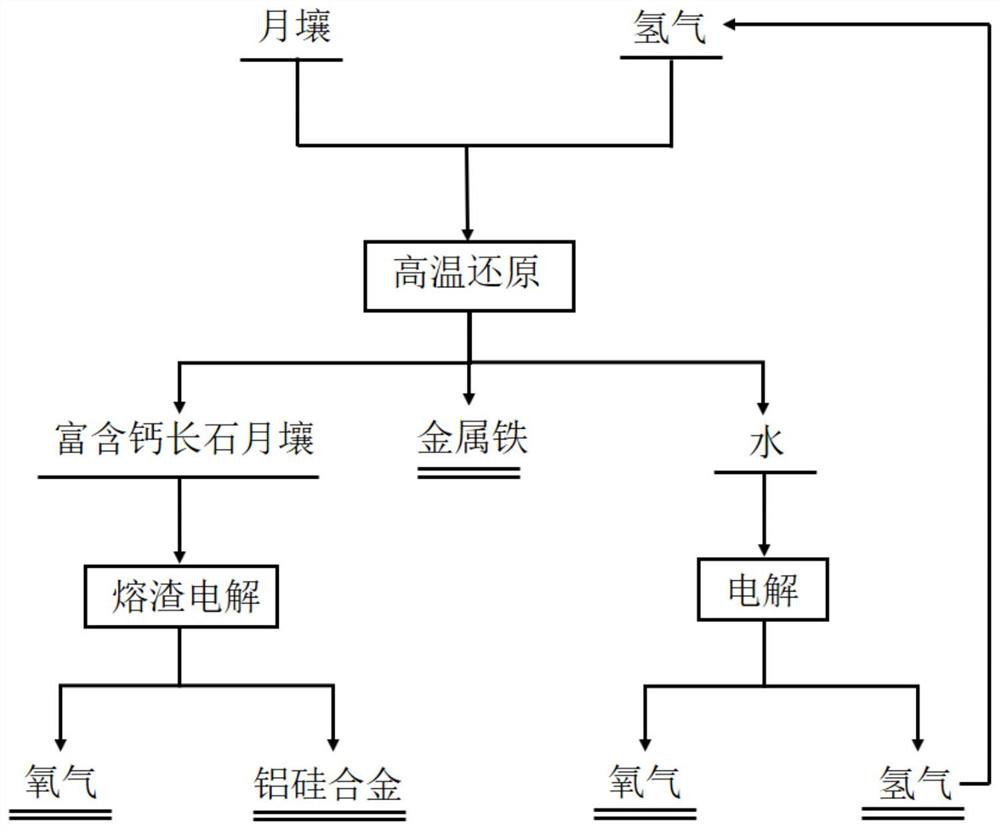

[0030] The process of hydrogen reduction-electrolysis method for producing oxygen from lunar soil is as follows: figure 1 As shown, the specific steps are as follows: the chemical composition of lunar soil used in this embodiment is 43.56% SiO by mass fraction 2 , 24.52% Al 2 o 3 , 8.36% FeO, 12.74% CaO, 4.13% MgO, 6.46% TiO 2 , 0.22%K 2 O, the balance is impurities.

[0031] S1. Put 50g of lunar soil into a closed reactor and raise the temperature to 900°C under vacuum;

[0032] S2. Introduce hydrogen into the reactor at a rate of 150mL / min, and keep it warm for 6 hours to produce metallic iron and anorthite-rich lunar soil, and condense to obtain another product water; and condense to obtain The water is electrolyzed to produce hydrogen and oxygen;

[0033] S3. Put the anorthite-rich lunar soil separated from the metal iron into an electrolytic cell with graphite as the cathode and iridium-tungsten alloy as the anode, and raise the temperature to 1550°C to melt the lun...

Embodiment 3

[0040] S1. Put 50g of lunar soil into a closed reactor and raise the temperature to 1250°C under vacuum conditions; among them, the chemical composition of lunar soil is 46.95% SiO by mass fraction 2 , 22.47% Al 2 o 3 , 5.14% FeO, 11.38% CaO, 5.34% MgO, 8.27% TiO 2 , 0.43%K 2 O, the balance is impurities.

[0041] S2. Introduce hydrogen gas at a rate of 250mL / min into the reactor and keep it warm for 2 hours to produce metallic iron and anorthite-rich lunar soil, and condense to obtain another product water, which is electrolyzed to prepare hydrogen and oxygen ;

[0042]S3. Put the anorthite-rich lunar soil separated from the metallic iron into the electrolytic cell, and raise the temperature to 1650°C to melt the lunar soil into liquid slag;

[0043] S4. Using graphite as the cathode and iridium-tungsten alloy as the anode, control the current density of the electrolytic cell to be constant at 1.0A / cm 2 , the contact surface area between the anode of the electrolytic ce...

Embodiment 4

[0046] S1. Put 50g of lunar soil into a closed reactor and raise the temperature to 950°C under vacuum; among them, the chemical composition of lunar soil is 49.25% SiO by mass fraction 2 , 18.61% Al 2 o 3 , 12.83% FeO, 10.2% CaO, 7.87% MgO, 0.86% TiO 2 , 0.37%K 2 O, the balance is impurities.

[0047] S2. Introduce hydrogen at a rate of 200mL / min into the reactor and keep it warm for 3 hours to prepare metallic iron and anorthite-rich lunar soil, and condense to obtain another product water, and electrolyze the condensed water to prepare hydrogen and oxygen;

[0048] S3. Put the anorthite-rich lunar soil separated from the metallic iron into the electrolytic cell, and raise the temperature to 1600°C to melt the lunar soil into liquid slag;

[0049] S4. Using graphite as the cathode and iridium-tungsten alloy as the anode, control the current density of the electrolytic cell to be constant at 0.8A / cm 2 , the contact surface area between the anode of the electrolytic cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com