Preparation method and application of zero-valent copper modified reinforced zero-valent iron-carbon micro-electrolysis material

An iron-carbon micro-electrolysis and micro-electrolysis technology, applied in the field of environmental governance, can solve the problems of limited degradation ability of pollutants, prone to agglomeration, and difficult to reuse, so as to promote the process of electron transfer, facilitate popularization and application, and improve corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

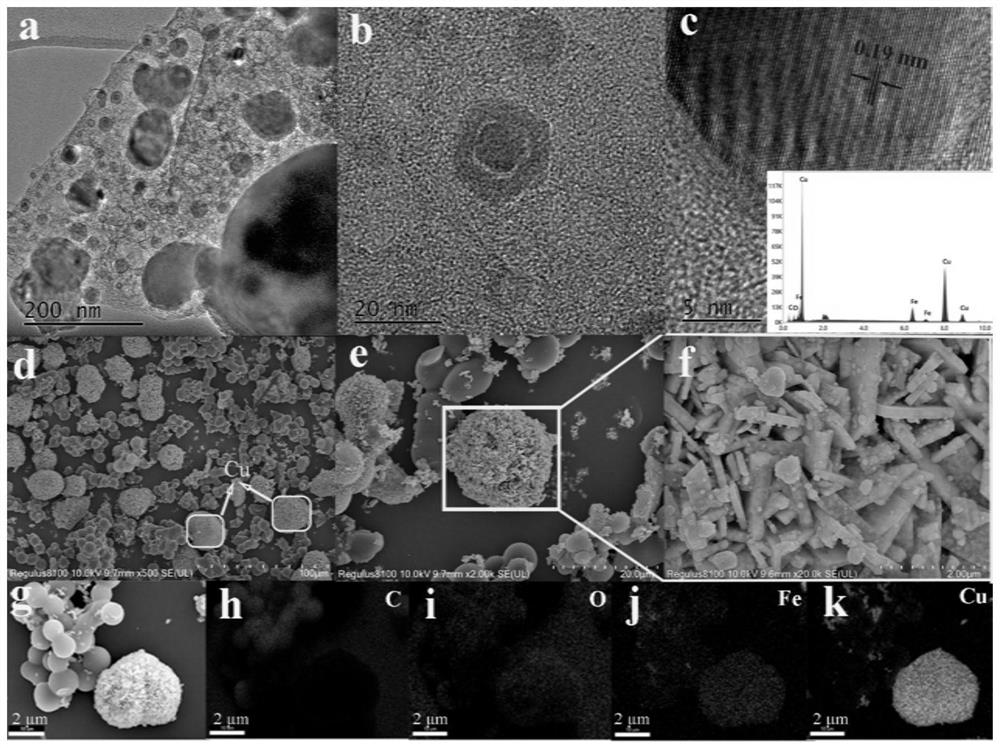

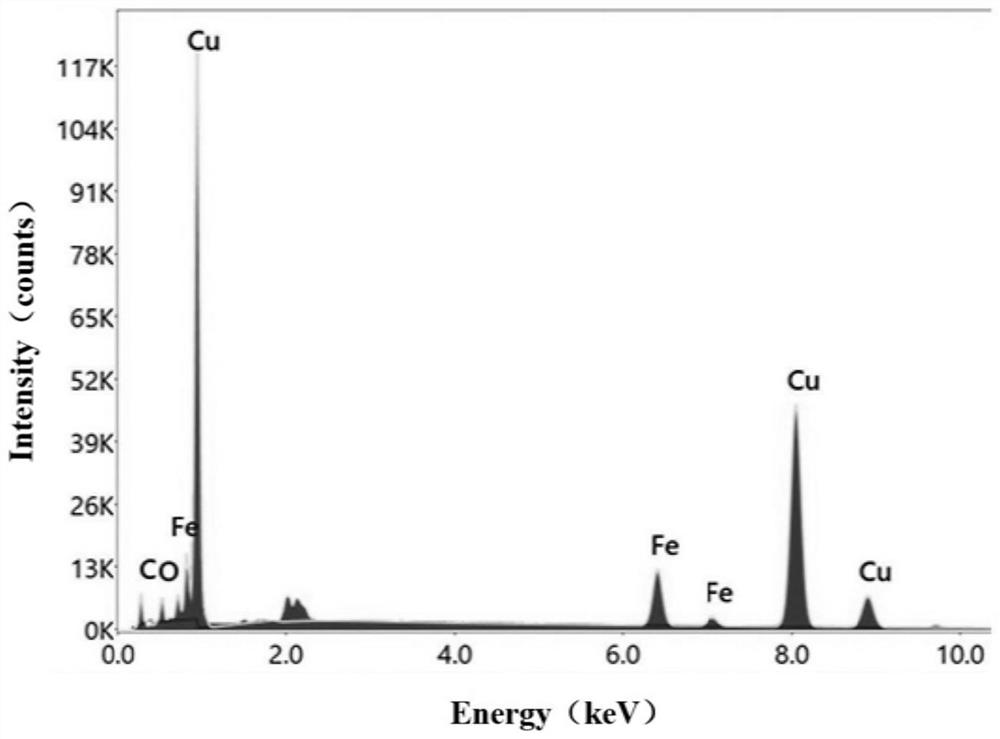

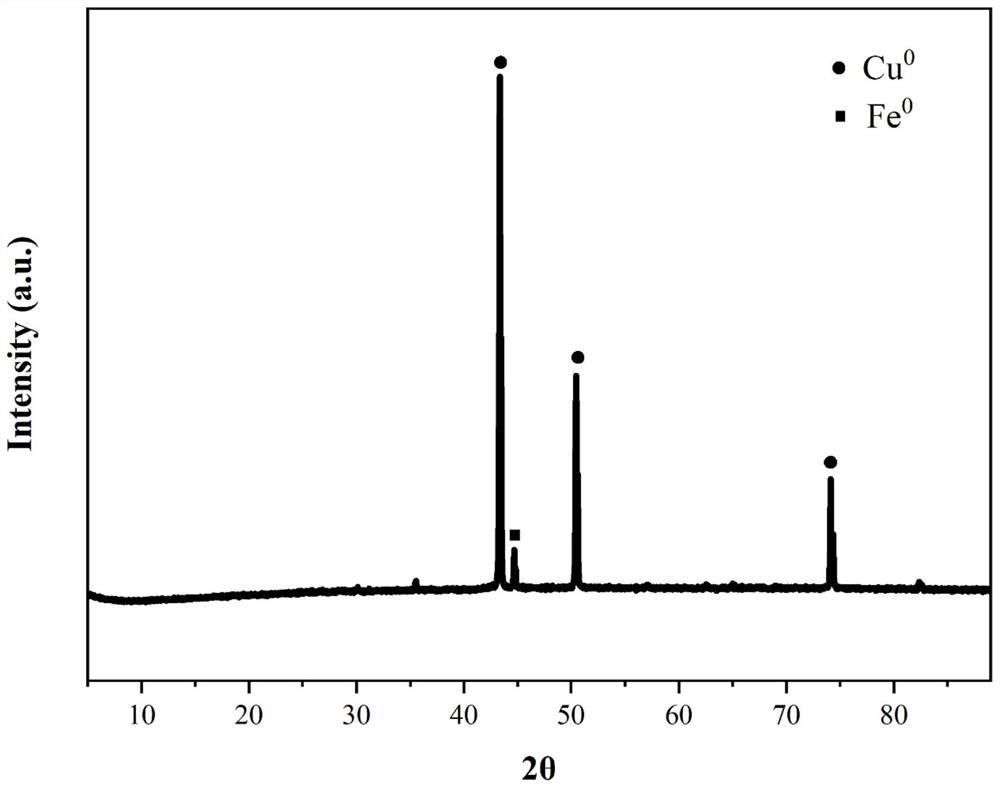

[0035] A method for preparing nano-zero-valent copper modified and enhanced nano-zero-valent iron-carbon-copper micro-electrolytic material, comprising the following steps:

[0036] 1) Fe 0Preparation of / C micro-electrolysis materials: using ferric citrate as iron source and glucose as carbon source to prepare carbon sphere-coated Fe 0 composite material. Specifically, a certain quality of glucose and ferric citrate was added to a 120mL beaker containing 80mL of ultrapure water to ensure that the molar ratio of iron to carbon was 1:22. Keep the temperature at 180°C for 10 hours, cool it to room temperature, wash it with water and ethanol three times, and dry it for later use. The product is an iron-carbon micro-electrolysis material precursor.

[0037] 2) Fe 0 / C@Cu 0 Preparation of micro-electrolytic materials: using basic copper carbonate as the copper source, iron-carbon micro-electrolytic material precursors as raw materials, and preparing Fe by high-temperature calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com