Method for dealkalizing red mud and co-producing sodium salt

A technology of sodium salt and red mud, applied in the directions of alkali metal carbonate, chemical instruments and methods, alkali metal sulfite/sulfite, etc., can solve the problems of complicated operation and difficult control of required conditions, and achieve simple operation. , equipment requirements and reaction conditions require low and high dealkalization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

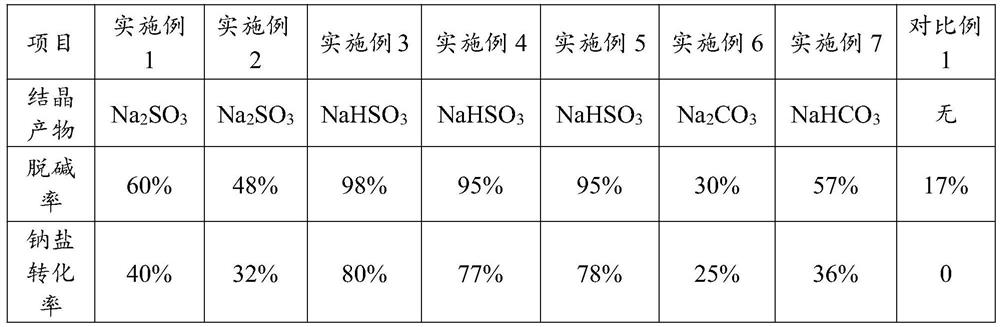

Examples

Embodiment 1

[0045] 1kg red mud powder (of which Na 2 The mass of O is 10%, the particle size is 0.5~200 μm) and 0.1L water are mixed, stirred for 30min, obtains the red mud slurry, at 20 ℃, is passed into the sulfur dioxide of 40L / kg red mud in the described red mud slurry until The pH value of the red mud slurry is 9-10, acidification treatment is carried out for 0.5h, and the stratification is carried out for 12h, and the solid-liquid separation is carried out to obtain the sodium salt solution, and the sodium salt solution is cooled to 0°C to precipitate the sodium salt crystallization Liquid separation, joint production to obtain sodium salt.

Embodiment 2

[0047] The difference from Embodiment 1 is that the red mud slurry is obtained by mixing 1 kg of red mud powder and 10 L of water, and the rest of the content is consistent with that of Embodiment 1.

Embodiment 3

[0049] The difference from Embodiment 1 is that sulfur dioxide is introduced into the red mud slurry for acidification treatment until the pH value of the red mud slurry is 5-6, and the rest of the content is consistent with that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com