Method for purifying lactide

A lactide and solvent technology, applied in organic chemistry methods, organic chemistry, etc., can solve the problems of multiple operation steps and high processing temperature, reduce impurities such as m-lactide, improve product purity, and ensure product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of crude L-lactide: Using zinc oxide and stannous octoate as catalysts, 88% L-lactic acid as raw material, after dehydration, polycondensation and depolymerization of lactic acid, crude L-lactide with a purity of 85.6% was obtained. in, m -The lactide content is 5.8%, the lactic acid content is 5.4%, the lactic acid dimer and trimer content is 2.3%, and a small amount of water and other impurities are also included.

[0039] Take 200g of the above-mentioned crude lactide, use a crusher to crush it to a diameter of 0.5-1.0mm, add it to the reaction kettle at one time, then add 200g of deionized water, keep the system temperature at 5°C, stir at 200rpm for 5min, and then add 100 g of absolute ethanol was added therein, the reaction temperature was maintained at 5° C., and the reaction was continued to stir for 10 minutes, then filtered, washed with water, and dried at 70° C. for 8.0 hours to obtain purified L-lactide. As a result of testing, the product has a...

Embodiment 2

[0041] Preparation of L-lactide: Zinc oxide and stannous octoate are used as catalysts, 88% L-lactic acid is used as raw material, after lactic acid dehydration, polycondensation and depolymerization reactions, lactide with a purity of 79.0% is obtained. in, m -The content of lactide is 6.2%, the content of lactic acid is 6.7%, the content of lactic acid dimer and trimer is 3.1%, and also includes a small amount of water and other impurities.

[0042] Take 200g of the above-mentioned crude lactide, use a crusher to crush it to a diameter of 0.5-1.0mm, add it to the reaction kettle at one time, then add 60g of deionized water, keep the system temperature at 10°C, stir at 100rpm for 3min, and then add 120 g of absolute ethanol was added therein, the reaction temperature was maintained at 15° C., and the reaction was continued to stir for 30 minutes, then filtered, washed with water, and dried at 70° C. for 8 hours to obtain purified L-lactide. As a result of testing, the produc...

Embodiment 3

[0044] Preparation of L-lactide: Zinc oxide and stannous octoate are used as catalysts, 88% L-lactic acid is used as raw material, after dehydration, polycondensation and depolymerization of lactic acid, lactide with a purity of 90.0% is obtained. in, m -The content of lactide is 3.7%, the content of lactic acid is 3.4%, the content of lactic acid dimer and trimer is 1.9%, and also includes a small amount of water and other impurities.

[0045] Take 200g of the above-mentioned crude lactide, crush it with a crusher to a diameter of 0.5-1.0mm, add it to the reaction kettle at one time, then add 600g of deionized water, keep the system temperature at 2°C, and stir at 300rpm for 5min. Then 150 g of absolute ethanol was added thereto, the reaction temperature was maintained at 2° C., and the reaction was continued to stir for 5 minutes, then filtered, washed with water, and dried at 70° C. for 8 hours to obtain purified L-lactide. As a result of testing, the product has a chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

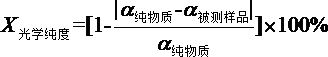

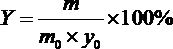

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com