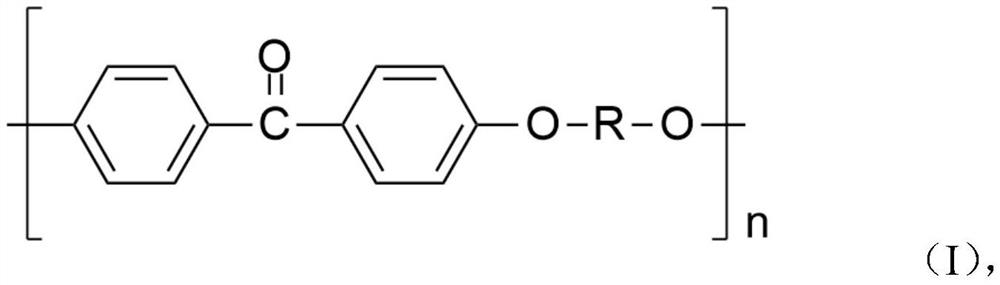

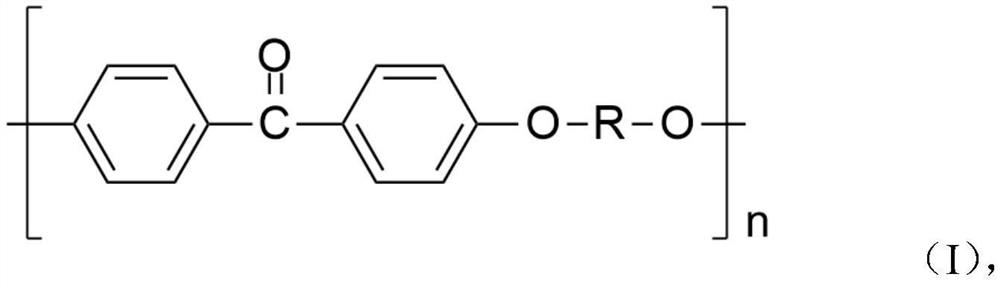

Polyaryletherketone containing naphthalene structure and preparation method thereof

The technology of polyaryletherketone and naphthalene diphenol is applied in the field of polyaryletherketone containing naphthalene structure and its preparation, high-performance engineering plastics synthesis, and can solve the problems of insolubility, difficulty in handling, low glass transition temperature and the like, To achieve the effect of easy processing, wide application prospects and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] According to one embodiment of the present invention, the preparation method of the polyaryletherketone includes adding the naphthalene diol monomer, 4,4'-dihalobenzophenone monomer and catalyst into an aprotic polar Azeotropic dehydration in a solvent or a mixed solvent containing an aprotic polar solvent, followed by a polymerization reaction, adding a precipitating agent after the reaction to precipitate the polymer, and finally filtering, washing and drying.

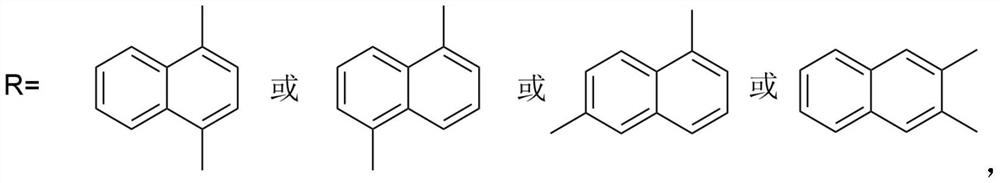

[0042] In a further embodiment, the naphthalene diol monomer is at least A sort of.

[0043] In a further embodiment, the 4,4'-dihalobenzophenone monomer is selected from 4,4'-difluorobenzophenone, 4,4'-dichlorobenzophenone, 4, At least one of 4'-dibromobenzophenone and 4,4'-diiodobenzophenone.

[0044] In a further embodiment, the aprotic polar solvent is preferably selected from N,N'-dimethylformamide, N,N'-dimethylacetamide, sulfolane, N-methylpyrrolidone, dimethyl at least one of sulfoxides.

[0045] I...

Embodiment 1

[0055] Under nitrogen protection, 192.2g (1.2mol) 1,4-naphthalenediol, 261.6g (1.2mol) 4,4'-difluorobenzophenone, 248.8g (1.8mol) anhydrous K 2 CO 3 , 1600ml of N-methylpyrrolidone and 400ml of toluene were added to a reactor equipped with a stirrer, a thermometer, a reflux water separator and a nitrogen inlet, and the temperature was raised while stirring to react. Then, most of the toluene was distilled off. The temperature was raised to 200°C, and the high-temperature polymerization was carried out for 20 hours. The reaction system gradually changed from light yellow to brown, and the viscosity of the system increased significantly. After the reaction is finished, N-methylpyrrolidone is added to dilute the reaction mixture, the polymer solution is stirred at high speed, and boiling water is used as a precipitating agent to precipitate, filter and drain the polymer. The polymer was vacuum-dried at 120° C. for 24 hours to obtain a pure polyaryletherketone resin.

[0056] T...

Embodiment 2

[0058] Under nitrogen protection, 192.2g (1.2mol) 1,5-naphthalenediol, 261.6g (1.2mol) 4,4'-difluorobenzophenone, 248.8g (1.8mol) anhydrous K 2 CO 3 , 1600ml of N-methylpyrrolidone and 400ml of toluene were added to a reactor equipped with a stirrer, a thermometer, a reflux water separator and a nitrogen inlet, and the temperature was raised while stirring to react. Then, most of the toluene was distilled off. The temperature was raised to 200°C, and the high-temperature polymerization was carried out for 15 hours. The reaction system gradually changed from light yellow to brown, and the viscosity of the system increased significantly. After the reaction is finished, N-methylpyrrolidone is added to dilute the reaction mixture, the polymer solution is stirred at high speed, and boiling water is used as a precipitating agent to precipitate, filter and drain the polymer. The polymer was vacuum-dried at 120° C. for 24 hours to obtain a pure polyaryletherketone resin.

[0059] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com