Photo-thermal phase change energy storage material as well as preparation method and application thereof

A phase change energy storage material and a phase change material technology, applied in the field of photothermal phase change energy storage materials and their preparation, can solve the problems of low photothermal conversion efficiency, single function, easy agglomeration of photosensitizers, etc., and achieve enhanced heat storage. performance and cycle stability, avoidance of agglomeration, effect of shortening heat transfer paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing a MOF-based photothermal phase change energy storage material with photothermal conversion performance, the method comprising the steps of:

[0052] (1) MIL-101(Cr) was synthesized by one-step hydrothermal method: first, 1.44g (8.0mmol) 2-aminoterephthalic acid (H2BDC-NH2), 3.20g (8.0mmol) Cr(NO3) 3 9H2O and 0.80 g (20.0 mmol) NaOH were dissolved in 60 mL of deionized water, stirred at room temperature for 30 min; then the mixed solution was transferred to a Teflon-lined autoclave, and reacted at 180 °C for 12 h. Finally, the solid product was purified multiple times using N-N dimethylformamide, methanol, and deionized water, respectively. The centrifuged solid product was dried in a vacuum oven at 100 °C for 24 h to obtain MOF powder.

[0053] Metal-organic framework matrix MIL-101(Cr) adsorbed phase change materials: dry the MOF powder in step (1) in a vacuum oven at 80°C for 24 hours to fully activate and open pores; take 1.0g of vacuum-dried ...

Embodiment 2

[0058] The difference from the preparation method in Example 1 is that the addition amount of pyrrole monomer is 5 mL, and ODA@MOF / PPy-5 is obtained.

[0059] The enthalpy value of the MOF-based photothermal phase change energy storage material ODA@MOF / PPy-5 prepared in this example is 130.85J / g, and the photothermal conversion efficiency can reach up to 85.6%. The results of the anti-leakage test show that the phase There is hardly any leakage when the variable composite material is treated in an oven at 80°C for 1 hour.

Embodiment 3

[0061] The difference from the preparation method in Example 1 is that the addition amount of pyrrole monomer is 6mL to obtain ODA@MOF / PPy-6.

[0062] The enthalpy value of the MOF-based photothermal phase change energy storage material ODA@MOF / PPy-6 prepared in this example is 129.58J / g, and the photothermal conversion efficiency can reach up to 88.3%. The results of the anti-leakage test show that the phase There is hardly any leakage when the variable composite material is treated in an oven at 80°C for 1 hour.

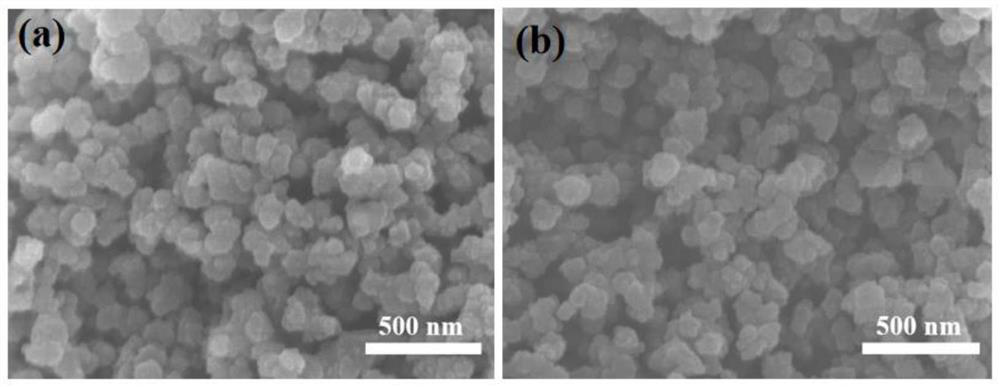

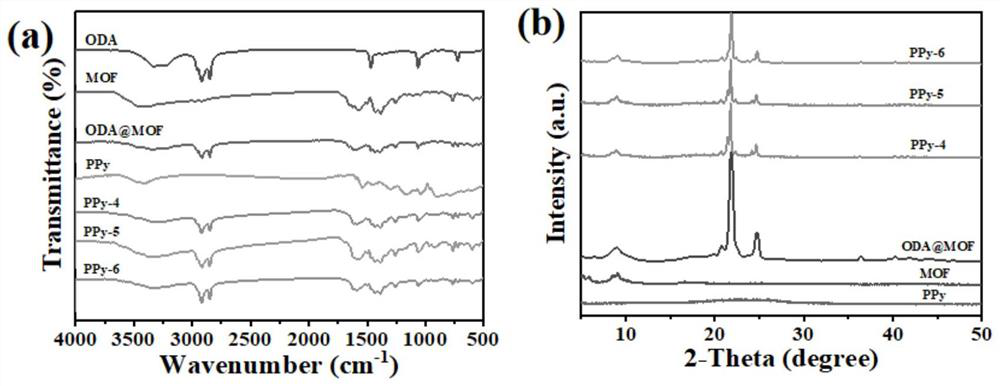

[0063] The SEM image of the ODA@MOF / PPy-6 of the MOF and the composite material in this example 3 is as follows figure 1 Shown are the morphologies of MOF and ODA@MOF / PPy-6 at the same magnification. Compared with pristine MOF, ODA@MOF / PPy-6 exhibits a larger size due to the coating effect of PPy particle polymer on the surface of ODA@MOF.

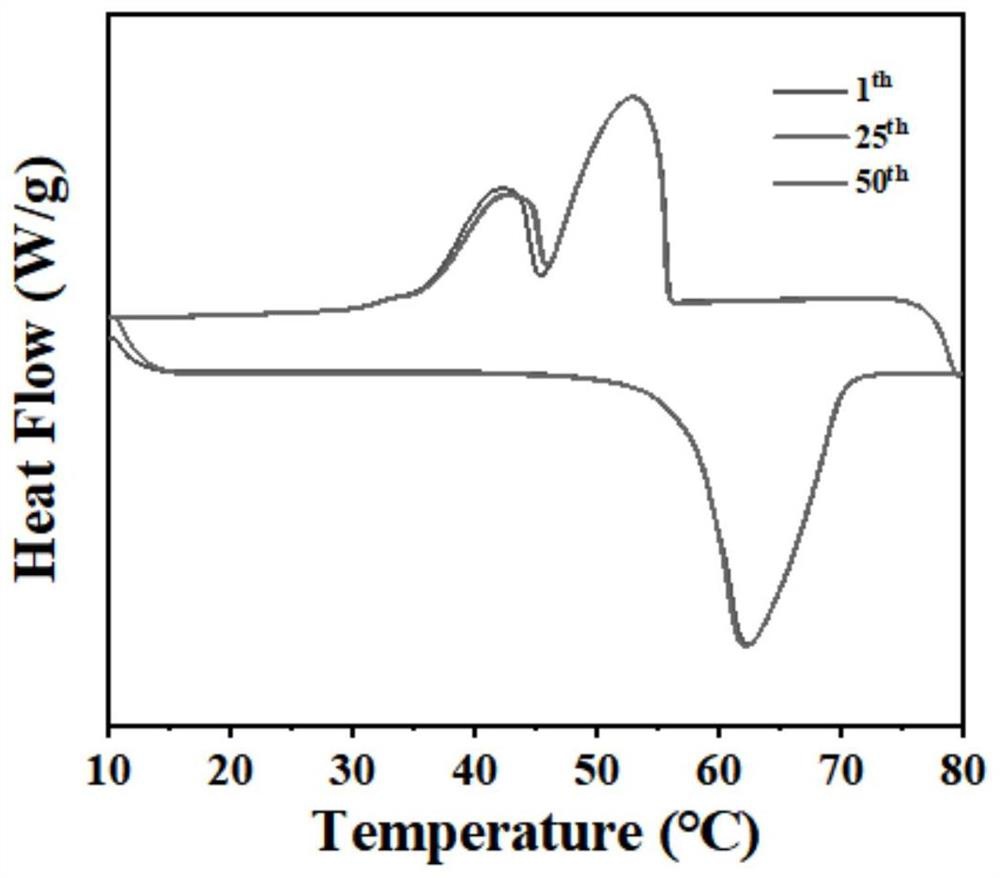

[0064] The DSC cycle curve of ODA@MOF / PPy-6 of this embodiment 3 through ODA@MOF / PPy-6 is as follows figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com