Method for preparing cellulose microfibril film from wheat straw

A technology of cellulose microfibrils and wheat straw is applied in the post-treatment of cellulose pulp, post-treatment and modification of cellulose pulp, and cellulose treatment with microorganisms/enzymes. It can solve the potential value of waste of straw, the backward comprehensive utilization technology, problems such as low utilization rate of fine processing, to achieve the effect of efficient utilization, promoting market-oriented development and utilization, and improving the benefits of comprehensive agricultural utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

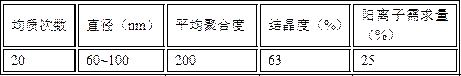

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be fully described below in conjunction with the embodiments of the present invention, and the described embodiments are only some of the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0015] One, embodiment one.

[0016] The method for preparing cellulose microfibrils and films thereof from wheat straw comprises the following steps:

[0017] 1. Screening treatment of wheat straw fiber slurry: Use IMC MT2110-086 CF Dynamic Drainage Tester (DDJ) to sieve the wheat straw fiber raw material. The speed is 1200r / min, stir until the filtrate is clear, collect the fine fiber components (P200) in the filtrate and the longer fiber components (R200) left on the screen, balance the water, and set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com