Fabricated airport pavement construction quality detection system and method based on BIM and TSL

A detection system and construction quality technology, applied in the direction of measuring devices, optical devices, data processing applications, etc., can solve the problems of many construction constraints, manual rough measurement, slow construction progress, etc., to reduce assembly errors or project delays, Achieve construction efficiency and construction quality, improve accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

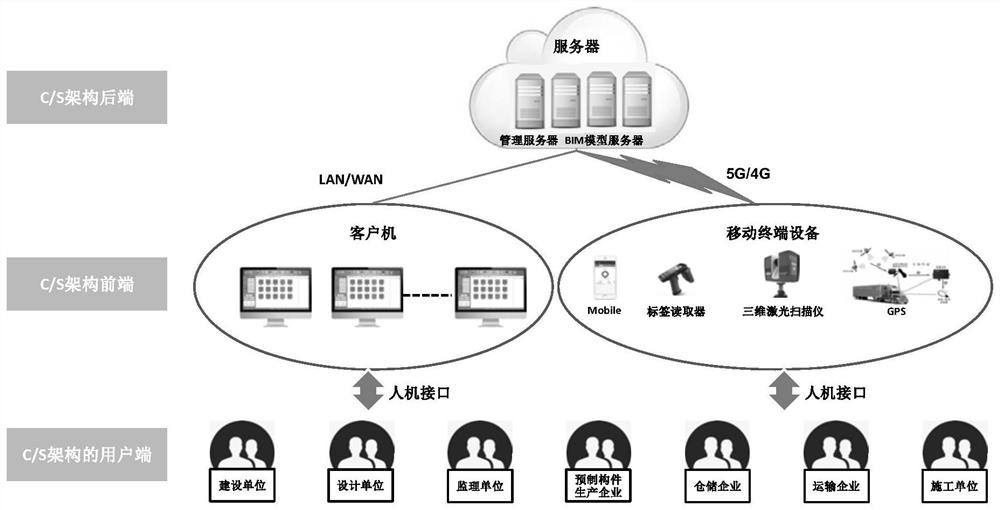

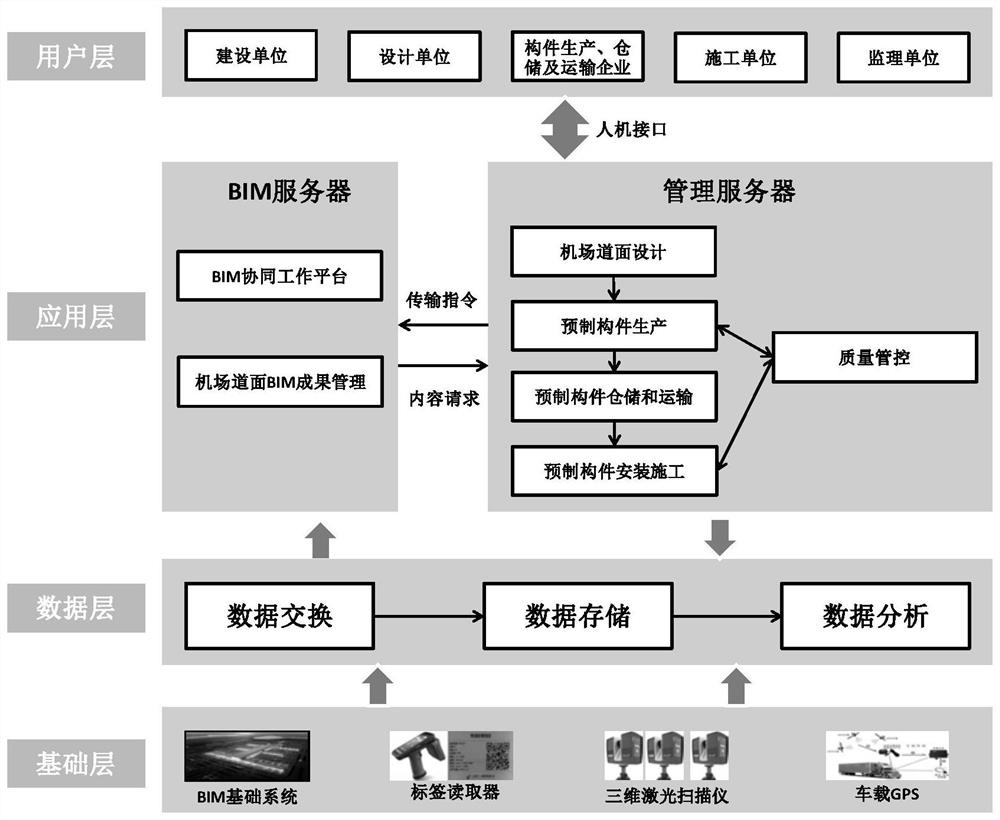

[0061] combine Figure 1 to Figure 5 , a prefabricated airport pavement construction quality inspection system and method based on BIM and TSL, including a service system, the service system is adapted to a logical framework application system, and construction management and quality control are carried out through construction management methods and quality inspection methods; The service system includes a server assembly, multiple client computers and a number of mobile terminal devices, and the server assembly includes a management server and at least one BIM model server.

[0062] The client accepts the user's request, and makes a request to the server assembly through the wired network to operate the database; the server assembly accepts the client's request, submits the data to the client, and the client calculates the data and presents the result to the The user; the mobile terminal device is connected to the server assembly through the 5G / 4G network; the mobile termina...

Embodiment 2

[0072] In the quality control of the quality control module in embodiment 1, adopt quality control method to monitor, described quality control method comprises as follows:

[0073] Step A1, the prefabricated airport pavement construction quality inspection system and method based on BIM and TSL are required;

[0074] Step A2: Inspect the quality management of factory component prefabrication and on-site component assembly for quality control, use 3D laser scanning technology to collect and store a large amount of quality-related data, and conduct statistical analysis and analysis of quality information according to quality standards Feedback in time to achieve quality control of components and ensure that component products and assembly as a whole meet the delivery standards;

[0075] Step A3, strengthen the quality management of prefabricated component manufacturers, ensure that all accessories can be accurately installed on site without errors and collisions, and meet the q...

Embodiment 3

[0081] The prefabricated airport pavement construction quality inspection system and method based on BIM and TSL, including a service system, the service system is adapted with a logical framework application system, and the management and control of construction production is carried out through the construction management method. The construction management method includes:

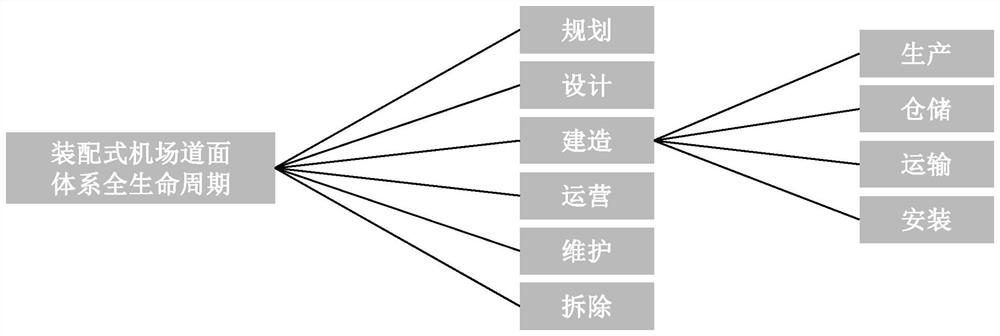

[0082] Production stage: This stage is the beginning of construction management. First, the version and information integrity of the model sent by the designer are checked. After passing, the model data conversion is required, and the design stage model is converted into the construction management model to complete the data conversion. Afterwards, the system will automatically extract the data information of the construction management model, analyze and generate the number ID and related attribute information of the unique identification number of the assembly component, and use the number ID informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com