Preparation method of esterified cellulose loaded MXene high-toughness film

A technology of esterifying cellulose and high toughness is applied in the field of preparation of cellulose film, which can solve the problems of complex preparation process, no economic benefit, and no wear resistance, flexibility and foldability of the film, and achieves high performance. Economic benefits, good water stability, the effect of simplifying the preparation and processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

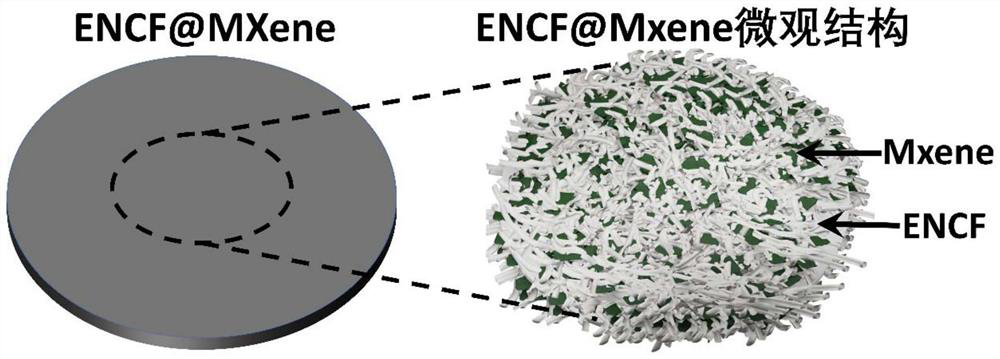

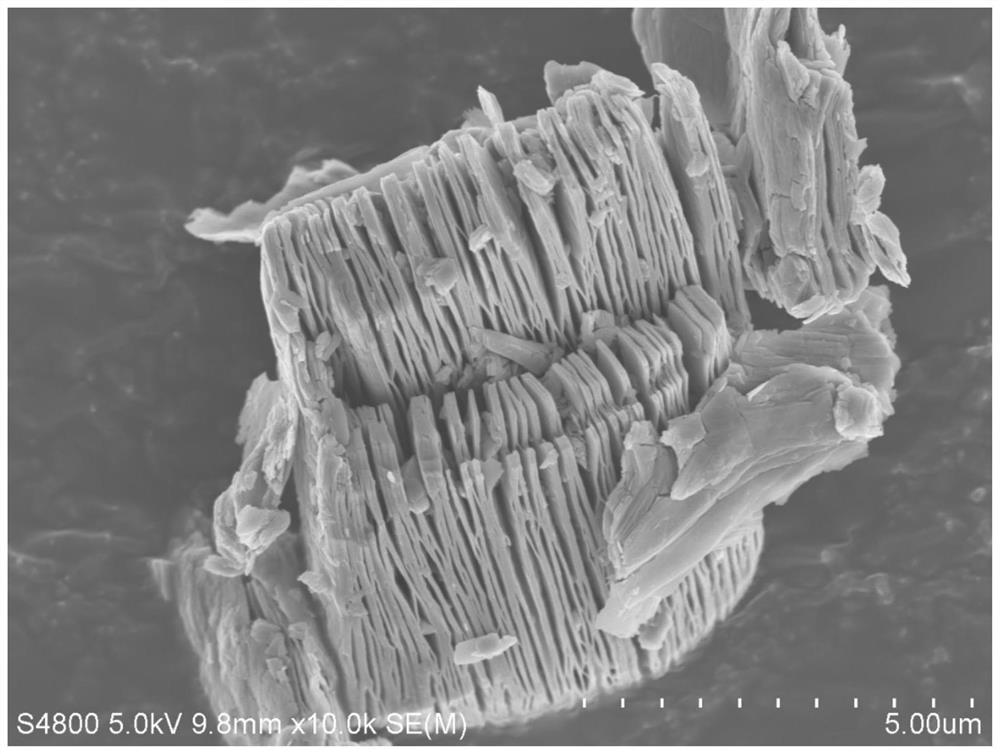

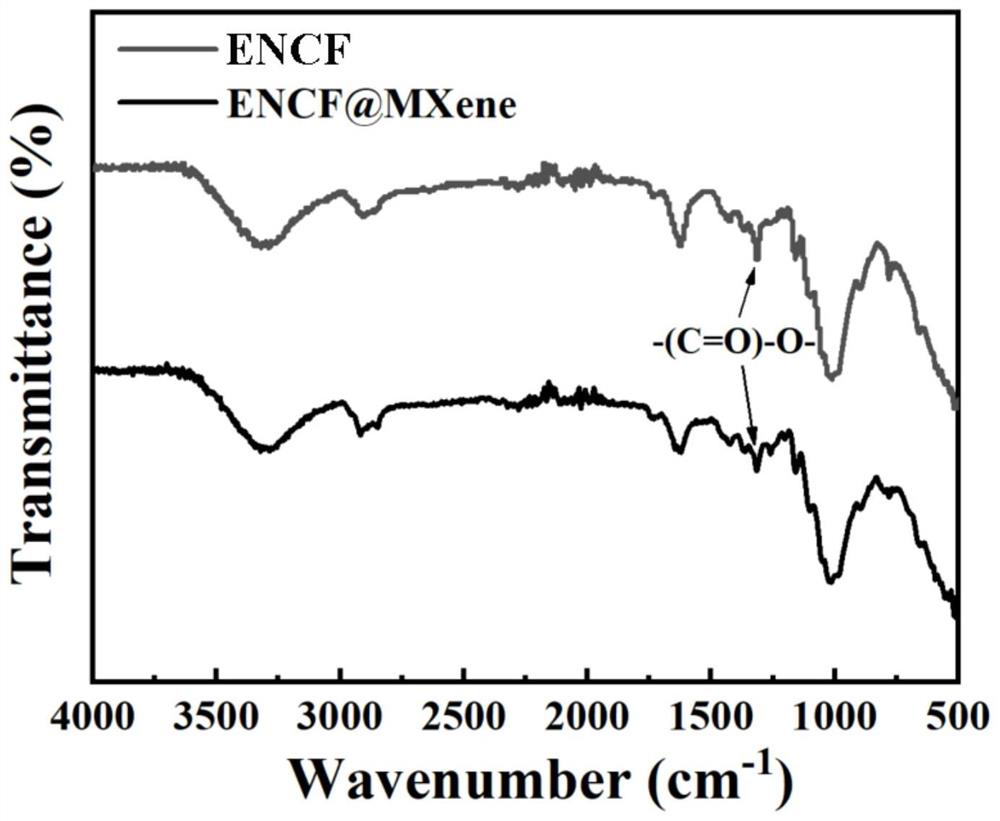

[0034] A kind of preparation method of esterified cellulose loaded MXene high tenacity film, comprises the following steps:

[0035] Step 1. Mix 1g LiF and 40mL of 36% HCl aqueous solution, then slowly add 1.5gTi 3 AlC 2 Obtain solution A, then place solution A in a water bath at 45°C and continue to stir for 24 hours, and finally use a centrifuge with a speed of 3500r / min for centrifugation, and wash with deionized water to obtain an MXene suspension with a pH value of 6 Liquid B;

[0036] Step 2. Soak the poplar wood powder in 80mg / mL NaOH solution and stir at 100°C for 8h. After separation, the treated poplar wood powder is obtained, and then 14g of choline chloride, 12g of oxalic acid and 2g of the treated poplar wood powder are Mix wood flour and stir at 110°C for 3 hours until a viscous liquid D is formed, and finally add deionized water to the viscous liquid D at a volume ratio of 1:10 to obtain a mixed solution E;

Embodiment 2

[0040] A kind of preparation method of esterified cellulose loaded MXene high tenacity film, comprises the following steps:

[0041] Step 1. Mix 1g LiF and 40mL of 36% HCl aqueous solution, then slowly add 1gTi 3 AlC 2 Obtain solution A, then place solution A in a water bath at 45°C and continue to stir for 24 hours, and finally use a centrifuge with a rotation speed of 4000r / min for centrifugation, and wash with deionized water to obtain an MXene suspension with a pH value of 7 Liquid B;

[0042] Step 2, soak the poplar wood powder in the NaOH solution of 100mg / mL and stir at 100°C for 6 hours, obtain the treated poplar wood powder after separation, then mix 14g of choline chloride, 26g of oxalic acid and 4g of the treated poplar wood powder Mix poplar wood powder and stir at 100°C for 4 hours until a viscous liquid D is formed, and finally add deionized water to the viscous liquid D at a volume ratio of 1:12 to obtain a mixed solution E;

[0043] Step 3. Add 2g sodium chl...

Embodiment 3

[0046] A kind of preparation method of esterified cellulose loaded MXene high tenacity film, comprises the following steps:

[0047] Step 1. Mix 2g LiF and 40mL of 36% HCl aqueous solution, then slowly add 2gTi 3 AlC 2 Obtain solution A, then place solution A in a water bath at 45°C and continue to stir for 24 hours, and finally use a centrifuge with a speed of 4000r / min for centrifugation, and wash with deionized water to obtain an MXene suspension with a pH value of 6 Liquid B;

[0048] Step 2. Soak the poplar wood powder in 90mg / mL NaOH solution and stir it at 100°C for 7 hours. After separation, the treated poplar wood powder is obtained, and then 14g of choline chloride, 20g of oxalic acid and 2.8g of oxalic acid are treated. Mix poplar wood powder and stir at 120°C for 5 hours until a viscous liquid D is formed, and finally add deionized water to the viscous liquid D at a volume ratio of 1:13 to obtain a mixed solution E;

[0049] Step 3. Add 3g sodium chlorite and 1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com