Gallium oxide single crystal growth shouldering angle control method and control device

A control method, gallium oxide technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of inability to guarantee the repeatability of single crystal growth, decrease in consistency, etc., to achieve lower requirements and experience dependence, and finished products The effect of improving efficiency and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

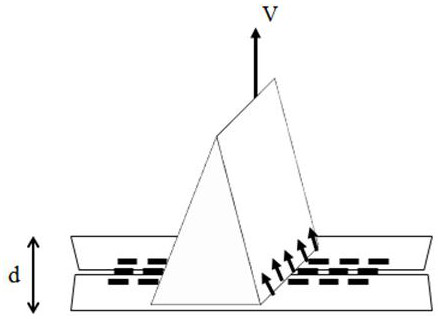

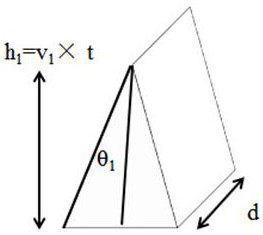

[0078] Example 1: Growth rate v=20mm / h, sampling period T=3 minutes, so the growth height of one sampling period is h 1 = h 2 =0.1cm, initial shoulder angle θ 1 =30º, tanθ 1 = tan30º=0.57.

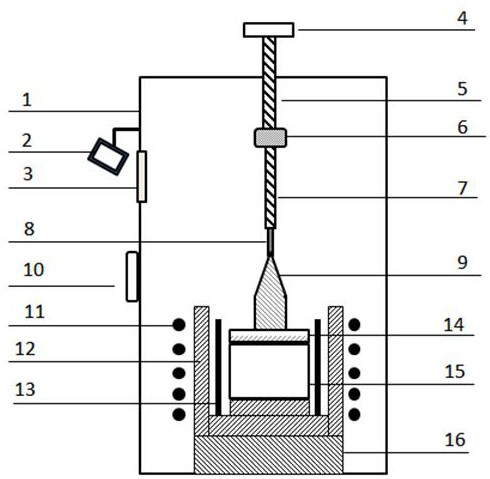

[0079] Step 1: Put the gallium oxide raw material into the crucible 15, place the mold guiding device 14 on the upper edge of the crucible 15, fix the seed crystal 8 on the seed crystal rod 7, align the lower end of the seed crystal 8 with the gap of the mold guiding device 14, And communicate with the raw material in the crucible 15 through the gap, place or install the seed rod, the crucible, the heating element, and the heat preservation structure in place; The eddy current is generated on the crucible, and the heat generated by the heating element 13 gradually melts all the raw materials in the crucible 15, and then waits for seeding;

[0080] Step 2: In the control system 10 in front of the furnace body, pre-set the shoulder angle θ of the crystal 9 1 =30º, growth rate v=20mm / h, ...

Embodiment 2

[0100] Example 2: Growth rate v=5mm / h, sampling period T=6 minutes, so the growth height of one sampling period is h 1 = h 2 =0.05cm, initial shoulder angle θ 1 =15º, tanθ 1 = tan15º=0.26.

[0101] The 1st step: the charging operation process is identical with the 1st step among the embodiment one;

[0102] Step 2: In the control system 10 in front of the furnace body, preset the shoulder angle θ of the crystal 9 1 =15º, growth rate v=5mm / h, sampling period T=6 minutes;

[0103] The 3rd step: the seeding and start pulling operations are the same as the 3rd step in the embodiment one;

[0104] Step 4: The process from the weighing device 6 monitoring the crystal quality to transmitting the data to the control system 10 is the same as the first embodiment. The crystal growth mass m in the last sampling period that can be obtained from the weighing device 1 = 0.16 g, the crystal growth mass m in this sampling period 2 = 0.17 g, according to Figure 6 The equivalent calcu...

Embodiment 3

[0122] Embodiment 3: Growth rate v=10mm / h, sampling period T=12 minutes, so the growth height of one sampling period is h 1 = h 2 =0.2cm, initial shoulder angle θ 1 =45º, tanθ 1 = tan45º=1.

[0123] The 1st step: the charging operation process is identical with the 1st step among the embodiment one;

[0124] Step 2: In the control system 10 in front of the furnace body, preset the shoulder angle θ of the crystal 9 1 =45º, growth rate v=10mm / h, sampling period T=12 minutes;

[0125] The 3rd step: the seeding and start pulling operations are the same as the 3rd step in the embodiment one;

[0126] Step 4: the process from weighing device 6 monitoring crystal quality to transmitting data to control system 10 is the same as embodiment one; the crystal growth quality m in the last sampling period that can be obtained from weighing device 1 = 2.36 g, the crystal growth mass m in this sampling period 2 = 2.92 g, according to Figure 6 The equivalent calculation in , consider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com