Buried sandwich broadband coupling calibration network

A buried, network technology, applied in the direction of radiating element structure, antenna, antenna grounding device, etc., can solve the problems of gain loss, difficult AD sampling, difficult implementation, etc., to achieve strong manufacturability, strong versatility, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

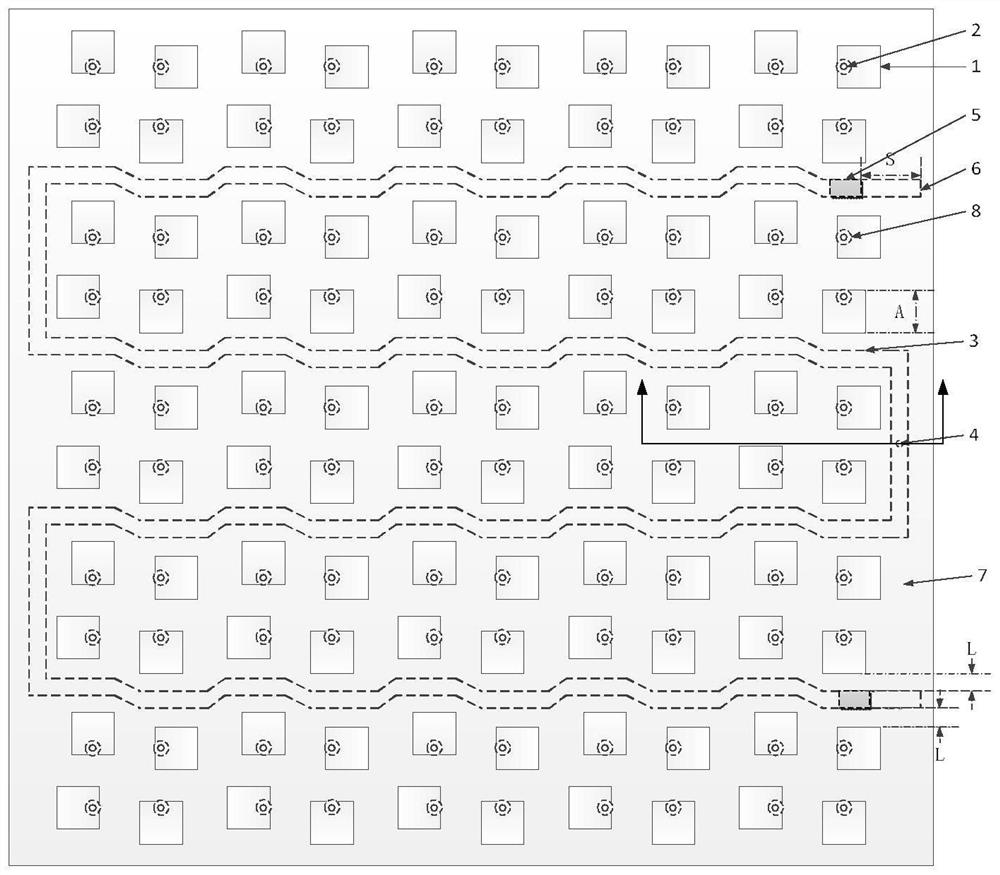

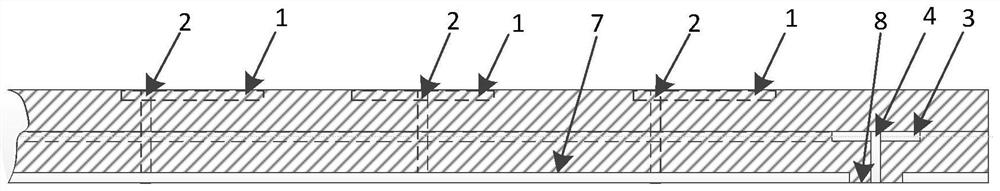

[0011] figure 1 It is the front view of the embedded sandwich broadband coupling calibration network of the present invention;

[0012] figure 2 yes figure 1 Partial cross-section of the centerline of

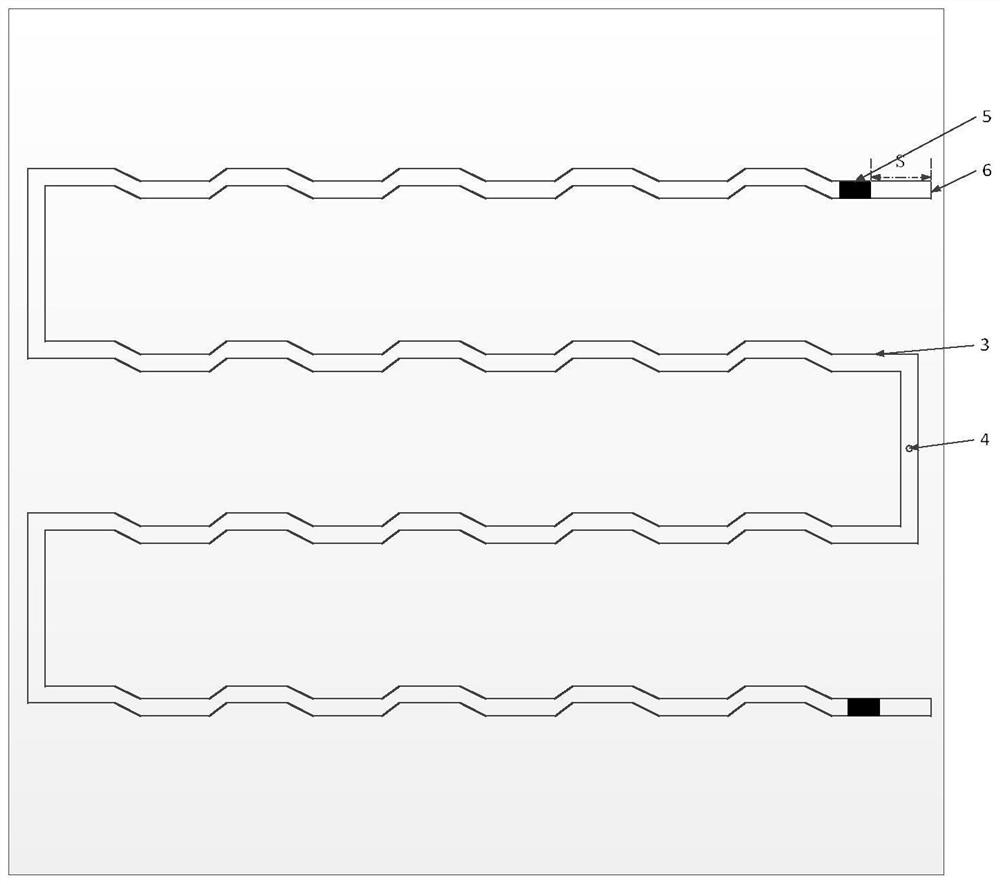

[0013] image 3 yes figure 2 Top view of the bottom dielectric board;

[0014] Figure 4 yes image 3 bottom view of

[0015] In the figure: 1 antenna patch, 2 edge feed point, 3 sandwich microstrip line network, 4 network feed point, 5 buried resistance, 6 microstrip open line, 7 metal floor, 8 floor opening.

[0016] refer to Figure 1-Figure 3 . In the exemplary preferred embodiment described below, a buried sandwich broadband coupling calibration network includes: arranged on the surface of the top layer antenna array printed board surface, the antenna patch 1 arranged in a vertical and horizontal line array dislocation array and set At the edge feed point 2 of the antenna patch 1, the metal floor 7 of the underlying medium with a floor opening 8 is formed, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com