Gob-side entry retaining roadside filling material with adjustable setting, high flow state and high stability and preparation method of gob-side entry retaining roadside filling material

A high stability, filling material technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of slow solidification, high labor intensity, low construction efficiency, etc., and achieve good pressure bearing capacity , high construction efficiency and excellent pumpability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

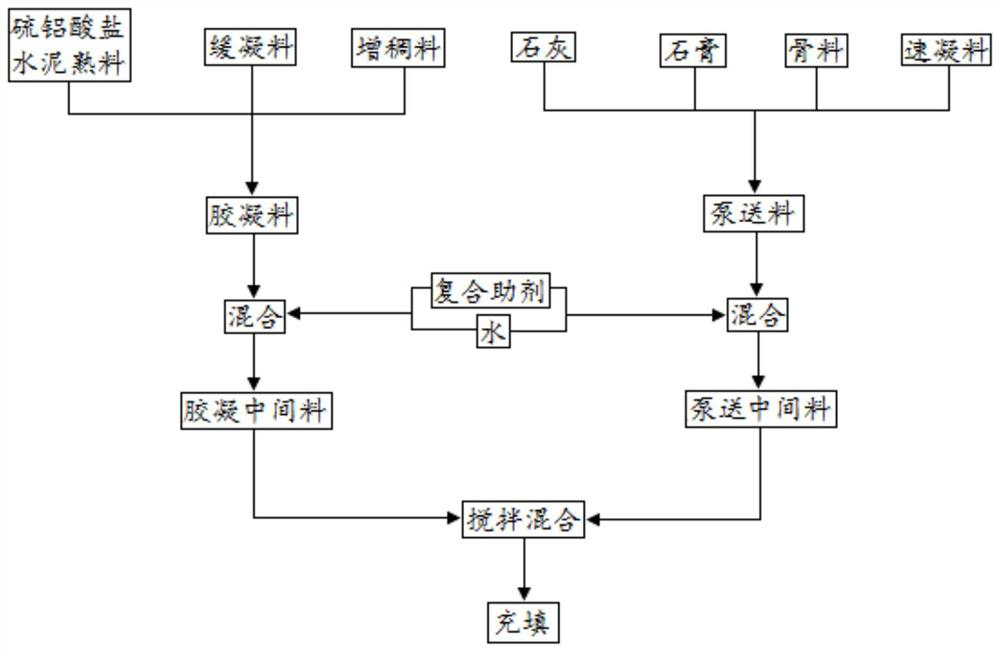

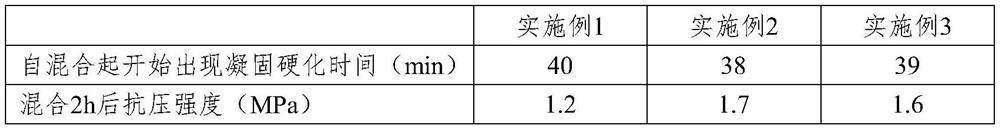

[0049] like figure 1 As shown, the preparation method of filling material beside gob-side entry retaining with adjustable setting height and high stability of flow state:

[0050] Preparation of cementitious material: mix and prepare 190kg of sulphoaluminate cement clinker, 2kg of boric acid, and 1kg of steel fiber, which is counted as one part (193kg);

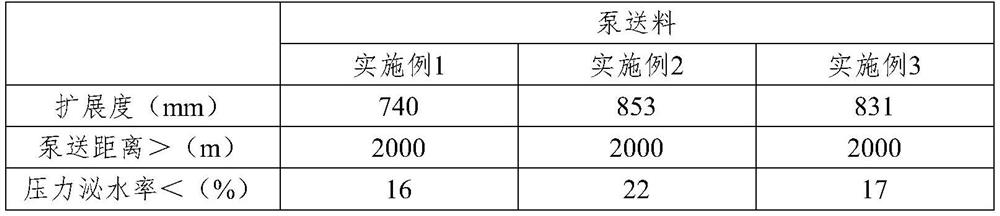

[0051] Preparation of pumping materials: 1050kg of limestone machine-made sand, 50kg of quicklime, 200kg of phosphogypsum, and 22kg of aluminum sulfate are mixed and prepared, which is counted as one part (1322kg);

[0052] Composite additive preparation: mix and prepare polycarboxylate high-efficiency water reducer 8kg, air-entraining agent 1.5kg, and defoamer 1.5kg;

[0053] Mix and stir one portion of the gelling material with 5kg of compound additives and 80kg of water to prepare a gelling intermediate;

[0054] Mix and stir one portion of the pumping material with 6kg of compound additives and 220kg of water to prepare...

Embodiment 2

[0057] like figure 1 As shown, the preparation method of filling material beside gob-side entry retaining with adjustable setting height and high stability of flow state:

[0058] Preparation of cementitious material: mix and prepare 120kg of sulphoaluminate cement clinker, 1kg of boric acid, 1kg of basalt fiber, and 5kg of bentonite, which is counted as one part (127kg);

[0059] Preparation of pumping materials: 1300kg of crushed hard gangue particles, 40kg of quicklime, 160kg of desulfurized gypsum, and 20kg of sodium sulfate are mixed and prepared as one part (1520kg);

[0060] Composite additive preparation: mix and prepare polycarboxylate high-efficiency water reducer 10kg, air-entraining agent 0.5kg, and defoamer 0.5kg;

[0061] Mix and stir one portion of the gelling material with 4kg of compound additives and 60kg of water to prepare a gelling intermediate;

[0062] Mix and stir one portion of the pumped material with 7kg of compound additives and 270kg of water to ...

Embodiment 3

[0065] like figure 1 As shown, the preparation method of filling material beside gob-side entry retaining with adjustable setting height and high stability of flow state:

[0066] Preparation of cementitious material: mix and prepare 140kg of sulfoaluminate cement clinker, 0.5kg of boric acid, and 10kg of magnesium aluminum silicate, count as one part (150.5kg);

[0067] Preparation of pumping materials: 1200kg of river sand, 60kg of quicklime, 200kg of desulfurized gypsum and 20kg of aluminum sulfate are mixed and prepared as one part (1480kg);

[0068] Preparation of compound additives: mix 9kg of polycarboxylate superplasticizer, 1kg of air-entraining agent, and 1kg of defoamer;

[0069] Mix and stir one portion of the gelling material with 5kg of compound additives and 70kg of water to prepare a gelling intermediate;

[0070] Mix and stir one portion of the pumping material with 6kg of compound additives and 250kg of water to prepare a pumping intermediate material;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com