Method for treating printing and dyeing wastewater through iron-manganese/biochar catalytic ozonation

A technology for ozone catalytic oxidation and printing and dyeing wastewater, applied in the field of sewage treatment, can solve the problems of low COD removal efficiency of printing and dyeing wastewater, difficult recovery of heterogeneous catalysts, unstable treatment effect, etc., and achieve good catalytic activity and stability, and reaction conditions. Easy to control, great effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

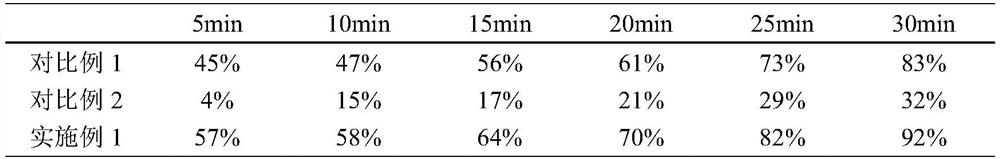

Embodiment 1

[0027] At room temperature, the iron-manganese / biochar catalyst is mixed with the printing and dyeing wastewater, stirred until the mixture is evenly mixed, and the ozone gas is introduced into the aeration liquid after mixing, the diameter of the microporous aerator is 3cm, and the amount of ozone is 30mg / L. The volume of printing and dyeing wastewater is 400ml, and the catalytic reaction at room temperature is 0.5h; the ratio of the iron-manganese / biochar catalyst to the printing and dyeing wastewater is 10:1;

[0028] The iron - manganese / biochar preparation method comprises the following steps:

[0029] 1) Preparation of biochar: dry the surface soil and debris with deionized water for 6h, and roast the dried raw materials under nitrogen protection for 2h at a roasting temperature of 755 °C.

[0030] 2) Pretreatment of biochar: The biochar sieving obtained in step 1) is sequentially washed by 2mol / L sulfuric acid pickling and 2mol / L sodium hydroxide alkali washing, rinsed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com