SiO2 and nitrate microcapsule phase change heat storage composite material and preparation method thereof

A technology of phase change heat storage and composite materials, which is applied in the field of SiO2@nitrate microcapsule phase change heat storage composite materials and its preparation, can solve the problems of easy leakage and low thermal conductivity, and achieve reduced leakage and high thermal conductivity , Solve the effect of corrosion and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

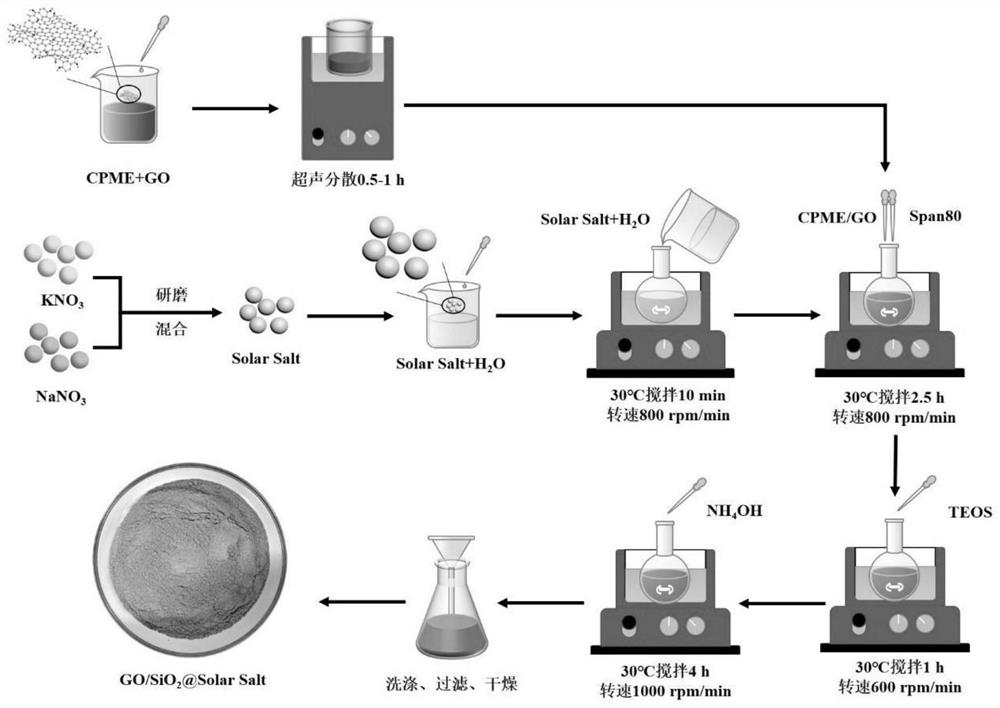

[0054] A GO / SiO 2 @Solar Salt microcapsule phase change heat storage composite material, which is composed of microcapsules and carbon materials. The microcapsules use nitrate as the core material and SiO 2 is the core-shell structure of the shell layer; the two-dimensional GO nanosheets are the modified loading materials of the microcapsules. The specific preparation method includes the following steps:

[0055] (1) Pretreatment: 5g of Solar Salt was completely dissolved in 12ml of deionized water and transferred to a 100ml flask to obtain mixed solution A (aqueous phase solution); 50mg of GO solution (concentration 1wt%) was dispersed in 18ml of CPME Placed in an ultrasonic disperser at 30°C for ultrasonic dispersion for 30min, to obtain a mixed solution B (oil phase solution); the flask (mixed solution A) was placed in a 30°C constant temperature magnetic stirrer and stirred for 10min, with a stirring speed of 800rpm / min, stirring After homogeneous, add mixed solution B a...

Embodiment 2

[0061] A GO / SiO 2 @Solar Salt microcapsule phase change heat storage composite material, which is composed of microcapsules and carbon materials. The microcapsules use nitrate as the core material and SiO 2 is the core-shell structure of the shell layer; the two-dimensional GO nanosheets are the modified loading materials of the microcapsules. The specific preparation method includes the following steps:

[0062] (1) Pretreatment: 5g of Solar Salt was completely dissolved in 12ml of deionized water and transferred to a 100ml flask according to the weight to obtain mixed solution A; 100mg of GO (2wt%) was dispersed in 18ml of CPME and placed in an ultrasonic disperser at 30°C Ultrasonic dispersion was carried out for 40 min to obtain mixed solution B, which was set aside for use; the flask (mixed solution A) was placed in a constant temperature magnetic stirrer at 30°C and stirred for 10 min, and the stirring speed was 800 rpm / min. After stirring evenly, mixed solution B and 1...

Embodiment 3

[0068] A GO / SiO 2 @Solar Salt microcapsule phase change heat storage composite material, which is composed of microcapsules and carbon materials. The microcapsules use nitrate as the core material and SiO 2 is the core-shell structure of the shell layer; the two-dimensional GO nanosheets are the modified loading materials of the microcapsules. The specific preparation method includes the following steps:

[0069] (1) Pretreatment: 5g Solar Salt was completely dissolved in 12ml deionized water and transferred to a 100ml flask according to the weight to obtain mixed solution A; 150mg GO (3wt%) was dispersed in 18ml CPME and placed in an ultrasonic disperser at 30°C Ultrasonic dispersion was carried out for 30 min to obtain mixed solution B, which was set aside for use; the flask (mixed solution A) was placed in a constant temperature magnetic stirrer at 30°C and stirred for 10 min, and the stirring speed was 800 rpm / min. After stirring evenly, mixed solution B and 1.5 ml of Spa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com