Preparation method of ultraviolet aging resistant textile fabric added with attapulgite

A technology of anti-ultraviolet aging and attapulgite, which is applied in the field of textile fabrics to achieve long-lasting excellent anti-ultraviolet aging performance, improved anti-ultraviolet performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

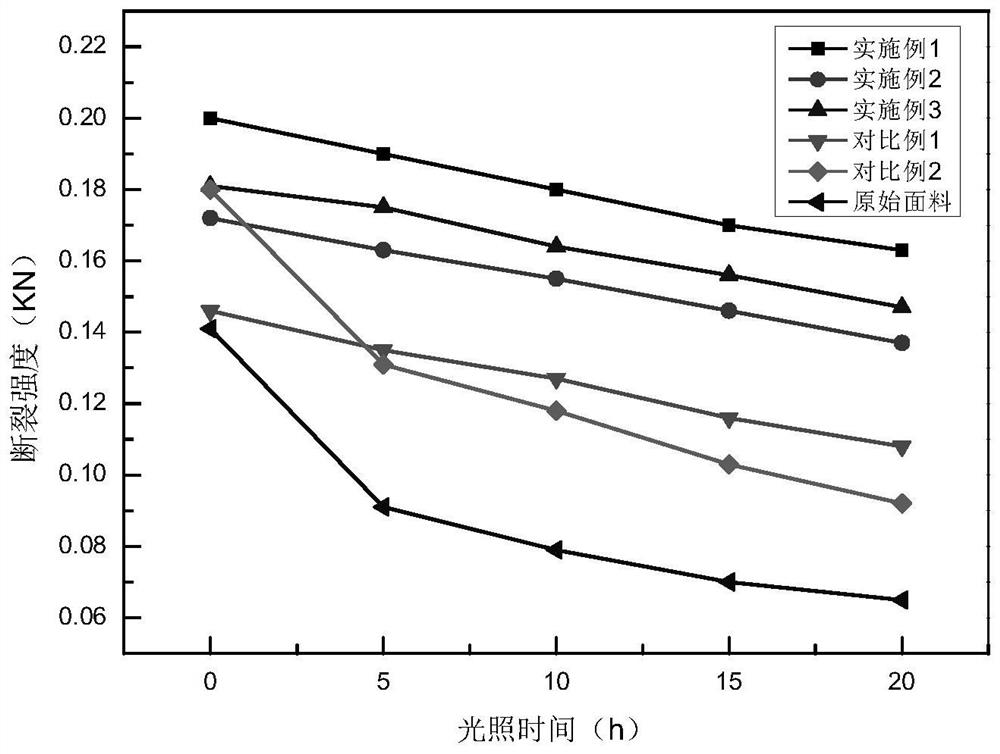

Examples

Embodiment 1

[0023] A preparation method of adding attapulgite anti-ultraviolet aging textile fabric, the specific steps are as follows:

[0024] (1) Preparation of zinc and cerium composite carbonate: adding 50 ml of zinc nitrate solution with a concentration of 2 mol / L and 104 ml of a cerium sulfate solution with a concentration of 0.5 mol / L into the reactor, stirring evenly, and warming up to 60 ° C, While stirring, add 152 ml of potassium carbonate solution with a concentration of 1 mol / L, after adding, continue to keep stirring for 2 hours, filter, and wash with deionized water until the conductivity of the filtrate is 60 μs / cm, dry and pulverize to obtain zinc and cerium. Complex carbonate.

[0025] (2) Preparation of finishing solution: add 100g of polyethylene glycol 400, 100g of glycerol and 800g of deionized water to the reaction kettle to prepare a mixed solution, and the zinc and cerium composite carbonate prepared in step (1), 48g of attapulgite The stone was added to the mix...

Embodiment 2

[0029] A preparation method of adding attapulgite anti-ultraviolet aging textile fabric, the specific steps are as follows:

[0030] (1) Preparation of zinc and cerium composite carbonate: adding 400ml of zinc sulfate solution with a concentration of 0.5mol / L and 25ml of a cerium nitrate solution with a concentration of 2mol / L into the reactor, stirring evenly, and warming up to 80°C, While stirring, add 113 ml of sodium bicarbonate solution with a concentration of 2 mol / L, after adding, continue to keep stirring for 1 h, filter, and wash with deionized water until the conductivity of the filtrate is 90 μs / cm, dry, pulverize, and obtain zinc, Cerium composite carbonate.

[0031] (2) Preparation of finishing liquid: 150g of polyethylene glycol 400, 150g of glycerol and 700g of deionized water were added to the reaction kettle to prepare a mixed solution, and the zinc, cerium composite carbonate, 24g attapulgite prepared in step (1) The stone was added to the mixed solution and...

Embodiment 3

[0035] A preparation method of adding attapulgite anti-ultraviolet aging textile fabric, the specific steps are as follows:

[0036] (1) Preparation of zinc and cerium composite carbonate: add 100 ml of zinc chloride solution with a concentration of 1.5 mol / L and 46 ml of a cerium chloride solution with a concentration of 1.5 mol / L into the reactor, stir evenly, and heat up to 70°C, while stirring, add 123ml of sodium carbonate solution with a concentration of 1.5mol / L, after adding, continue to keep stirring for 1.5h, filter, and wash with deionized water until the conductivity of the filtrate is 70μs / cm, dry, pulverize, Preparation of zinc, cerium composite carbonate.

[0037] (2) Preparation of finishing solution: 150g of polyethylene glycol 400, 100g of glycerol and 750g of deionized water were added to the reaction kettle to prepare a mixed solution, and the zinc and cerium composite carbonate prepared in step (1), 32g of attapulgite The stone was added to the mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com