Psoralen/ligustrazine microemulsion and microemulsion gel as well as preparation method and application of psoralen/ligustrazine microemulsion and microemulsion gel

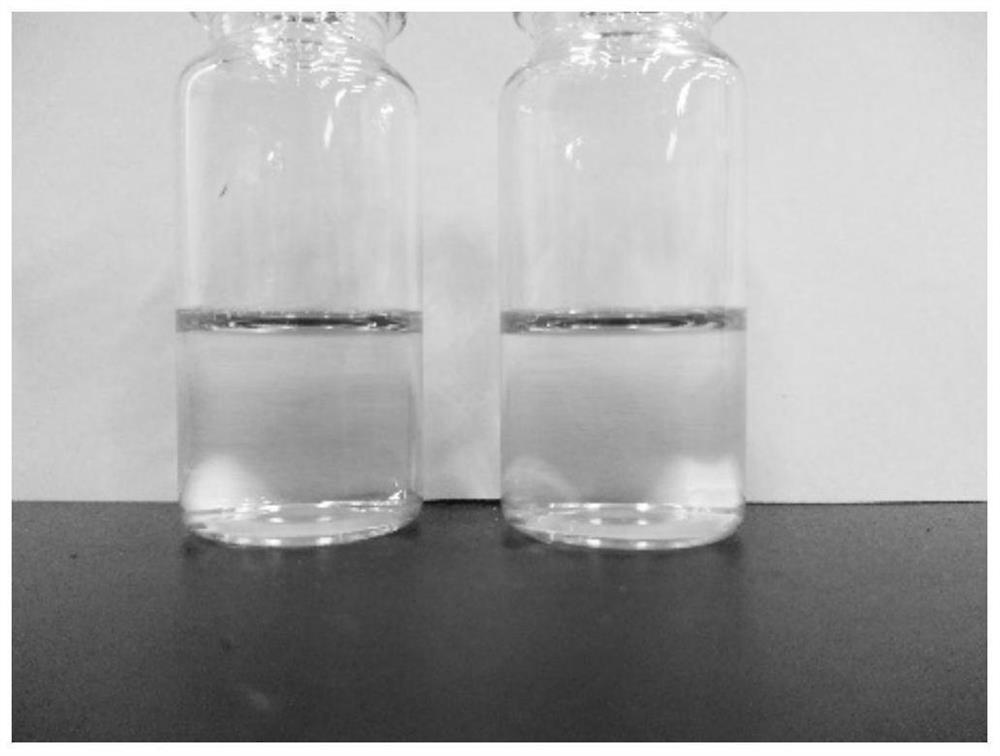

A technology of psoralen and microemulsion gel, which is applied in the field of preparation of pharmaceutical preparations, can solve the problems of large side effects and poor curative effect of vitiligo, and achieve the effects of easy transportation and storage, uniform and transparent appearance, and high gel viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

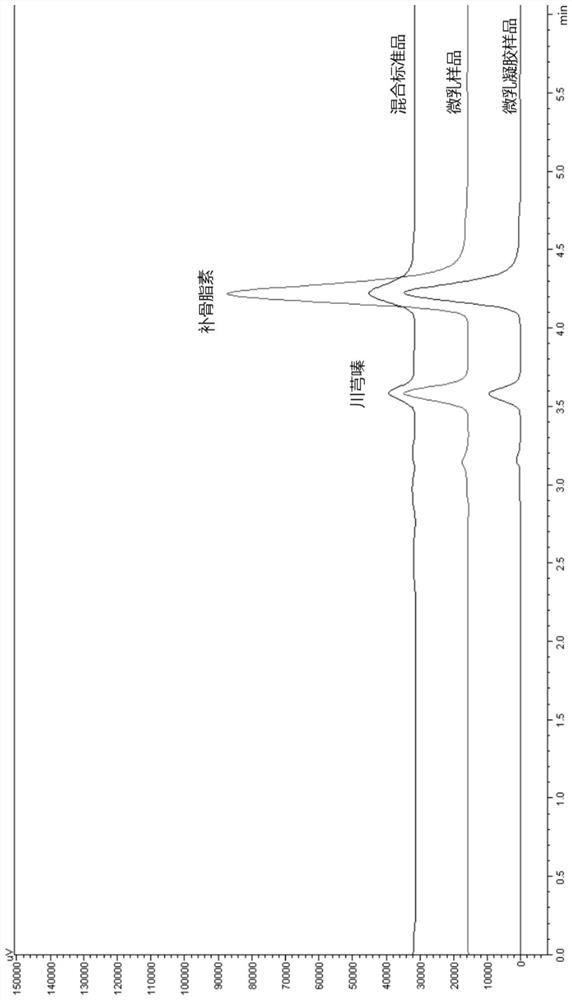

[0048] A kind of psoralen / ligustrazine microemulsion, its preparation method comprises the following steps:

[0049] (1) 28.2mg psoralen, 241.1mg ligustrazine, 2.135g Tween 80 and 2.135g isopropanol were vortex-mixed until completely dissolved to obtain a mixed solution;

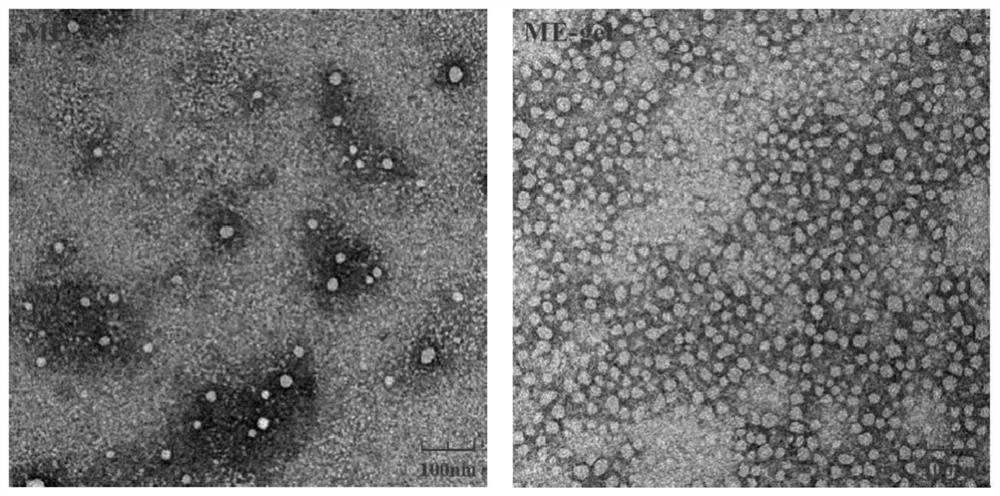

[0050] (2) Add 1.54g of polyethylene glycol glycerol oleate to the mixed solution, stir magnetically for 30min at 35°C, then add 4.19g of pure water dropwise, stir for 30min, to obtain psoralen / ligustrazine microparticles milk;

[0051] A kind of psoralen / ligustrazine microemulsion gel, its preparation method comprises the following steps:

[0052] Take 101.5 mg of Carbomer 940 in a beaker, add 50 mL of pure water, leave it for 12 hours to fully swell, then add the above-mentioned psoralen / Ligustrazine microemulsion, and stir at 35°C for 30 minutes to obtain psoralen / Ligustrazine Zine microemulsion gel; volume ratio of psoralen / ligustrazine microemulsion and swelled carbomer 940 was 1:1.

Embodiment 2

[0054] A kind of psoralen / ligustrazine microemulsion, its preparation method comprises the following steps:

[0055] (1) 20.4mg psoralen, 153.6mg ligustrazine, 1.536g Tween 80 and 1.536g isopropanol were vortex-mixed until completely dissolved to obtain a mixed solution;

[0056] (2) Add 1.024g of polyethylene glycol glycerol oleate to the mixed solution, stir magnetically for 30min at 35°C, then add 5.971g of pure water dropwise, stir for 30min, to obtain psoralen / ligustrazine microparticles milk;

[0057] A kind of psoralen / ligustrazine microemulsion gel, its preparation method comprises the following steps:

[0058] Take 101.5 mg of Carbomer 940 in a beaker, add 100 mL of pure water, leave it for 12 hours to fully swell, then add the above-mentioned psoralen / Ligustrazine microemulsion, and stir at 35°C for 30 minutes to obtain psoralen / Ligustrazine The volume ratio of psoralen / ligustrazine microemulsion and swelled carbomer 940 was 1:0.8.

Embodiment 3

[0060] A kind of psoralen / ligustrazine microemulsion, its preparation method comprises the following steps:

[0061] (1) 30.7mg psoralen, 256.05mg ligustrazine, 2.56g Tween 80 and 2.56g isopropanol were vortex-mixed until completely dissolved to obtain a mixed solution;

[0062] (2) Add 2.048g of polyethylene glycol glycerol oleate to the mixed solution, stir magnetically for 30min at 35°C, then add 2.785g of pure water dropwise, and stir for 30min to prepare psoralen / ligustrazine microparticles. milk;

[0063] A kind of psoralen / ligustrazine microemulsion gel, its preparation method comprises the following steps:

[0064] Take 101.5 mg of Carbomer 940 in a beaker, add 34 mL of pure water, leave it for 12 hours to fully swell, then add the above-mentioned psoralen / Ligustrazine microemulsion, and stir at 35°C for 30 minutes to obtain psoralen / Ligustrazine Zine microemulsion gel; volume ratio of psoralen / ligustrazine microemulsion and swelled carbomer 940 was 1:1.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com