Polyester film

A technology of polyester film and polyester thick sheet, which is applied in the field of polyester film, can solve the problems that the reel cannot be added automatically, the polyester film is uniformly rewound, and the efficiency is reduced, so as to achieve low shrinkage and uniform thickness , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

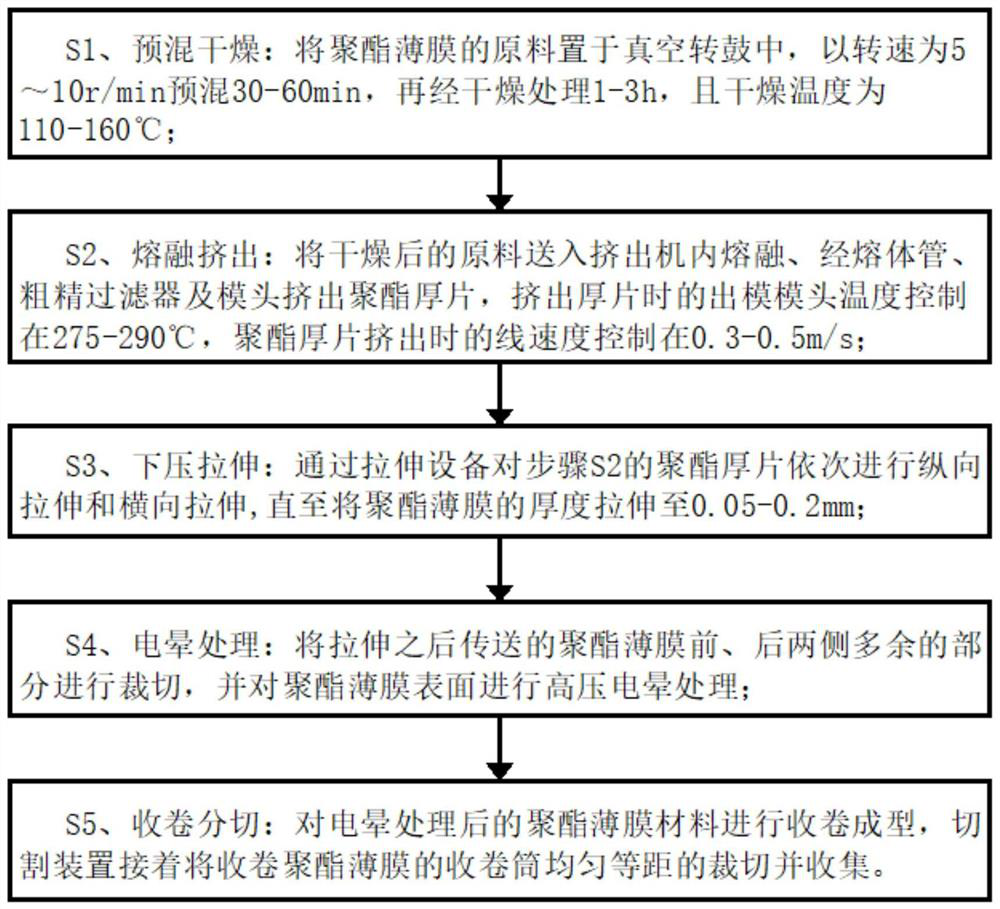

[0050] A polyester film such as figure 1 As shown, its preparation process includes the following:

[0051] S1. Pre-mixing and drying: The raw materials of the polyester film are placed in a vacuum drum, pre-mixed for 30 minutes at a rotational speed of 5r / min, and then dried for 3 hours, and the drying temperature is 110°C;

[0052] S2. Melt extrusion: send the dried raw material into the extruder to melt, extrude polyester thick sheet through the melt tube, coarse and fine filter and die, and control the temperature of the die when extruding the thick sheet At 275°C, the linear speed of polyester thick sheet extrusion is controlled at 0.3m / s;

[0053] S3, lower pressure stretching: the polyester thick sheet in step S2 is sequentially stretched longitudinally and transversely by stretching equipment until the thickness of the polyester film is stretched to 0.05mm;

[0054] S4, corona treatment: cut the excess parts on the front and rear sides of the polyester film conveyed ...

Embodiment 2

[0058] A polyester film such as figure 1 As shown, its preparation process includes the following:

[0059] S1. Pre-mixing and drying: The raw materials of the polyester film are placed in a vacuum drum, pre-mixed for 40 minutes at a rotational speed of 57 r / min, and then dried for 2 hours, and the drying temperature is 130 °C;

[0060] S2. Melt extrusion: send the dried raw material into the extruder to melt, extrude polyester thick sheet through the melt tube, coarse and fine filter and die, and control the temperature of the die when extruding the thick sheet At 280°C, the linear speed of the polyester thick sheet extrusion is controlled at 0.4m / s;

[0061] S3, lower pressure stretching: the polyester thick sheet in step S2 is longitudinally stretched and transversely stretched in turn by stretching equipment, until the thickness of the polyester film is stretched to 0.1mm;

[0062] S4, corona treatment: cut the excess parts on the front and rear sides of the polyester fi...

Embodiment 3

[0066] A polyester film such as figure 1 As shown, its preparation process includes the following:

[0067] S1. Pre-mixing and drying: The raw materials of the polyester film are placed in a vacuum drum, pre-mixed for 30 minutes at a rotational speed of 10 r / min, and then dried for 1 hour, and the drying temperature is 160 °C;

[0068] S2. Melt extrusion: send the dried raw material into the extruder to melt, extrude polyester thick sheet through the melt tube, coarse and fine filter and die, and control the temperature of the die when extruding the thick sheet At 290℃, the linear speed of polyester thick sheet extrusion is controlled at 0.5m / s;

[0069] S3, lower pressure stretching: the polyester thick sheet in step S2 is sequentially stretched longitudinally and transversely by stretching equipment until the thickness of the polyester film is stretched to 0.2 mm;

[0070] S4, corona treatment: cut the excess parts on the front and rear sides of the polyester film conveyed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com